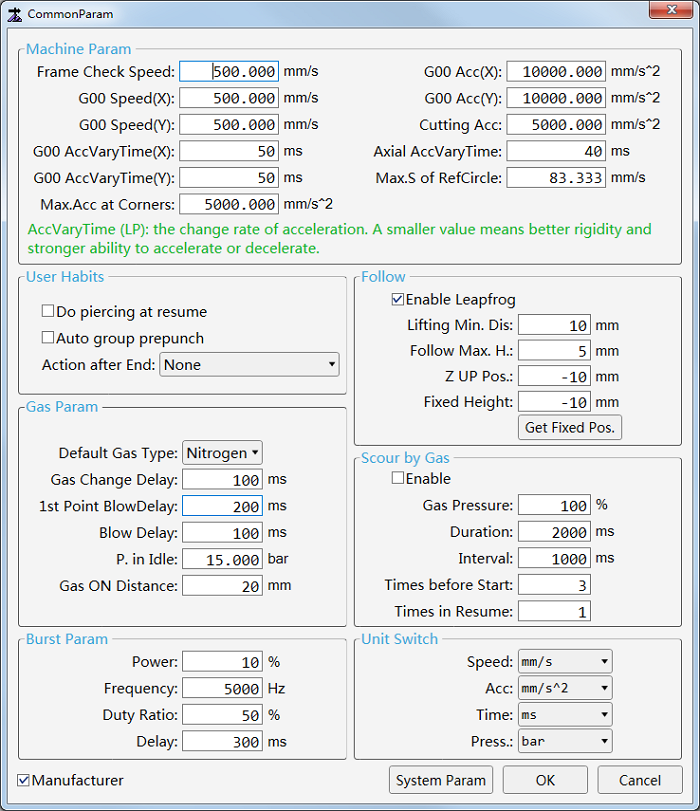

Set Common Parameters

It is used to set frequently used parameters, including machine parameters, gas parameters, burst parameters, following-up parameters, scouring parameters, set user habits and switch units.

To set common parameters, do the following:

To open Common Parameters dialog box, select one of the following:

In the common toolbar, click

CommonParam.

CommonParam.In the menu bar, click System → Common Parameters.

Set the following machine parameters in Machine Param area:

Frame Check Speed: the speed for framing cutting. Range: 0mm~60000.

G00 Speed: the G00 speed of each axis during machining. Range: 1mm~100000mm.

G00 AccVaryTime: the change time of G00 acceleration for a single axis. Range: 1mm~10000mm.

Max.Acc at Corners: the maximum acceleration of the adjacent axes. It is recommended to set it as 1~2 times of the maximum acceleration. Range: 0.1mm~50000mm.

G00 Acc: the maximum acceleration during G00 motion. Range: 0.001mm~50000mm.

Cutting Acc: the resultant acceleration in accelerating phrase during machining. Range: 0.1mm~50000mm.

Axial AccVaryTime: the change time of acceleration for a single axis during machining.

Max.S of RefCircle: the maximum speed for a reference circle with diameter 10mm. Range: 1mm~1000000mm.

Set the following user habits in User Habits area:

To do piercing at resume, check Do piercing at resume.

To automatically divide the objects with nested relation into the same group for pre-piercing, check Auto group prepunch.

To define X-axis and Y-axis action after machining, select in the drop-down box of Action after End.

Including no action, returning to the mark point, fixed point and workpiece origin.

Select the default gas type and set gas parameters in Gas Param area:

Gas Change Delay: mainly used for gradual piercing and segment piercing. If the gas for cutting is different from the gas for piercing, during the delay time for gas switching after piercing, laser will keep on.

1st Point BlowDelay: the delay time for blowing after the start of machining or breakpoint resume.

Blow Delay: the delay time for turn on blowing.

P. in Idle: the gas pressure for manual blowing in idle status.

Gas ON Distance: the maximum distance used for switch between two objects with the laser on.

Set the following burst parameters in Burst Param area:

Power: the laser intensity during burst.

Frequency: the carrier frequency of PWM modulate signals during burst.

Duty Ratio: in per unit pulse cycle, the ratio of light output time to the unit pulse cycle time during burst.

Delay: the duration for the laser on during burst.

Decide whether to enable leapfrog and set the following parameters in Follow area:

Leaping Min Dis: if the actual distance is less than the set value, leapfrog will not occur and the cutting head will traverse to the start point of next object without lifting.

Follow Max H.: if the cutting height / piercing height is less than the set value, the cutting head will follow to the set height. Otherwise, it will follow to 1mm position and lift to the set height.

Z UP Pos: the machine coordinate of Z-axis after turning off the height sensing unit after returning to the machine origin, or after machining ends.

Fixed Height: to fix Z-axis at the fixed height. During cutting at the fixed height, the height sensing unit will not turn on.

You can directly set its value or move the cutting head to the target position and click Get Fixed Pos.

Optional: To blow for cleaning the nozzle before cutting and make sure abundant gas in the channel for better cutting quality, enable scouring by gas and set the following parameters in Scour by Gas area:

Gas Pressure: the percent of gas pressure for scouring.

Duration: the duration for each scouring.

Interval: the interval between each scouring when the scouring times is greater than 1.

Times before Start: the scouring times when cutting starts.

Times in Resume: the scouring times during breakpoint resume.

Switch the unit of speed, acceleration, time or gas pressure in Unit switch area.

To switch to system parameters, click System Param at the bottom.