G76 Fine Boring Cycle

Format

G76 X_Y_Z_R_Q_P_F_K_

CAUTION:

Command G76 is not supported at the moment.

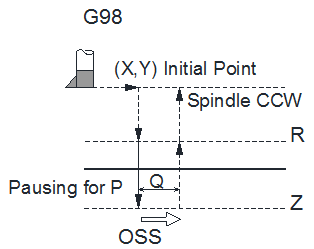

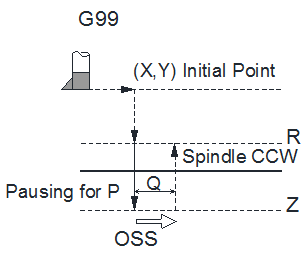

Machining Process

Machining process of G76 is as illustrated as follows:

- The tool moves to the specified hole position (X, Y) at G00 speed.

- The tool goes down to the specified point R at G00 speed.

- The tool moves down to point Z at the bottom of the hole at G01 speed.

- The tool pauses for P.

- Oriented spindle stop is executed.

- The tool shifts cutting depth Q (the offset distance).

- The tool returns to the initial point (G98) or point R (G99) at G00 speed.

- The spindle rotates CCW.

Programming Example

F1200 S600

M03 'spindle CW on

G90

G00 X0 Y0 Z10 'move to the initial point

G17

G90 G99 'specify the coordinates of point R, point Z and hole 1, with the displacement at the bottom of

hole as 2.0, dwell time as 5s, and machining speed as 800

G76 X5 Y5 Z-10 R-5 Q2 P5000 F800

X25 'hole 2

Y25 'hole 3

G98 X5 'hole 4, and set to return to initial point

X10 Y10 Z-20 'hole 5, and specify the new point Z as -20.0

G80

M05 'spindle stops

M02

Warning: As a modal value requested in G76 cycle, Q must be specified carefully, because it is also used in G73/G83.