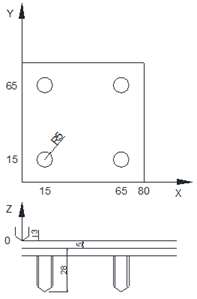

Programming Example 4

Sketch for machining file is as follows:

The corresponding programming is as follows:

N01 G92 X0 Y0 Z0 'workpiece coordinates system establishment

N02 G91 G00 X-35 Y15 M04 S600 M08 'incremental coordinates adopted, rapid traverse to X-35, Y15, spindle CCW at 600 rpm, and coolant on

N03 G43 G00 Z0 H01 'tool length compensation on

N04 G74 X50 Y0 Z-28 R-5 P1000 F1000 L2 'CCW tapping at 1000mm/min, tapping depth 28mm, dwell for 1s at the bottom of the hole,

executed twice

N05 G00 X-50 Y50 'rapid traverse to X15, Y65, and start tapping

N06 G00 X50 'rapid traverse to X65, Y65, and start tapping

N07 G80 'hole machining cance

N08 G00 X-65 Y-65 'rapid traverse to X0, Y0

N09 G49 M05 M09 M30 'length compensation cancel, spindle stop, coolant off, end of program and return to the program header