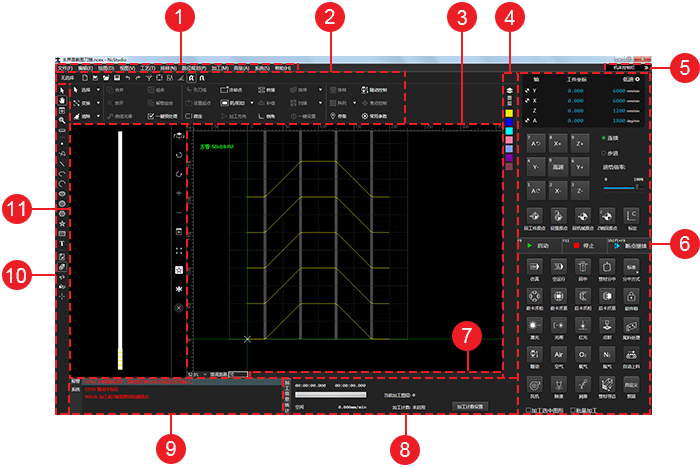

Main Interface

Through this part, you can quickly know the layout of the main interface for NcStudio V15 Laser Cutting (Tube) CNC System.

- Menu bar

- Common tool bar

- Drawing window

- Layer tool bar

- Window display button

- Machine control area

- Status area

- Statistics area

- Alarm/system info area

- Drawing tool bar

- 3D view area

Common Tool Bar

It is used to show the following frequently used instructions:

: New

: NewUsed to create a new toolpath file by selecting a kind of tube type and setting parameters for the section.

: Import

: ImportUsed to import an

IGS/IGESfile. : Open

: OpenUsed to open a

NCEXfile. : Save

: SaveUsed to save a toolpath file.

A new file is saved as a

NCEXfile. : Undo

: UndoUsed to go back to a previous state.

: Redo

: RedoUsed to recover canceled operations.

: Show order

: Show orderUsed to show or hide the machining order.

: Show direction

: Show directionUsed to show or hide the machining direction.

: Highlight unclosed objects

: Highlight unclosed objectsUsed to mark all unclosed objects with red color.

: Clear trace

: Clear traceUsed to clear the machining trace.

: Catch

: CatchUsed to enable/disable catching function.

: Catch options

: Catch optionsUsed to open Catch Options dialog box and set options for catching.

: Select

: SelectUsed to select unclosed objects, tiny objects, inner objects, outer objects, similar objects. See Select Objects for details.

: Transform

: TransformUsed to translate objects, rotate objects, mirror objects vertically or horizontally. See Translate Objects and Rotate an Object for details.

: Clear

: ClearUsed to clear some set technics. See Do Clearing for details.

: Merge

: MergeUsed to open Combine dialog box and combine objects. See Merge Objects for details.

: Explode

: ExplodeUsed to trim the toolpath. See Explode Objects for details.

: Smooth curve

: Smooth curveUsed to make polylines flat and even. See Smooth Curves for details.

: Preprocess

: PreprocessUsed to open Instant Pre-process dialog box when several target objects are selected and preprocess objects with one click. See Preprocess with One Click for details.

: Lead line

: Lead lineUsed to open Set dialog box and set a lead line. See Set a Lead Line for details.

: Start point

: Start point- With a lead line: used to set the start point of the lead line.

- With no lead line: used to set the current point as the start point.

: Micro joint

: Micro jointUsed to open Micro Joint dialog box and set related parameters. See Execute Micro Joint for details.

: Cool point

: Cool pointUsed to open Cooling Point dialog box and add cooling points. See Add Cooling Points for details.

: Unfill / fill

: Unfill / fillUsed to set fill or unfill. See Set Fill or Unfill for details.

: Mach direction

: Mach directionUsed to open Set Machining Direction dialog box and set machining direction. See Change the Machining Direction for details.

: Bridge

: BridgeUsed to open Bridge dialog box and bridge objects. See Bridge Objects for details.

: Compensate

: CompensateUsed to open Kerf Compensation dialog box and compensate the kerf. See Compensate the Kerf for details.

: Chamfer

: ChamferUsed to open Chamfer dialog box and add chamfers. See Add Chamfer.

: Sort machining order

: Sort machining orderUsed to set the machining order. See Change the Machining Order for details.

: Scan cut

: Scan cutUsed to replan the toolpath to find the most efficient path for machining, so as to avoid unnecessary tool lifting and feeding and improve machining efficiency. See Set Scan Cutting for details.

: Instant setting

: Instant settingUsed to set fill/unfill, lead line, machining direction, machining order and kerf compensation with one click. See Execute Instant Setting for details.

: Tube array

: Tube arrayUse to nest objects. See Execute Tube Array for details.

: Rectangular array

: Rectangular arrayUse to execute rectangular array. See Execute Rectangular Array for details.

: Follow-up

: Follow-upUsed to open Follow-up Control dialog box. See Calibrate Capacitance for details.

: Control focus

: Control focusUsed to open Focus Control dialog box. See Control the Focus for details.

: Common Param

: Common ParamUsed to open Common Param dialog box, set frequently used machine parameters, user habit, gas parameters, burst parameters, and switch unit.

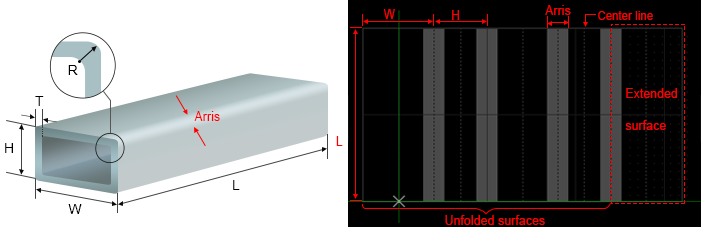

Drawing Window

It is used to draw and preview objects.

In tube cutting configuration, the development effect of a rectangular tube shows in drawing window for ease of drawing:

Length of an arris: depending on the corner radius and thickness of the rectangular tube.

Extended face: corresponding to the first face of the actual tube.

Center line: including face center line and arris center line. It exists on each face. When you drag the object, the center of the object automatically gets close to the center line.

Layer Tool Bar

It is used to do operations related to layer.

It includes the following:

See Layer Interface for details.

Window Display Button

It is used to show/hide the machine control area.

See Machine Control Area for details.

Machine Control Area

It includes the following:

Axis Coordinate Display Area

It is shown as follows:

After returning to the machine origin, sign  appears in front of each axis.

appears in front of each axis.

In this area, you can do the following:

To switch among workpiece coordinates, machine coordinates and feedback coordinates, do one of the following:

Double click Work/Machine/Feedback.

Move the cursor to character Work/Machine/Feedback, and click

.

.

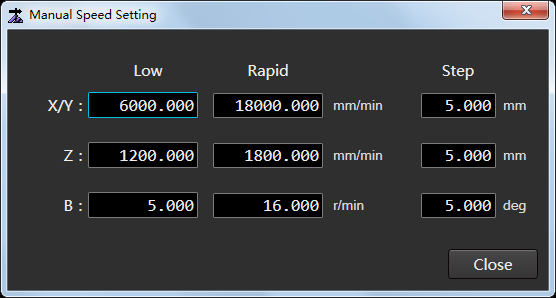

To separately set low speed, rapid speed and step size for X/Y-axis, Z-axis and B-axis, click

:

:

Manual Control Area

It is used to move the machine tool.

It is shown as follows:

Axis direction buttons

Used to move each axis towards positive or negative direction.

Feed mode buttons

To switch to Jog mode, click Jog.

In this mode, click an axis direction button or several axis direction buttons. The clicked axis/axes move(s) at jog speed until you release the button(s).

To switch to Rapid Jog, click Jog → Rapid.

In this mode, click an axis direction button or several axis direction buttons. The clicked axis/axes move(s) at rapid jog speed until you release the button(s).

To switch to Step mode, click Step.

Click an axis direction button. The clicked axis moves the customized step size.

The default customized step size is 5mm. And you can customize the step size in axis coordinate display area.

Note: Please do not click an axis direction button too frequently because the system needs a certain time to execute the command.

Feed override area

Used to adjust the current feed override before machining to during machining, so as to adjust G00 speed or machining speed.

The relation between G00 speed or machining speed and feed override is as follows:

Current rapid traverse speed/machining speed = Current feed override * Set value of G00/machining speedTo adjust feed override, do one of the following:

- Drag the slider.

- Click the target position on the slider.

- Click the slider and press PgUp / PgDn or ↑ / ↓ on the keyboard.

Common Operation Buttons

It is used to execute the following common operations:

: Set origin

: Set originUsed to set the workpiece origin.

: To origin

: To originUsed to move the feeding axis, horizontal moving axis, lifting axis, rotary axis or focus axis to workpiece origin.

: Go home

: Go homeUsed to return all axes to the machine origin.

: Z home

: Z homeUsed to return Z-axis to the machine origin.

: Calibrate

: CalibrateUsed to set a follow-up height.

Machining Control Area

It includes the following:

: Start

: StartUsed to start machining from the beginning.

: Stop

: StopUsed to stop machining.

: Resume

: ResumeUsed to resume machining from the exact interrupted position when the power interruption or e-stop occurs and the workpiece origin is secured.

: Simu

: SimuUsed to execute simulation to check the toolpath in real-time.

: Dry run

: Dry runUsed to run the machine tool without turning on related ports of laser and machining. There is no actual machining.

: Return to center

: Return to centerUsed to move the rotary axis to the workpiece origin or the horizontal moving axis to the center line of the tube.

See Execute Returning to the Center for details.

: Tube centering

: Tube centeringUsed to adjust the tube horizontally and find the center line for a certain face of the tube.

See Level and Center the Tube for details.

: Centering mode

: Centering modeUsed to switch between the following centering modes:

- Standard: levelling + centering

- Simple: centering

: F chuck released

: F chuck releasedUsed to control the unclamping of the front chuck.

After setting the chuck control type in the system parameters, the chuck can be controlled by IO / torque / position.

: F chuck clamped

: F chuck clampedUsed to control the clamping of the front chuck.

After setting the chuck control type in the system parameters, the chuck can be controlled by IO / torque / position.

: B chuck released

: B chuck releasedUsed to control the unclamping of the back chuck.

: B chuck clamped

: B chuck clampedUsed to control the clamping of the back chuck.

: Laser

: LaserUsed to turn on/off the laser valve.

It is automatically turned on when machining starts.

: Shutter

: ShutterUsed to manually turn on laser shutter.

To eject laser light, first, turn on the laser shutter; then, open the laser valve.

: Red light

: Red lightUsed to manually turn on the red light.

It is used as a kind of guide light to point out the laser position on the tube.

: Burst

: BurstUsed to turn on the laser valve for a certain time.

It keeps on for the set burst time until it is turned off automatically.

: Dispose tailing

: Dispose tailingUsed to dispose the tailing.

During disposing the tailing, please ensure the following:

The system is in idle status.

The feeding axis, horizontal moving axis, lifting axis, clamping axis for blanking plate, forward and backward moving axis for blanking plate have been returned to the machine origin.

: Follow-up

: Follow-upUsed to turn on follow-up valve, to keep the distance between the nozzle and the workpiece surface a fixed value.

It is turned on automatically when machining starts.

: Air

: AirWhen machining starts, the button is highlighted. The system automatically turns on the blowing valve and blows air.

: Oxygen

: OxygenWhen machining starts, the button is highlighted. The system automatically turns on the blowing valve and blows oxygen.

: Nitrogen

: NitrogenWhen machining starts, the button is highlighted. The system automatically turns on the blowing valve and blows nitrogen.

: Auto loaded

: Auto loadedUsed to automatically load material after setting parameter Enable Automatic Loading Device to Yes.

: Fan

: FanUsed to turn on the fan.

: Deslag

: DeslagUsed to automatically deslagging after setting parameter Enable Back Blow or Enable Side Blow to Yes.

: Lubricate

: LubricateUsed to turn on lube.

: Edge find

: Edge findWith the button clicked, the cutting head starts to find the tube edge.

: Reserved

: Reserved

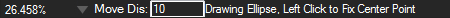

Status Area

It is shown as follows:

You can check the following in the area:

Related information of current drawing objects: drawing steps and meaning, step result, tuning distance, etc.

Tips during machining.

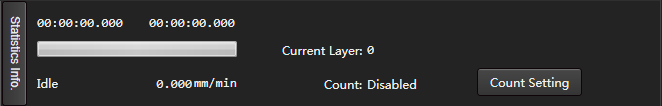

Statistics Area

It is shown as follows:

You can do the following in the area:

To open Statistic Information dialog box, click Statistics Info.

See Check Statistics for details.

To open Count Setting dialog box, click Count Setting.

See Count Machining for details.

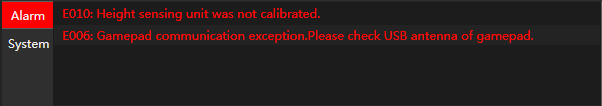

Alarm/System Info Area

It is shown as follows:

You can do the following in the area:

To open Log dialog box, double click Alarm / System.

See Check System Logs for details.

To troubleshoot the alarm or check the log details, double click the related alarm items or system information items.

Drawing Tool bar

It is used to do the following:

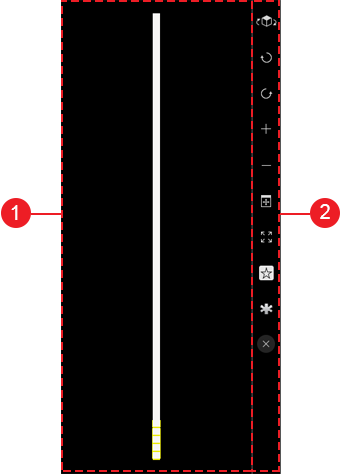

3D View Area

It is shown as follows:

View Area

It is used to check the tube from different perspectives and preview cutting effect.

In this area, you can do the following:

Press the left button:

- To rotate the tube, drag the mouse left and right.

- To move the tube, drag the mouse up and down.

To zoom in/out the tube, scroll the mouse wheel.

View Tool Bar

It includes the following:

: Switch view

: Switch viewUsed to observe a tube from different perspectives.

: Rotate CW

: Rotate CWUsed to rotate the view in a clockwise direction.

: Rotate CCW

: Rotate CCWUsed to rotate the tube view in a counterclockwise direction.

: Zoom in

: Zoom inUsed to make the view appear larger.

: Zoom out

: Zoom outUsed to make the view appear smaller.

: Best view

: Best viewUsed to adjust 3D view area to the best size, so as to check the toolpath effect.

: Maximize

: MaximizeUsed to maximize 3D view area and hide drawing window.

: Hollow out

: Hollow outUsed to show hollow-out-effect of objects, so as to check the cutting effect.

: Solid

: SolidOpposite to

instruction.

instruction. : Instant Hollowing

: Instant HollowingUsed to show hollow-out-effect of objects which have been executed machining or dry run, while executing

instruction for other objects.

instruction for other objects. : Tube cutting setting

: Tube cutting settingUsed to open Tube Cutting Setting dialog box. See Set the Tube Type and Size for details.

: Close

: CloseUsed to close 3D view area.