Overview

Through this section, you can quickly know components of 200 Series.

200 Series include the following models:

- NK260 integrated CNC system (hereinafter referred to as NK260)

- NK280 integrated CNC system (hereinafter referred to as NK280)

- NK280B integrated CNC system (hereinafter referred to as NK280B)

You can see Model Selection for how to select the desired one among them.

All of them consist of hardware and software:

Hardware

- NK260 / NK280 / NK280B host

- PCBA EX9A terminal board

- DB9M/F cables

Note: For NK280B, the used terminal board is Lambda 5M RJ45.

Software

NK260 / NK280 / NK280B software

See Main Software Interface for the introduction to the main interface of the software.

Model Selection

You can select the desired integrated CNC system that matches with the structure of your machine tool and machining demands according to its application:

NK260

Three-axis engraving machine

NK280

Three + one axis (double Y / single Y + single servo magazine)

Four-axis simultaneous movement, double Z engraving, three + two axis (single Y + double servo magazine, double Y + single servo magazine, double Y + double servo magazine)

Five-axis (four + one) engraving machine

NK280B

Three-axis bilateral milling machine

Three-axis bus control, three + one axis (double Y / single Y + single servo magazine)

Bus control four-axis simultaneous movement, double Z engraving, three + two axis (single Y + double servo magazine, double Y + single servo magazine, double Y + double servo magazine)

Host

This section mainly takes NK260 host as an example, and explains the differences among these CNC integrated systems separately as well.

Front View

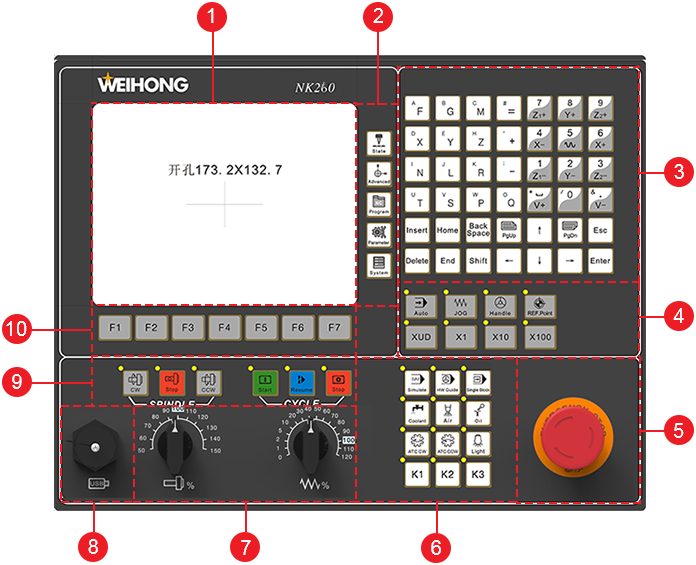

Front view of the host is as follows:

- Display screen

- Main function buttons

- Alpha-numeric keypad

- Mode buttons

- E-stop button

- Auxiliary function buttons

- Override switches

- USB interface

- Movement control buttons

- Operational buttons

Main Function Buttons

They are used to switch to the following functional areas:

: to enter into State functional area.

: to enter into State functional area. : to enter into Advanced functional area.

: to enter into Advanced functional area. : to enter into Program functional area.

: to enter into Program functional area. : to enter into Parameter functional area.

: to enter into Parameter functional area. : to enter into System functional area.

: to enter into System functional area.

Alpha-numeric Keypad

It consists of the set of keys for operating the integrated CNC system. And its use is generally the same with that of the computer keyboard, except the following:

Enter an alphabet

For NK260, directly press the button to enter the alphabet on the left-upper part, and press Shift and an alphabet key to enter the alphabet on the right-lower part.

For NK280 / NK280B, the opposite is true.

Numeric keys are used as axis direction keys in Manual mode.

- Only press the axis direction key to move the axis at jog speed.

- Press the axis direction key and numeric key 5 together to move the axis at rapid jog speed.

Mode Buttons

They are used to switch among the following modes:

: in this mode, the machine tool will automatically run the program file.

: in this mode, the machine tool will automatically run the program file. : in this mode, it is convenient to return to the machine origin or set datum.

: in this mode, it is convenient to return to the machine origin or set datum. : in this mode, the machine tool will keep running until you release the button.

: in this mode, the machine tool will keep running until you release the button. : in this mode, the machine tool will be controlled by handwheel.

: in this mode, the machine tool will be controlled by handwheel. : in this mode, the machine tool only will move 0.001(mm), 0.01(mm), 0.1(mm) or a customized step size.

: in this mode, the machine tool only will move 0.001(mm), 0.01(mm), 0.1(mm) or a customized step size.

The last three modes are referred as Manual mode.

E-stop Button

It is used to stop the machine tool completely when it is in danger by triggering the emergency alarm.

When the danger is cleared, you can remove the alarm by rotating the button in the clockwise direction.

Auxiliary Function Buttons

They are used to turn on or off the following frequently used ports:

: used to turn on/off blowing.

: used to turn on/off blowing. : used to turn on/off the lubricant.

: used to turn on/off the lubricant. : used to turn on/off the light.

: used to turn on/off the light. : used to turn on/off the coolant.

: used to turn on/off the coolant. : not customized yet.

: not customized yet. ~

~  : used to customize function.

: used to customize function.

Override Switches

They include the following switches:

: used to adjust the spindle override form 50% ~ 150%.

: used to adjust the spindle override form 50% ~ 150%. : used to adjust the feed override from 0% ~ 120%.

: used to adjust the feed override from 0% ~ 120%.

Movement Control Buttons

They are used to control the movement of the machine tool:

/

/  : used to start / stop the rotation of the spindle.

: used to start / stop the rotation of the spindle. /

/  /

/  : used to control machining.

: used to control machining.See Execute machining for details.

Operational Buttons

They are used to execute the corresponding operation in the display screen.

~

~

Rear View

The rear view of NK260, NK280 and NK280B differs:

NK260

NK280

NK280B

Main Software Interface

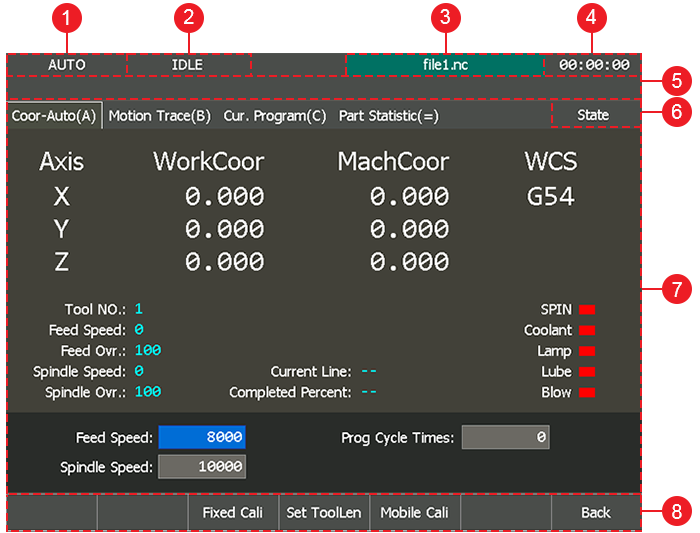

The interactive operational interface of NK260, NK280 and NK280B are almost the same:

- Show the current mode, including AUTO, JOG, etc.

- Show the current status of the machine tool, including IDLE, RUNNING, etc.

- Show the name of the currently loaded program file or the currently loaded program task.

- Show the machining time.

- Show information such as working process or alarms.

- Show the name of the current functional button.

- Show child interfaces corresponding to each main function button.

- Show commands corresponding to F1 ~ F7 on different operational interface.