Operations

It is used to specify a layer and set related parameters for the layer.

To do layer related operations, do the following:

Select the target objects, click the target layer color in the main interface. The selected objects turn into the target color.

To open Layer Setting dialog box, do one of the following:

In the layer tool bar, click

Layer.

Layer.In the menu bar, click Technics → Layer Setting.

For Layer Setting dialog box, see Overview for details.

After doing layer related operations, add technic remarks.

Set Technic Parameters

To set technic parameters, do the following:

To switch to layer n-Technic Param interface, click layer n-Technic Param:

Set parameters in Technic Param and Special Technic areas.

See Technic Parameters for parameter details.

Edit the Power Curve

It is used to make the cutting power and frequency change with the cutting speed accordingly and ensure thermal power absorbed in unit area is the same and achieve fine cutting result, so as to solve problems like over-burning around the corner and difference of cutting result in terms of thickness.

The more the nodes you add, the more precise the curve is.

Before editing the power curve, in the Power Curve area, do the following according to your need:

Check Enable Speed Power Adjust. The system makes the cutting power change with the cutting speed during cutting.

Otherwise, the cutting power keeps the same all the time during cutting.

Check Enable Speed Freq. Adjust. The system makes the cutting frequency change with the cutting speed during cutting.

Otherwise, the cutting frequency keeps the same all the time during cutting.

Taking checking Enable Speed Power Adjust as an example, to edit the power curve, do the following:

Click Edit. Speed Power Curve Editing dialog box pops up:

To modify the node, do one of the following:

On the curve

To add a node, double click the target position.

To delete a node, double click the target node.

The corresponding speed and power nodes are added / deleted in the right list synchronously.

In the list

- To add a group of speed and power nodes, click Add, and double click to modify the values.

To delete a group of speed and power nodes, select the values and click Delete.

The corresponding speed and power nodes are added/deleted on the left curve synchronously.

To restore the curve to default, click Clear.

Import and save as a Technic File

To import and save as a technic file, in Technic File Operation area, do one of the following:

To import a technic file, click Import and select the target technic file in Import dialog box:

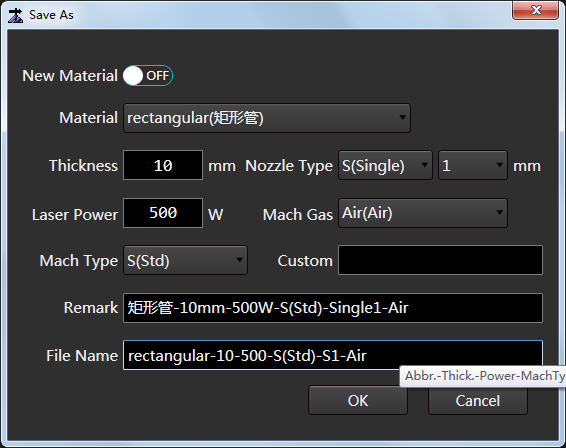

To save the technic as a file, click Save As, and set related parameters in Save As dialog box:

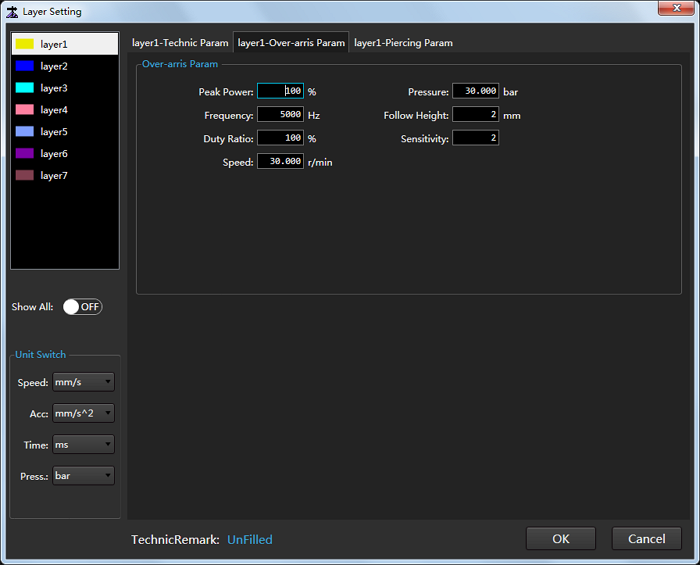

Set Over-arris Parameters

To set over-arris parameter, do the following:

To switch to layer n-Over-arris Param page, click layer n-Over-arris Param:

In Over-arris Param area of layer n-Over-arris Param page, set over-arris parameters.

See Over-arris Parameters for parameter details.

Set Piercing Parameters

To set piercing parameters, do the following:

To switch to layer n-Piercing Param page, click layer n-Piercing Param:

Select a piercing method.

See Piercing Methods for details.

Set related piercing parameters.

See Piercing Parameters for parameter details.

Optional: Check Increment S and set the parameter.

It is the speed of the cutting head during falling to the cutting height.

If it is unchecked, the cutting head follows to cutting height.

Note: In 3rd segment piercing, with Increment S checked, the system does increment piercing. Otherwise, it does segment piercing.

Optional: To make the system turns off the later and execute blowing after piercing, check Extra Blow, and set parameter Delay and Pressure.

Otherwise, the system executes blowing with laser on after piercing.

To add remarks, in Remarks area, input the remarks.

Add Technic Remarks

It is used to set technic remarks, and it is convenient for the system to automatically generate the name of a technic file during saving or saving as the technic file.

To add technic remarks, do the following:

In Layer Setting dialog box, in the technic remark area, click the characters in blue after character TechnicRemark. Set Technic Remark dialog box pops up:

Set the tube type and thickness, nozzle type, laser power, machining gas, machining type and customized item.