Configure Machine Parts

It is used to set machine parts by NcConfig software, so that you can customize related functions in the customized bar of NcStudio software.

Machine parts include M codes, panels, double stations, tool magazine, saw, gang drill, material loading and unloading, handwheel and press wheel.

To configure machine parts, do the following:

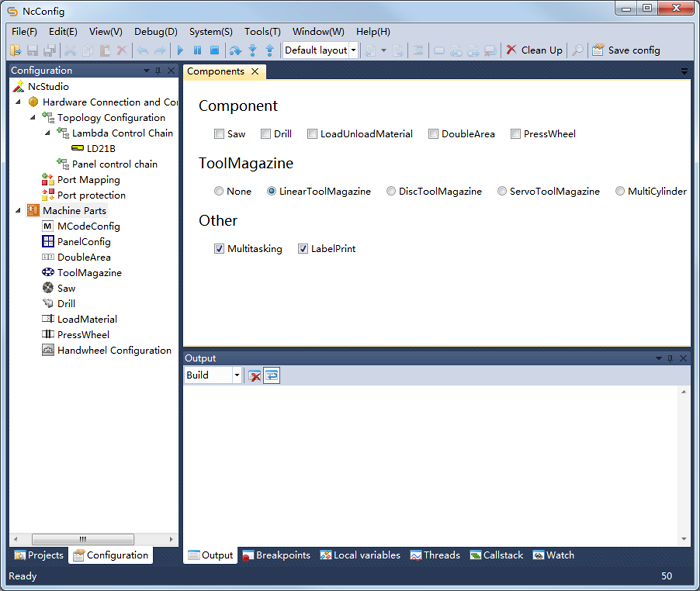

In Configuration page in the left, click NcStudio, and double click Machine Parts. Components page shows:

Check the target machine parts.

After the target machine parts are checked, you can customize the following functions in the related software:

NcTune software:

- Doing commissioning for the tool magazine

- Setting the gang drill

- Setting tool compensation

- Setting parameters for loading and unloading

NcStudio software:

Do the following based on your needs:

Configure M Codes

It is used to configure M codes, so as to control the movement of the machine tool and the port status.

Note: Please configure M codes based on the selected machine parts, instead of configuring them freely.

M codes include the following:

Function: these M codes are used to control the movement of the machine tool:

Code Meaning Code Meaning MCode 13 Drill on MCode 15 Drill off MCode 100 Load MCode 200 Unload MCode 300 Load & unload MCode 753 Press wheel on MCode 754 Press wheel off MCode 23 Saw on MCode 25 Saw off MCode 26 Saw blade retracted MCode 27 Saw blade swings in X direction MCode 28 Saw blade swings in Y direction Valve: these M codes are used to control the port status:

Code Meaning Code Meaning MCode 701 Vacuum adsorption on MCode 702 Vacuum adsorption off MCode 703 Front pos cylinder on MCode 704 Front pos cylinder off MCode 707 Left pos cylinder on MCode 708 Left pos cylinder off MCode 709 Right pos cylinder on MCode 710 Right pos cylinder off MCode 711 Back push cylinder on MCode 712 Back push cylinder off MCode 713 Right push cylinder on MCode 714 Right push cylinder off MCode 715 Left push cylinder on MCode 716 Left push cylinder off MCode 719 Unload cylinder on MCode 720 Unload cylinder off MCode 721 Load cylinder on MCode 722 Load cylinder off MCode 723 Load blow on MCode 724 Load blow off MCode 725 Vacuum destroy on MCode 726 Vacuum destroy off

To configure M codes, do the following:

In Configuration page in the left, double click MCodeConfig. MCodeConfig page shows.

To modify the target M code, select the target function, click on the target input box of MCode column, and input a value.

Configure Panels

It is used to configure panels, so that buttons of related functions will show in the customized bar of NcStudio software.

The configurable function buttons include: spindle switch, one key back, to fixed position, area 1/2 start, area 1/2 pos cylinder, area 1/2 vacuum adsorption, area 1/2 vac on, area 1 dust removal, area 1 pos cylinder, dust removal cylinder, drill start, drill cylinder, drill reset, load material, unload material, load & unload material, unload measure start, load cylinder, unload cylinder, vacuum adsorb, vacuum destroy, load blow, load adsorb, front/right/left pos cylinder, back/left/right push cylinder, press switch, saw T31/T32, saw ON, saw cylinder, manual unclamp tool, tool magazine cylinder, and dust cover.

Before configuring panels, make sure related machine parts have been checked in Components page.

To configure panels, do the following:

In Configuration page in the left, double click PanelConfig. PanelConfig page shows.

To configure a button for the target function in the customized bar of NcStudio software, click the target dropdown box, and select a target function.

Configure Double Stations

It is used to use two stations for machining by configuring related ports, in which the system can directly start machining on station 2 after machining on station 1 finishes, so as to save time of loading and unloading and improve machining efficiency.

To configure double stations, do the following:

In Configuration page in the left, double click DoubleArea. DoubleArea page shows.

Double click the target port in PhysicalAddress column, and select the target Lambda terminal board and port.

Configure the Tool Magazine

It is used to configure the target type of tool magazine and multi-cylinder.

The supported tool magazines include the following:

- Linear tool magazine

- Disk tool magazine

- Servo tool magazine

To configure the tool magazine, do the following:

In Configuration page in the left, double click Machine Parts. Components page shows.

In ToolMagazine area, select the target magazine type.

In Configuration page in the left, double click ToolMagazine. ToolMagazine page shows:

If the type of tool magazine is linear tool magazine, set parameter Tool magazine capacity.

Tool magazine capacity: the total number of tools in tool magazine.

If the type of tool magazine is disk tool magazine, set the following parameters:

Tool magazine capacity: the total number of tools in the tool magazine.

Count tool overtime(ms): the maximum time to wait for the tool counting signal.

If the type of tool magazine is servo tool magazine, set the following parameters:

Tool magazine capacity: the total number of tools in the tool magazine.

Servo axis index: the axis number of the servo axis.

If the type of tool magazine is multi-cylinder, select a cylinder type and set parameter Cylinder count:

Multi-cylinder single-fre: one inverter controls the start and stop of several spindles.

Multi-cylinder multi-fre: one Z-axis equips with two or four cylinders, and several inverters control the start and stop of several spindles.

Four-cylinder double-fre: one Z-axis equips with four cylinders, and two inverters control the start and stop of several spindles.

Double click the target port in PhysicalAddress column, and select the target Lambda terminal board and port.

Configure the Saw

To configure the saw, do the following:

In Configuration page in the left, double click Saw. Saw page shows.

Set parameters Saw axis index.

Double click the target port in PhysicalAddress column, and select the target Lambda terminal board and port.

Configure the Gang Drill

To configure the gang drill, do the following:

In Configuration page in the left, double click Drill. Drill page shows.

Set parameter Drill start number.

Double click the target port in PhysicalAddress column, and select the target Lambda terminal board and port.

Configure Loading and Unloading

It is used to make sure that the physical address is the same with the logic address, so as to control the movement of the front positioning cylinder.

To configure loading and unloading, do the following:

In Configuration page in the left, double click LoadMaterial. LoadMaterial page shows.

Select a type for loading and unloading:

Standard load & unload material: load and unload a group of boards.

Multi-plate load & unload material: load and unload two or four groups of boards.

Double click the target port in PhysicalAddress column, and select the target Lambda terminal board and port.

Example

There is only one front positioning cylinder for three types of boards, which is connected to Y10 on Lambda terminal board. Thus, you need to set the logic address of front positioning cylinder for board 1, board 2 and board 3 to Y10.

Configure the Handwheel

After configuring the handwheel, you can control the movement of the machine tool by the handwheel or enable handwheel guide.

To configure the handwheel, do the following:

In Configuration page in the left, double click Handwheel configuration. Handwheel configuration page shows.

Change Turn on switch to ON status.

Configure the Press Wheel

After configuring the press wheel, the phenomenon that the board deviates during machining can be avoided.

To configure the press wheel, do the following:

In Configuration page in the left, double click PressWheel. PressWheel page shows.

Double click the target port in PhysicalAddress column, and select the target Lambda terminal board and port.