G86 High-speed Drilling Cycle

Format

G86 X_Y_Z_R_Q_P_F_K_

Machining Process

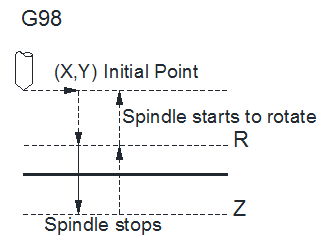

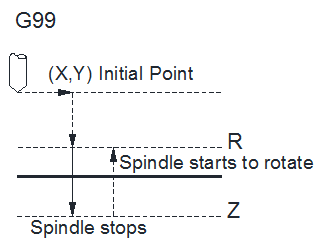

Machining process of G86 is as illustrated as follows:

- The tool moves to the specified hole position (X, Y) at G00 speed.

- The tool goes down to the specified point R at G00 speed.

- The tool moves down to point Z at the bottom of the hole at G01 speed.

- The spindle stops rotating.

- The tool returns to the initial point (G98) or point R (G99) at G00 speed.

- The spindle starts to rotate.

Programming Example

F1200 S600

G90

G00 X0 Y0 Z10 'move to the initial point

G17

M03 'spindle CW on

G90 G99 'specify the coordinates of point R, point Z and hole 1, with drilling speed as 800

G85 X5 Y5 Z-10 R-5 F800

X25 'hole 2

Y25 'hole 3

G98 X5 'hole 4, and set to return to initial point

G80

M05 'spindle stops

M02