G83 Peck Drilling Cycle for Deep Holes

Format

G83 X_Y_Z_R_Q_F_K_

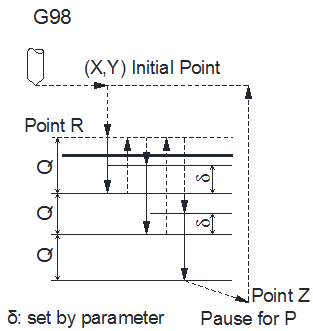

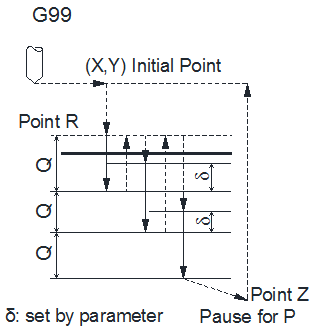

Machining Process

Machining process of G83 is as illustrated as follows:

- The tool moves to the specified hole position (X, Y) at G00 speed.

- The tool goes down to the specified point R at G00 speed.

- The tool moves down cutting depth Q relative to the present drilling depth at G01 speed.

- The tool moves up to the R point at G00 speed.

- The tool moves down until distance δ (specified by parameter “G73_G83 retract amount”) away from current drill depth at G00 speed.

- The tool moves down cutting depth Q relative to the present drilling depth at G01 speed.

- The tool moves up to the R point at G00 speed.

- The tool repeats above drilling operations until reaching point Z at the bottom of the hole.

- The tool returns to the initial point (G98) or point R (G99) at G00 speed.

Programming Example

F1200 S600

M03 'spindle CW on

G90

G00 X0 Y0 Z10 'move to the initial point

G17

G90 G99 'specify the coordinates of point R, point Z and hole 1, with cutting depth as 3.0, cutting speed as 800

G83 X5 Y5 Z-10 R-5 Q3 F800

X25 'hole 2

Y25 'hole 3

G98 X5 'hole 4, and set to return to the initial point

G80

M05 'spindle stops

M02