Set Scan Cutting

It is used to replan a toolpath to find the most efficient path to execute machining by controlling laser on/off, so as to avoid unnecessary tool lifting and feeding and improve machining efficiency.

It differs in the object type:

- Set scan cutting for lines.

- Set scan cutting for arcs.

- Set scan cutting for LED advertisement words.

- Set scan cutting for runways.

- Set scan cutting for sectors.

- Set scan cutting for rings.

Set Scan Cutting for Lines

To set scan cutting for lines, select the target objects, and do the following:

To open Line Scan pops up, do one of the following:

In the common toolbar, click

Scan.

Scan.In the common toolbar, click the drop-down box of

Scan, and select Line Scan.

Scan, and select Line Scan.In the menu bar, click Planning → Scan → Line Scan.

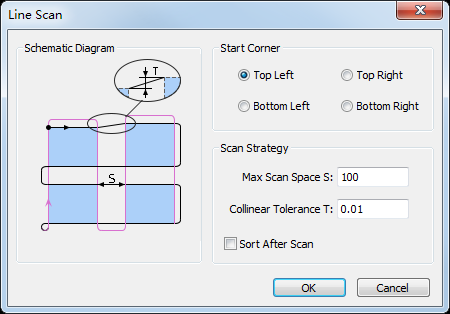

Select the start position for cutting, and set the following parameters:

Max Scan Space: if the distance between objects sharing a common edge is greater than the set value, objects will be divided into two groups to do scan cutting.

Colinear Tolerance: if the distance between two parallel lines in objects is less than the set value, the two lines will be regarded as a common edge.

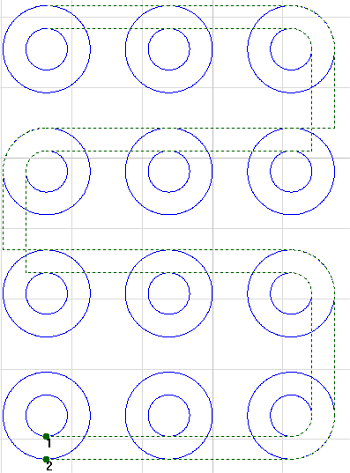

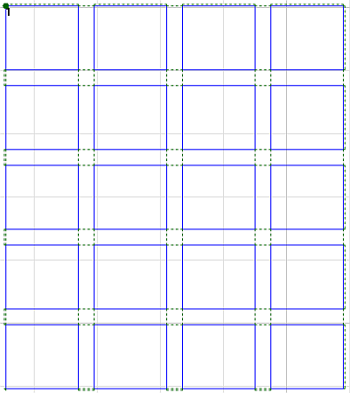

The result is as follows:

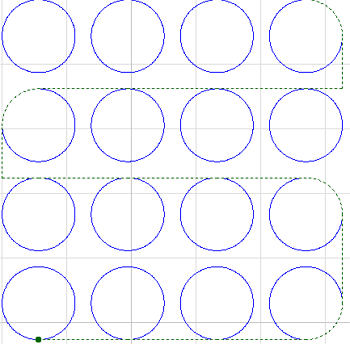

Set Scan Cutting for Circles

To set scan cutting for circles, select the target objects, and do the following:

To open Arc Scan dialog box, do one of the following:

In the common toolbar, click the drop-down box of

Scan, and select Arc Scan.

Scan, and select Arc Scan.In the menu bar, click Planning → Scan → Arc Scan.

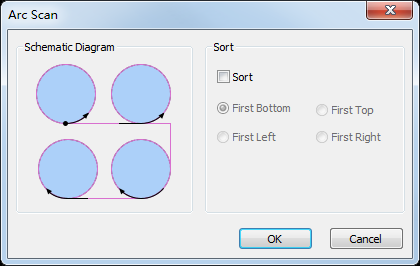

Optional: To select a sorting strategy, check Sort.

Default sorting strategy: Out -> In.

The result is as follows:

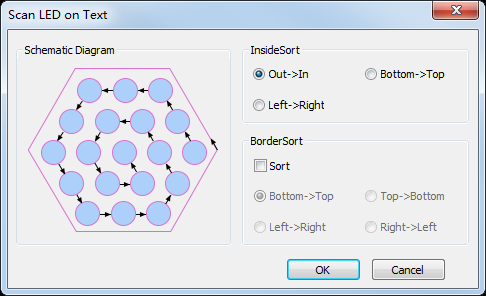

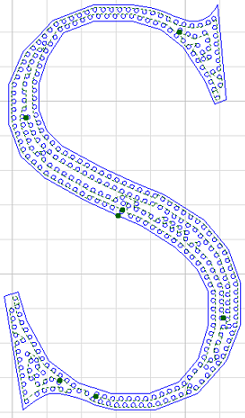

Set Scan Cutting for LED Advertisement Words

To set scan cutting for LED advertisement words, select the target objects, and do the following:

To open LED Scan dialog box, do one of the following:

In the common toolbar, click the drop-down box of

Scan → LED Scan.

Scan → LED Scan.In the menu bar, click Planning → Scan → LED Scan.

Set a sorting strategy:

Inside Sort: to sort all circles in the inner of the target objects, and form a scanning group.

Border Sort: to sort objects based on the frames of the target objects.

Taking sorting strategy Inside Sort as an example, the result is as follows:

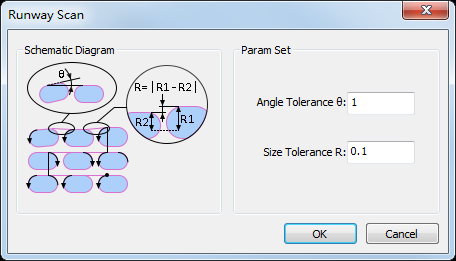

Set Scan Cutting for Runways

To set scan cutting for runways, select the target objects, and do the following:

To open Runway Scan dialog box, select one of the following:

In the common toolbar, click the drop-down box of

Scan → Runway Scan.

Scan → Runway Scan.In the menu bar, click Planning → Scan → Runway Scan.

Set the following parameters:

Angle Tolerance: if the angle difference is less than the set tolerance, the target objects are parallel. Range: 0°~5°.

Size Tolerance: if the height difference between two runways is less than the set tolerance, the sizes of target objects are the same. Range: 0mm~1mm.

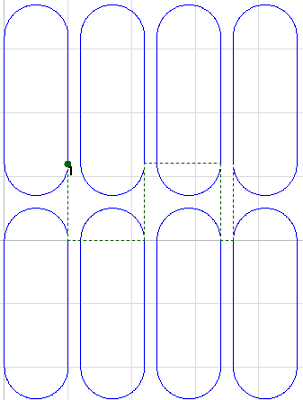

The result is as follows:

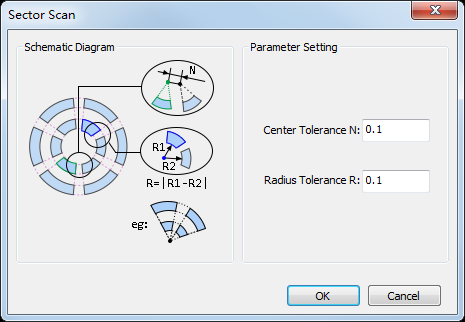

Set Scan Cutting for Sectors

To set scan cutting for sectors, select the target objects, and do the following:

To open Sector Scan dialog box, do one of the following:

In the common toolbar, click the drop-down box of

Scan → Sector Scan.

Scan → Sector Scan.In the menu bar, click Planning → Scan → Sector Scan.

Set the following parameters:

Center Tolerance: if the distance between circle centers of two circular rings is less than the set tolerance, the target objects are in a scanning group.

Radius Tolerance: if the radius difference between two circular rings is less than the set tolerance, the target objects are in a scanning group.

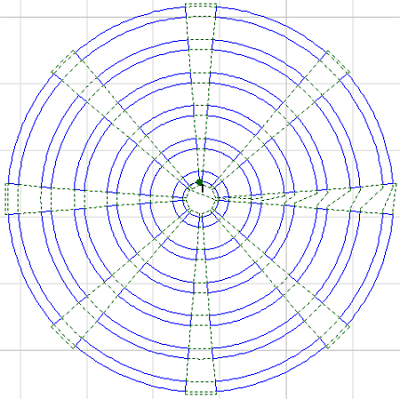

The result is as follows:

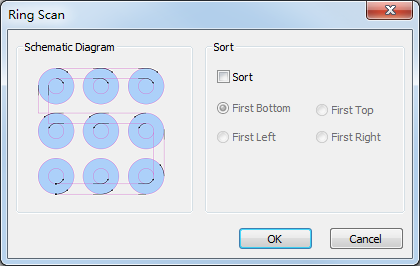

Set Scan Cutting for Rings

To set scan cutting for rings, do the following:

To open Ring Scan dialog box, do the following:

In the common toolbar, click the drop-down box of

Scan.

Scan.In the menu bar, click Planning → Scan → Ring Scan.

Optional: Check Sort and select the sorting direction.

The result is as follows: