Set Scan Cutting

It is used to replan a toolpath to find the most efficient path to execute machining by controlling laser on/off, so as to avoid unnecessary tool lifting and feeding and improve machining efficiency.

It differs in the object type:

- Set scan cutting for lines.

- Set scan cutting for circles.

- Set scan cutting for LED advertisement text.

Set Scan Cutting for Lines

To set scan cutting for lines, select the target objects, and do the following:

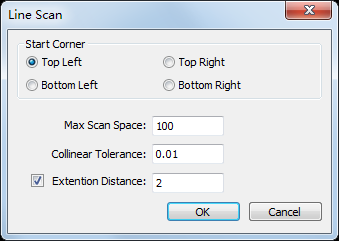

To open Line Scan pops up, do one of the following:

In the common tool bar, click

Scan.

Scan.In the common tool bar, click the drop-down box of

Scan, and select Line Scan.

Scan, and select Line Scan.In the menu bar, click Planning → Scan → Line Scan.

Select the start position for cutting, and set parameter Colinear Tolerance and Max Scan Space.

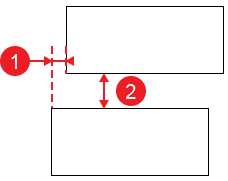

①: Collinear Tolerance; ②: Max Scan Space.

Optional: Check Extension Distance and set a value.

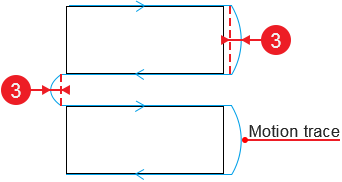

③: Extension Distance

The result is as follows:

Set Scan Cutting for Circles

To set scan cutting for circles, select the target objects, and do the following

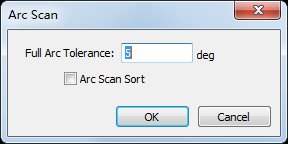

To open Arc Scan dialog box, do one of the following:

In the common tool bar, click the drop-down box of

Scan, and select Arc Scan.

Scan, and select Arc Scan.In the menu bar, click Planning → Scan → Arc Scan.

Set parameter Full Arc Tolerance.

Optional: To sort the selected circles by the default array sorting strategy, check Arc Scan Sort.

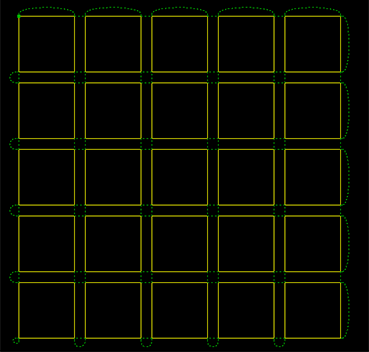

The result is as follows:

Set Scan Cutting for LED Advertisement Text

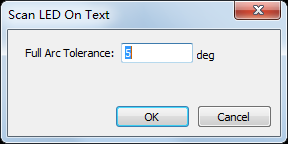

To set scan cutting for LED advertisement text, select the target objects, and do the following:

To open LED Scan dialog box, do one of the following:

In the common tool bar, click the drop-down box of

Scan → LED Scan.

Scan → LED Scan.In the menu bar, click Planning → Scan → LED Scan.

Set parameter Full Arc Tolerance.

The result is as follows: