Calibrate Capacitance

It is used to check the corresponding relationship of capacitance and position between the cutting head and the workpiece, so as to move Z-axis up and down in real time and make sure the relative distance between the cutting head and the workpiece is unchanged.

To calibrate capacitance, do the following:

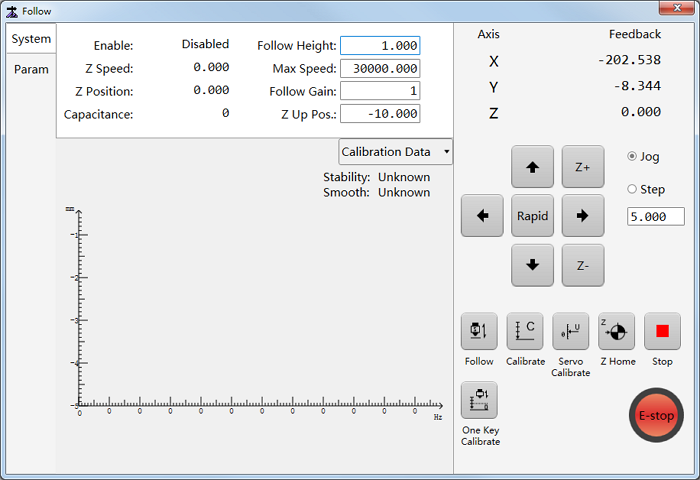

To open Follow dialog box, do one of the following:

In the common toolbar, click

Follow.

Follow.In the menu bar, click Advanced → Follow Control.

To eliminate zero drift caused by velocity loop controlling, click

Servo Calibrate. The cutting head slightly moves back and forth to compensate the error caused by zero drift.

Servo Calibrate. The cutting head slightly moves back and forth to compensate the error caused by zero drift.Select one of the following to move the cutting head to the position about 5mm far from the workpiece surface, and keep the workpiece still all the time:

If you have never calibrated capacitance, click the axis direction button, and click

Calibrate.

Calibrate.If you have calibrated capacitance before, click

One Key Calibrate.

One Key Calibrate.

The system starts to calibrate capacitance for 20s.

After calibrating capacitance, in Calibration Data area, check if levels of Stability and Smooth are above Good.

If they are below Good, please calibrate capacitance again.