Execute Micro Joint

It is used to connect the cutting part with surrounding material without falling down the material. By doing this, you can avoid the problem that the part becomes warped and collides with the cutting head moving at high speed, because the cutting part can neither fall from the gap of supporting rods nor be held by the supporting rods.

To execute micro joint, do one of the following:

Automatically Execute Micro Joint

To automatically execute micro joint, do the following:

To open Micro Joint dialog box, do one of the following:

In the common toolbar, click

Micro Joint.

Micro Joint.In the menu bar, click Technics → Micro Joint.

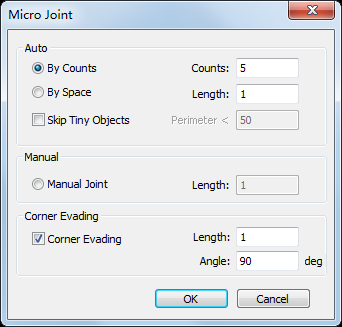

In Auto area, select a strategy for micro joint and set related parameters.

Optional: To ignore tiny objects within a value during executing micro joint, check Skip Tiny Objects and set parameter Perimeter.

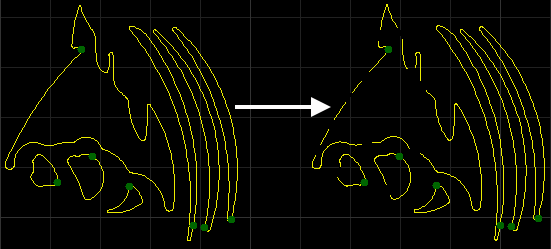

Taking selecting strategy By Counts and setting parameter Counts to 5 as an example, the result is as follows:

Manually Execute Micro Joint

To manually execute micro joint, do the following:

To open Micro Joint dialog box, do one of the following:

In the common toolbar, click

Micro Joint.

Micro Joint.In the menu bar, click Technics → Micro Joint.

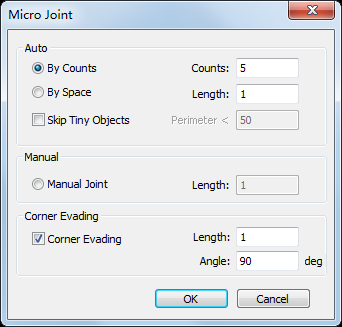

In Manual area, select Manual Joint, and set parameter Length.

Click OK. The cursor turns to

.

.To select a position for micro joint, left click.

After manually executing micro joint, to exit Micro Joint command, right click.

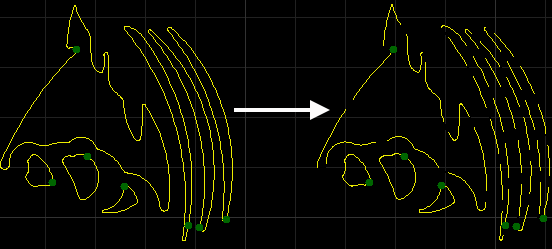

The result is as follows: