G84 Tapping Cycle

Format

G84 X_Y_Z_R_Q_F_K_

Machining Process

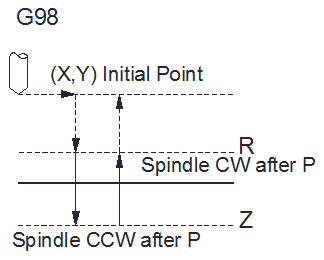

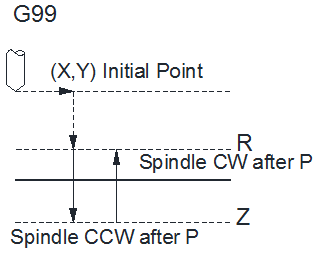

Machining process of G84 is as illustrated as follows:

- The tool moves to the specified hole position (X, Y) at G00 speed.

- The tool goes down to the specified point R at G00 speed.

- The tool moves down to point Z at the bottom of the hole at G01 speed.

- The tool pauses for P.

- The spindle rotates CW.

- The tool returns to point R at G01 speed.

- The tool pauses for P.

- The spindle rotates CW.

- The tool returns to the initial point (G98) or point R (G99) at G00 speed.

Programming Example

F1200 S600

G90

G00 X0 Y0 Z10 'move to the initial point

G17

M03 'spindle CW on

G90 G99 'specify the coordinates of point R, point Z and hole 1, with dwell as 2s, tapping speed as 800

G84 X5 Y5 Z-10 R-5 P2000 F800

X25 'hole 2

Y25 'hole 3

G98 X5 'hole 4, and set to return to the initial point

G80

M05 'spindle stops

M02