Basic Editing

It is used to edit drawn and imported objects, so as to modify the toolpath according to the requirement.

It includes the following:

- Translate objects

- Rotate an object

- Mirror an object

- Align objects

- Scale objects

- Merge objects

- Share an edge

- Explode objects

- Break objects

- Execute rectangular array

- Execute tube array

- Set tube intersection

- Set tube cutting

- Set vertical intersection

- Set inner diameter first

- Set weld compensation

Translate Objects

It is used to move objects a certain distance. As a result, coordinate of objects will be changed without changing the size of objects.

During translating objects, the system will automatically catch the center line.

To translate objects, select the target objects and do the following:

Press the left mouse button and drag the objects.

On the keyboard, press ↑ / ↓ / ← / →.

Call Translate command:

Click

Transf → Translate in the common tool bar, or click Edit → Translate in the menu bar.

Transf → Translate in the common tool bar, or click Edit → Translate in the menu bar.Left click on the drawing window.

Move the cursor to the target position and click again.

Rotate an Object

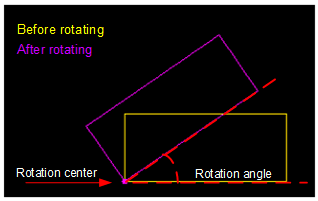

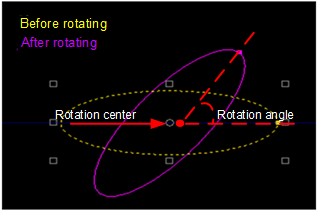

It is used to move or turn an object around a certain fixed point, so as to change the position and direction of the object.

To rotate an object, select the target object, and do one of the following:

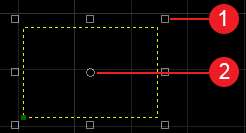

Press Ctrl, and rotate a rectangular point around the object.

The rotation center is the center of the external rectangle by default. It is shown as a circle. You can drag the circle to change the rotation center.

- Rectangular point

- Rotation center

In the common tool bar, enter the rotation angle in Angle input box and press Enter.

If the object is a rectangle or text, the lower left point of the object is the rotation center.

If the object is a star, polygon or ellipse, the center point of the object is the rotation center.

Call Rotate command:

In the common tool bar, click

Transf→ Rotate, or click Edit → Rotate.

Transf→ Rotate, or click Edit → Rotate.Left click to select the rotation center.

Move the cursor to adjust the rotation angle.

Left click to confirm.

Mirror an Object

It includes the following:

Vertical mirror: mirror along X-axis with the center of the object as the center of rotation.

Horizontal mirror: mirror along Y-axis with the center of the object as the center of rotation.

To mirror an object, select an object, and do one of the following:

In the common tool bar, click

Transf → Vertical Mirror / Horizontal Mirror.

Transf → Vertical Mirror / Horizontal Mirror.In the menu bar, click Edit → Mirror → Vertical Mirror / Horizontal Mirror.

Align Objects

It is used to arrange the objects in a straight line.

To align objects, select several objects, in the menu bar, click Edit → Align , and select one of the following:

- Align Left

- Align Right

- Align Top

- Align Bottom

- Align Center Point

- Align Horizontally

- Align Vertically

- Distribute Horizontally

- Distribute Vertically

The system automatically aligns objects.

Scale Objects

It is used to make objects appear larger/smaller in equal proportion.

To scale objects, select the target objects, and do the following:

In the common tool bar, enter the scaling factor in Scale input box and press Enter.

In the menu bar, call Scale command:

Click Edit → Scale.

Left click to select the center point for scaling.

Move the cursor to adjust the scaling factor.

Left click to confirm.

Merge Objects

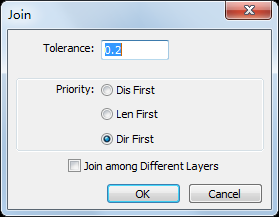

It is used to combine unclosed objects within the set tolerance, so as to help to avoid unnecessary tool lifting and improve machining efficiency.

Tolerance is the allowable distance between objects that need to be combined.

The objects cannot be the following:

- Closed objects

- Dot

- Text

Before merging objects, it is suggested to enable catch options.

To merge objects, select the target objects, and do the following:

To open Join dialog box, do one of the following:

In the common tool bar, click

Merge.

Merge.In the menu bar, click Edit → Merge.

Right click on the drawing window and select Merge.

Set Tolerance between 0.01mm and 10mm.

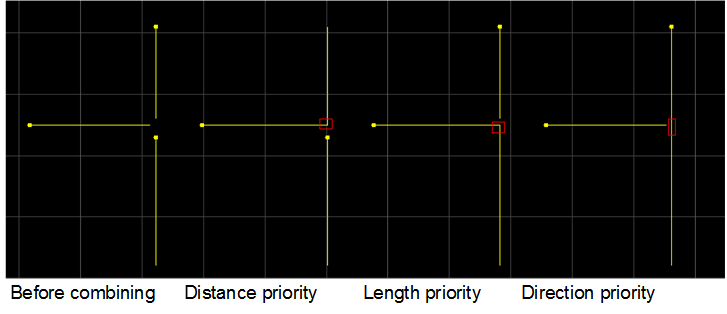

Select Priority to decide the standard for combining. If there exist more than two end points can be combined, the system combines objects that are nearest / longest / in the same direction.

Optional: Check Merge among different layers. The system merges objects of different layers into the object within higher layer order.

The result is as follows:

Share an Edge

It is used to make the overlapped edges become a shared edge, so as to avoid cutting the same edge during machining, and optimize the toolpath.

The error for sharing an edge is 0.1mm.

The objects that can share an edge should meet the following demands:

- The target number of objects should be greater than 2.

- The target objects should be intersection lines.

To share an edge, select the target intersection lines, and do the following:

Click Planning → Common Edge.

Right click on the drawing window, and click Common Edge.

In the Tube Array dialog box, check Common edge.

See Execute Tube Array for details.

The system automatically only keeps an intersection line.

Explode Objects

It is used to delete extra lines, so as to trim the toolpath. It usually applies to polyline.

It is suggested to use it together with merging function, to correct mistakes by drawing and ensure machining quality.

If the object is text, exploding objects equals to turning the text into polylines.

To explode objects, select the target objects, and do one of the following:

In the common tool bar, click

Explode.

Explode.In the menu bar, click Edit → Explode.

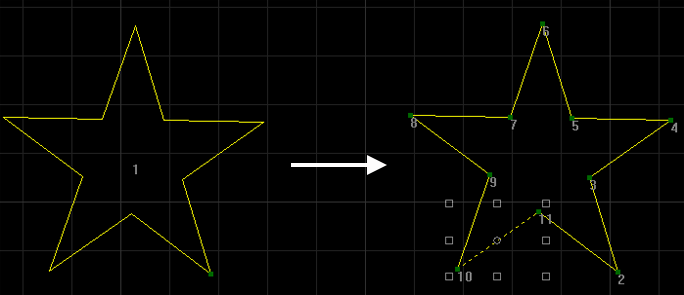

The result is as follows:

Break Objects

It is used to cut objects into several polylines.

It is usually used in the following situation:

Connect the cutting part to surrounding material. It equals to micro joint.

Cut extra objects during drawing objects.

To break objects, do one of the following:

To break all the selected objects at the same time, automatically break objects.

To break one object each time by freely selecting where to break, manually break an object.

Automatically Break Objects

To automatically break objects, select the target objects, and do the following:

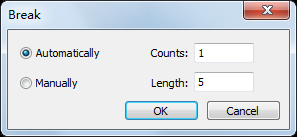

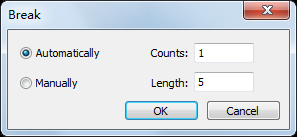

In the menu bar, click Edit → Break. Break dialog box pops up:

Select Automatically and enter the number and distance of breaking lines.

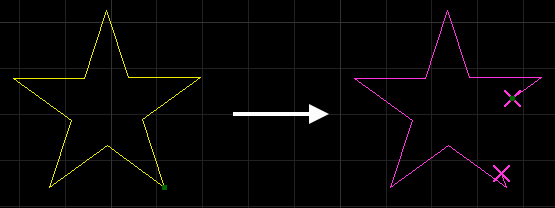

The result is as follows:

Manually Break an Object

To manually break an object, do the following:

In the menu bar, click Edit → Break. Break dialog box pops up:

Select Manually and enter the distance of breaking lines.

Click OK. The cursor turns to

.

.Left click to select the positions for breaking.

Right click to finish breaking.

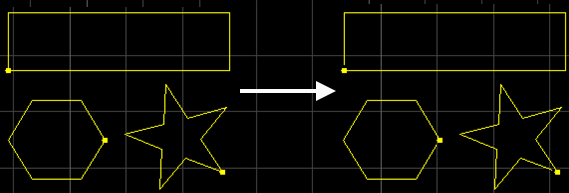

The result is as follows:

Execute Rectangular Array

It is used to copy the machining objects and arrange them in a rectangular array, so as to improve machining efficiency.

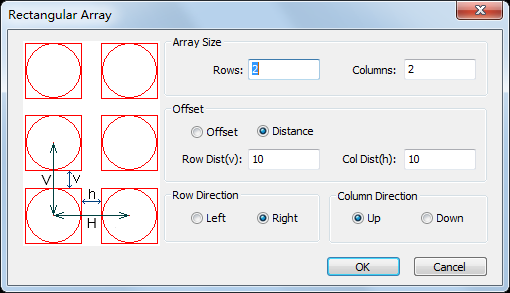

To execute rectangular array, select the target objects, and do the following:

To open Rectangular Array dialog boa, do one of the following:

In the common tool bar, click

Rect Array.

Rect Array.In the menu bar, click Drawing → Rect Array.

Set the number of rows and columns for array.

In Offset area, select one of the following ways:

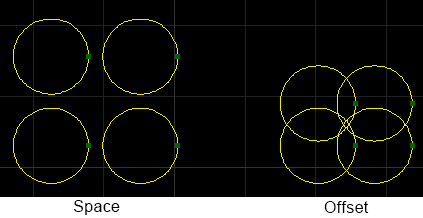

Offset: based on the center of the object.

Space: based on the frame of the objects.

Select the direction for rows and columns.

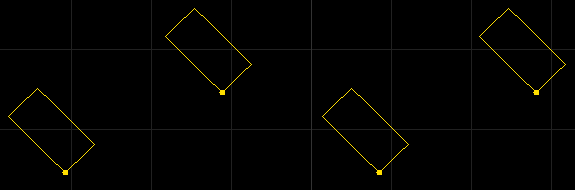

After executing rectangular array, the result automatically shows in the drawing window. Taking Offset as an example, the result is as follows:

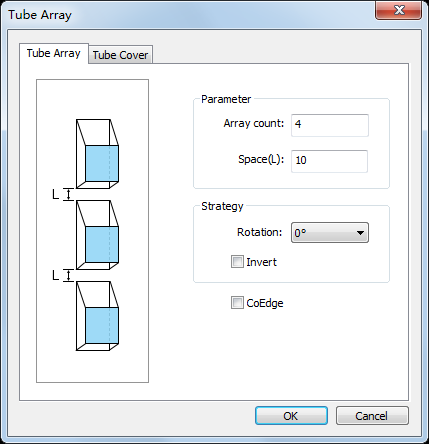

Execute Tube Array

There is usually only one tube on the toolpath file. This operation is used to copy the tube according to the rotation strategy.

To execute tube array, select the target object, and do the following:

Select the part containing two intersection lines.

To open Tube Array dialog box, do one of the following:

In the common tool bar, click

Tube Array.

Tube Array.In the menu bar, click Nest → Tube Array.

Right click on the drawing window, and click Tube Array.

Select an array method:

Tube Array: arrange the objects in order according to the array count and intersection lines.

Tube Cover: arrange the objects in order according to the length of the tube and intersection lines.

Set the count of array or the tube length and array space.

Select a rotation strategy:

Select 0°. The tube does not rotate and only translates the array in Y-axis direction.

Select 0° and check Invert. The tube rotates 180° in X-axis direction. That is, the current face rotates 180°.

Select 180° and check Invert. The tube rotates 180° in Y-axis direction.

You can preview the diagram on the left.

Optional: If the intersection line that can be regarded as the same object within an allowable error, to reduce overlapped edge, check Common Edge.

If parameter Space is set to 0, it is suggested to check Common Edge for intersection lines.

See Share an Edge for details.

After executing tube array, the result automatically shows in the drawing window.

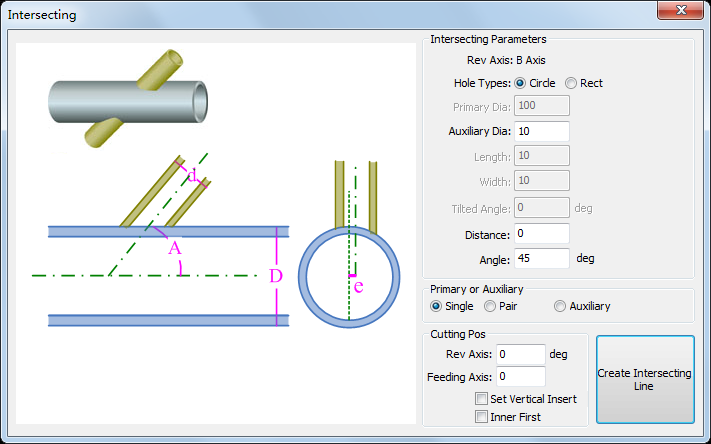

Set Tube Intersection

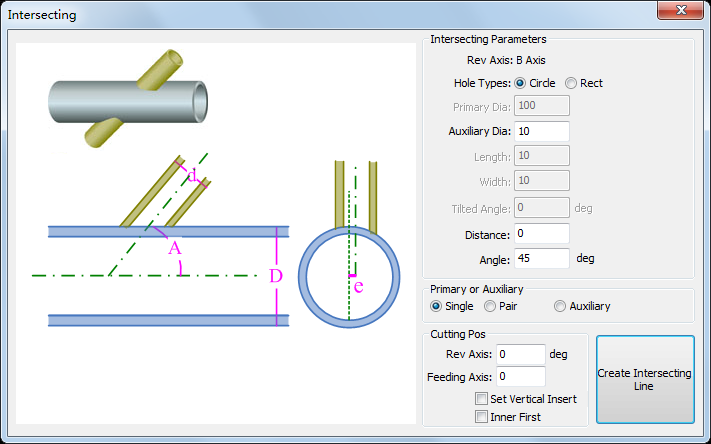

It is used to generate insert a circular tube or a rectangular tube (auxiliary tube) into another circular tube or a rectangular tube (primary tube) and generate a circular hole or a rectangular hole.

Taking circular tube intersection as an example, to set tube intersection, do the following:

To open Intersecting dialog box, do one of the following:

In the drawing tool bar, click

.

.In the menu bar, click Technics → Intersecting.

Select a hole type according to the shape of the tube and set intersection parameters:

Circle: generate a single hole or two holes on the primary tube. Or cut the end of the auxiliary tube according to the shape of the hole on the primary tube.

Rect: only generate a single rectangular hole.

See Related Parameters for details.

In area Cutting Pos, set the following parameters:

Rev Axis: the angle between the cutting objects and the workpiece origin.

Feeding Axis: the vertical distance between the cutting objects and the workpiece origin.

Optional: To enable vertical intersection, check Set Vertical Insert.

See Set Vertical Intersection for details.

Optional: To enable inner diameter first, check Inner First.

See Set Inner Diameter First for details.

Click Create Intersecting Line.

Optional: To cut several intersection holes on a circular tube, repeat step 3 and click Create Intersecting Line.

The result is as follows:

Cutting a single hole on the primary tube

Cutting a pair of holes on the primary tube

Cutting the end of the auxiliary tube according to the shape of the hole on the primary tube

Yellow line: without inner first; blue line: with inner first.

Cutting several circular holes on the primary tube

Cutting several rectangular holes on the primary tube

Related Parameters

Rev Axis: In the rotary table configuration, rotary axis is fixed.

Primary Dia: The diameter of the primary tube. If you select Single or Pair cutting hole type, it is fixed in Tube Cutting Setting.

Auxiliary Dia: The diameter of the auxiliary tube. It should be greater than that of the primary tube. If you select Auxiliary cutting hole type, it is fixed in Tube Cutting Setting.

Distance: The distance between the central line of the primary tube and the central line of the auxiliary tube. Its maximum distance should meet ± (Primary diameter - Auxiliary diameter) / 2.

Angle: The intersection angle between the primary tube and the auxiliary tube. Range: 5°~175°

Set Tube Cutting

It is used to cut a tube and generate cutting toolpath on the tube.

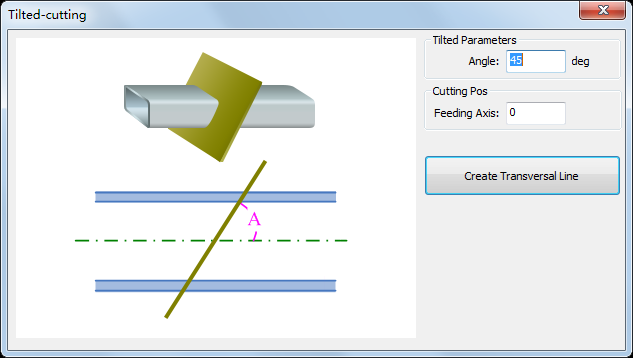

Taking tube cutting for a rectangular tube, to set tube cutting, do the following:

In the drawing tool bar, click

. Tilted Cutting dialog box pops up:

. Tilted Cutting dialog box pops up:

Set the following parameters:

Angle: The angle between the cutting face and the central line of the tube. Range:5º~175º

Feeding Axis: The coordinate of the feeding axis on the tube.

Click Create Transversal Line.

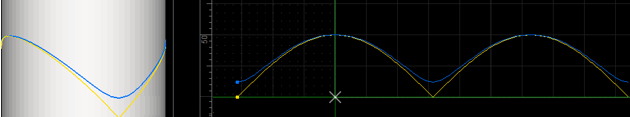

Set Vertical Intersection

Generally, the outer cutting hole may be larger than inner cutting hole caused by intersection cutting. This operation is used to ensure the sizes of outer and inner cutting holes are the same.

Before setting vertical intersection, ensure the following:

- The tube type belongs to rectangular tube, circular tube, oval tube or waist tube.

- The diameter of the auxiliary tube is not greater than the half of the diameter of the primary tube.

- The target object is not a dot, text, scanning group and the object covering over the half of a tube.

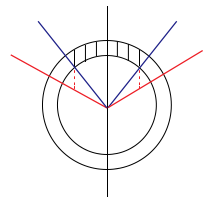

The track for vertical intersection is as follows:

To set vertical intersection, do one of the following:

Set vertical intersection in the drawing window:

Select the target objects.

Right click on the drawing window, click Set Vertical Insert. After setting, the selected objects turn into white.

Set vertical intersection for a circular tube in Intersecting dialog box:

To open Intersecting dialog box, click

in the drawing tool bar, or click Technics → Intersecting in the menu bar.

in the drawing tool bar, or click Technics → Intersecting in the menu bar.

To enable vertical intersection, in Cutting Pos area, check Set Vertical Insert.

Click Create Intersecting Line.

The system generates and loads the cutting toolpath automatically.

If you need to cancel the setting of vertical intersection, select the objects, right click and select Clear → Vertical Insect.

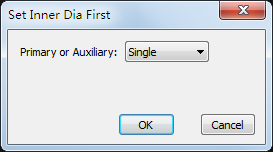

Set Inner Diameter First

The cutting track for inner diameter first is as follows (purple: without inner diameter first; red: with inner diameter first):

To set inner diameter first, do the following:

In the menu bar, click Technics → Set Inner Dia First. Set Inner Dia First dialog box:

Select a cutting method:

Single

Pair: setting the angle is required.

Set Weld Compensation

It is used to compensate the welding seam caused by welding. It is only available for circular tubes and rectangular tubes.

In the menu bar, to set weld compensation, click Technics → Weld Compensation → All / Selected.