Seal

A seal is formed between the cutting start point and the end point of the part, and the seal method is divided into gap and overcut.

Gap: It means to keep a certain distance between the start point and the end point, which is used for the adhesion of parts and plates, and can prevent parts from warping after cutting.

Overcut: It means that the end point continues to cut forward for a certain distance after passing the start point, the purpose is to remove the possible start point slag.

Set Gap

Operation Steps:

Select one or more graphics.

In the common toolbar, click

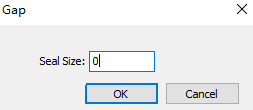

drop down → Gap to open the Gap dialog box:

drop down → Gap to open the Gap dialog box:

Sets the length of gap.

Click OK.

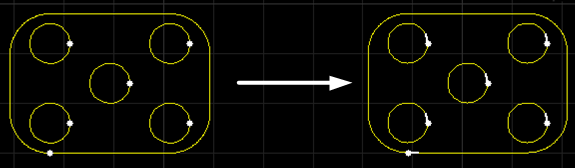

Add gap effect diagram:

Set Overcut

Operation Steps:

Select one or more graphics.

In the common toolbar, click

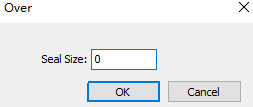

drop down → Overcut to open the Over dialog box:

drop down → Overcut to open the Over dialog box:

Sets the length of the overcut.

Click OK.

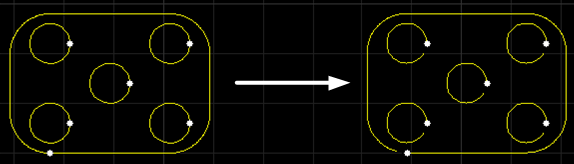

Add overcut effect diagram: