Machine Origin

Definition

The machine origin, also known as the machine tool origin, is the origin of the machine coordinate system. Its position is generally set at the lower left/lower right position of the machine tool. It is a physical position set by the machine tool manufacturer on the machine tool. Its function is to synchronize the CNC machine tool with the control system and establish the start point for measuring the motion coordinate of the machine tool. Every time the CNC machine tool is started, the machine origin zero return operation must first be performed so that the CNC machine tool and the control system can establish a coordinate relationship and the control system can activate the soft limit function of each axis.

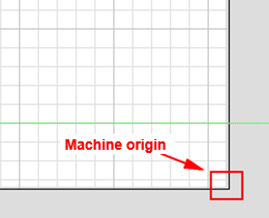

In the cutting software, taking the lower right corner as an example, the figure below shows the machine origin position displayed in the software.

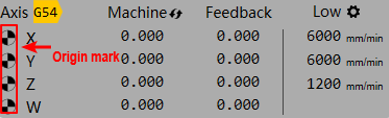

After the software successfully execute the machine origin zero return action, there will be an origin  mark (BMW mark) in the coordinate display column.

mark (BMW mark) in the coordinate display column.

There are two ways to set the machine origin return:

Datum setting

Machine zero return

Datum Setting

It is only applicable to absolute encoder machine tool. Using this method, there is no need to install a fixed origin signal on the machine tool.

Prerequisite:

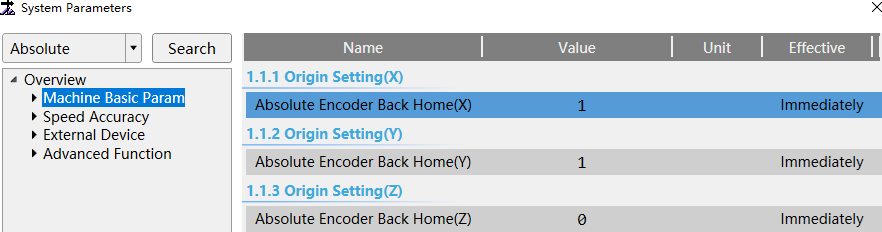

Before use, make sure the parameter Absolute Encoder Back Home(X) is set to 1.

Operation Steps:

Move cutting head to desired origin position.

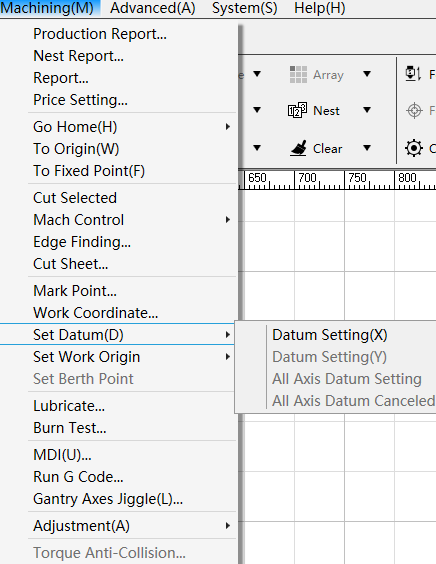

In the menu bar, click Machining → Set Datum and select the corresponding sub-menu to perform datum setting to set the current position as the machine origin position (datum point).

Machine Zero Return

It is suitable for incremental encoder machine tool and absolute encoder machine tool. When using this method to return to the mechanical origin, the machine tool must be equipped with a mechanical origin signal.

Prerequisite:

If it is an absolute encoder machine tool, before using this zero return method, the parameter Absolute Encoder Back Home(X) need to be set to 0.

Operation Steps:

If there is no BMW logo after opening the software, you can click Machining → Set Datum on the menu bar to select the corresponding axis to perform the return to machine origin operation.

Or operate on the machine tool control bar:

All Return to Machine Origin: Click

Go Home to automatically return to machine origin in the order of the Z-axis first, and then the X, Y, and W axes.

Go Home to automatically return to machine origin in the order of the Z-axis first, and then the X, Y, and W axes.Only Z-axis Return to Machine Origin: Click

.

.

Related Instructions:

The machine zero return method is divided into three steps: coarse positioning stage, fine positioning stage, and retract stage.

Coarse Positioning Stage: Find the origin switch according to the parameter coarse positioning stage direction and coarse positioning stage speed. After finding the origin switch, latch the coarse positioning stage axis feedback position;

Fine Positioning Stage: After the coarse positioning stage end, the fine positioning stage enter. Reversely search for the Z-phase signal according to the parameter fine positioning stage speed. After searching for the Z-phase signal, latch fine positioning stage axis feedback position;

If the Z-phase signal is not enabled for the corresponding axis, the signal detected by the fine positioning stage is still the machine origin signal.

Retract Stage: After the fine positioning stage is completed, retract to the target position according to the set retract distance and retract speed. It should be noted that when the retract distance parameter is positive, the retract direction is consistent with the coarse positioning direction. When the retract direction is negative, the retract direction and the coarse positioning direction are opposite. After retract is completed, the machine coordinate and feedback coordinate are set to 0, and there is a zero return mark in front of the corresponding axis.