Workpiece Zero Point

Definition

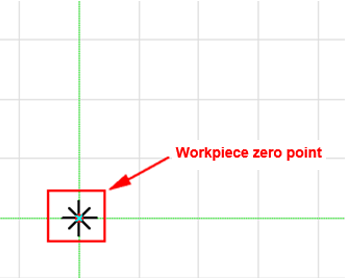

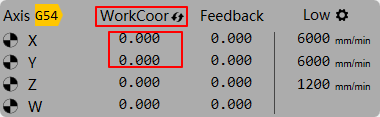

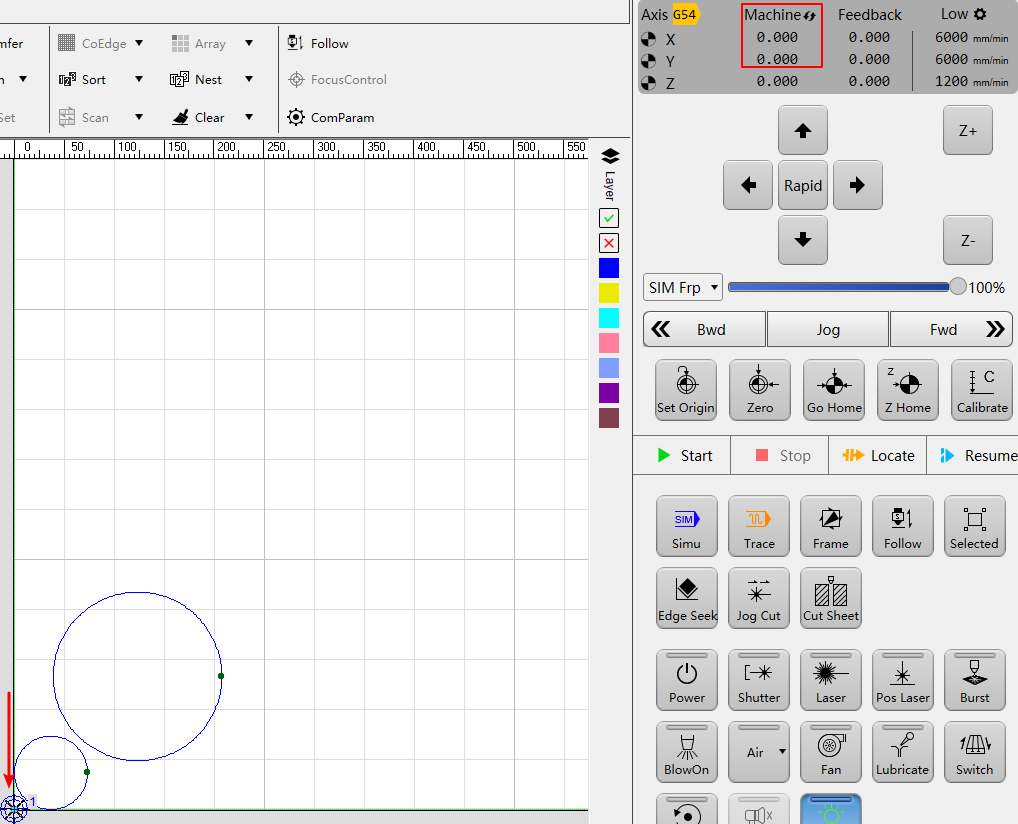

The workpiece zero point refer to the reference point used to determine the workpiece position and coordinate in machining. It is the start point during the machining process. In the cutting software, the intersection point of the two green coordinate lines in the coordinate system is the workpiece zero point, and the workpiece coordinate of the XY axis corresponding to the workpiece zero point is 0.

Set Workpiece Origin

The zero point of each axis in the tool path is the workpiece origin. Before machining, confirm the actual position of the workpiece origin on the plate.

Operation Steps:

Select any of the following methods to execute:

In the Drawing interface, drag the mouse to the cross mark at the intersection of the horizontal ruler and the vertical ruler to the target position.

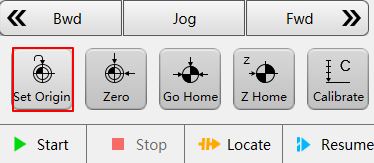

In the machine tool control bar, specify the laser head position as the workpiece origin:

a. Manually jog or step to move the cutting head to the target position.

b. Click

to set the current position as the workpiece origin.

to set the current position as the workpiece origin.Manually set the workpiece origin:

a. In the function menu bar, click

, and the cursor changes to

, and the cursor changes to  .

.b. Left click to select the workpiece origin position.

c. Right click to exit the picking tool.

Specify the coordinate of the laser head X-axis/Y-axis as the workpiece origin:

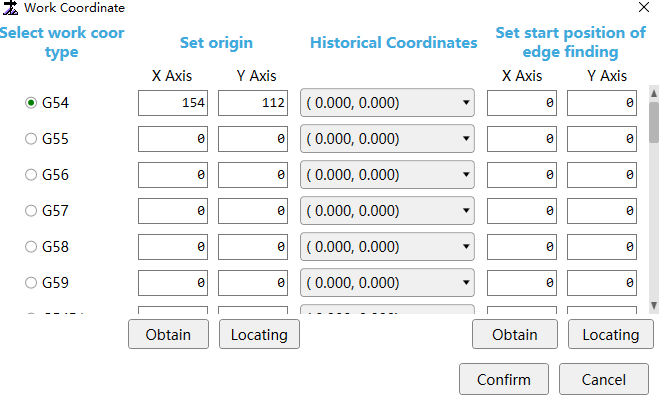

a. In the menu bar, click Machining → Work Coordinate.

b. Select coordinate system, set X/Y axis coordinate, or select historical workpiece origin.

c. Click Confirm. That is, the selected workpiece zero point is applied.

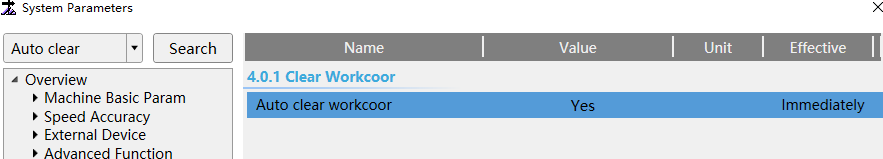

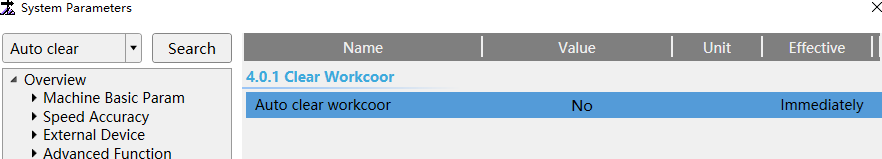

Auto Clear Workpiece Coordinate

To facilitate machining, you can set Auto Clear Workcoor to Yes in the system parameters. In this way, before machining start, directly move the cutting head to the desired workpiece zero point position, click Frame or Machining directly, and the current position will auto set to the workpiece zero point.

When the system parameter Auto Clear Workcoor is set to No, manual workpiece to zero is needed.

Manual workpiece to zero method: First move the cutting head to a suitable position on the plate (generally recommended in the lower left corner), and then click the Set Origin button.

At this time, the workpiece coordinate of the XY axis return to 0, and the workpiece zero coordinate datum on the software will move to the cross cursor position.

Workpiece Zero Return

Operation Steps:

Manual control: In the machine tool control bar, click

and the cutting head will move to the workpiece zero position.

and the cutting head will move to the workpiece zero position.After machining, auto return to the workpiece origin:

Click System → System Parameters in the menu bar and set the value of the parameter Additional Behavior of XY Axes after Machining to 10.