Set Tool Compensation

Tool compensation includes tool length compensation and tool radius compensation.

The cutting part actually involved is the tool nose or the cutting edge which has dimensional variation with the tool center or the related point of the tool rest, so the CNC system has to compute the corresponding coordinates of the tool center or the related point of the tool rest according to the actual coordinate position of the tool rest or the cutting edge (namely the actual coordinate position of the part profile), which is called tool compensation.

Note: Please set tool compensation in the help of the technician.

Before setting tool compensation, set the following parameters to Yes:

- Enable Tool Length Compensation

- Enable Tool Radius Compensation

To set tool compensation, do the following:

In the upper right corner of the main interface of NcStudio software, click the hamburger menu

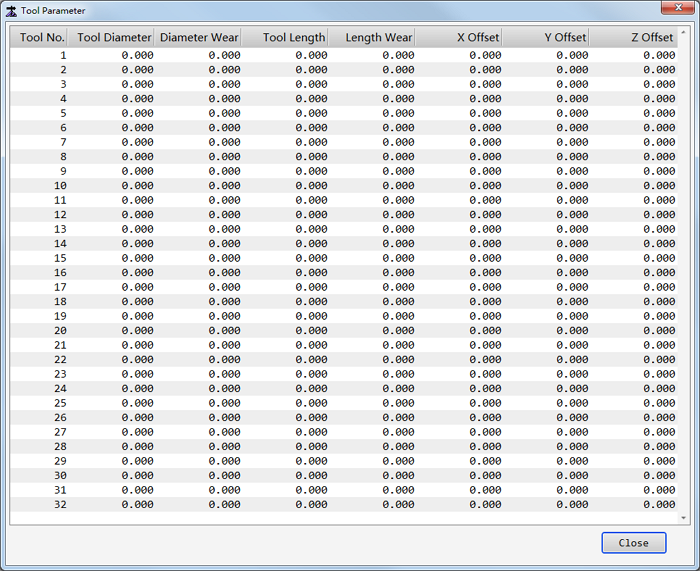

→ Tool Parameter. Tool Parameter dialog box pops up:

→ Tool Parameter. Tool Parameter dialog box pops up:

Set the following parameters for the target tool:

- Tool Diameter: the diameter of the current tool.

- Diameter Wear: the diameter wear of the current tool.

- Tool Length: the length of the current tool.

- Length Wear: the length wear of the current tool.

- X / Y / Z Offset: the offset of X-axis / Y-axis / Z-axis.