Special Pull Material Function Use Instruction

This chapter is only used for debugging personnel to use and configure the special pulling function. According to different models, cooperate with the process edit function to achieve reasonable and correct use of the special pulling function.

Model Classification

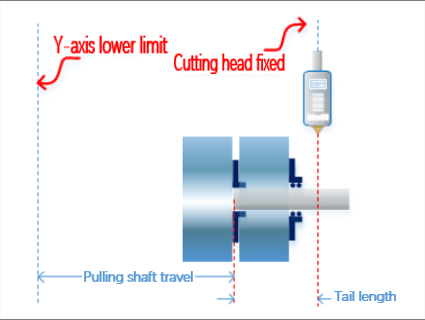

Single Y Pushing Modle

The travel of the Y-axis is short, and the cutting head is fixed

Back chuck can be connected

The Y-axis moving direction is negative to the left and positive to the right

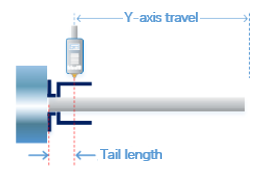

Single Y Pulling Modle

Moving the cutting head to the left is positive, to the right is negative

Pulling device pull material cutting

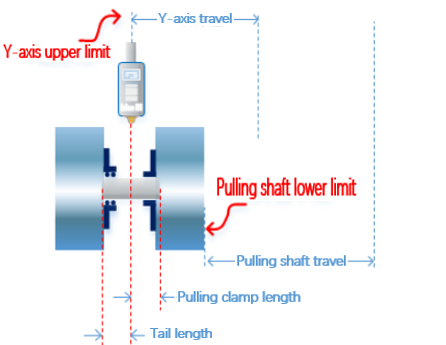

Double Y Pulling Modle

Can realize zero tail cutting function

A pulling shaft is used for pull material, for heavy tubes, and a Y-axis is used for cutting.

The moving direction of the pulling shaft is negative direction to the left, and positive direction to the right

Moving the cutting head to the left is positive, to the right is negative

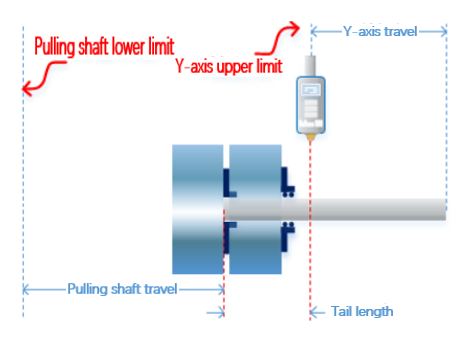

Double Y Pushing Modle

A pulling shaft is used for pushing material, for heavy tubes, and a Y-axis is used for cutting.

The moving direction of the pulling shaft is negative direction to the left, and positive direction to the right

The Y-axis of the cutting head moves to the left is positive, and to the right is negative

Function Application Background

The tube is generally very long. At present, there are many rear chucks on the market that move the tube from the direction of the feed axis, which requires a long Y-axis travel. Some customers have designed the machine tool with cutting head that can segment the tube. The tube can be cut in sections to reduce the size of the machine tool to achieve the purpose of cutting long tubes. That is to say, it is possible to cut long tubes with a small machine tool. Based on this background, the special pulling function has been developed.

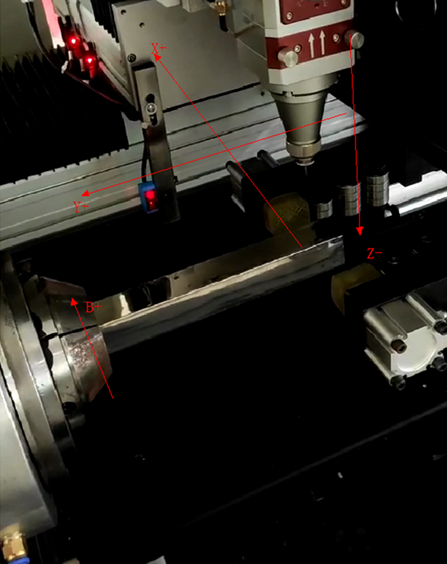

Determination of Machine Coordinate System and Direction

No matter what kind of machine tool, the machine coordinate system and direction are clear and fixed. The following picture is for reference:

Software Version

Single Y pushing modle: TU1000,TU2000,TU3000

Single Y pulling modle: TU1000,TU2000,TU3000

Double Y pushing modle: TU3200,TU6000

Double Y pulling modle: TU3200,TU6000

Detailed Explanation of Special Pulling Function

Machining Process

Parameter Configuration

According to different model configuration parameters and edit process actions.

Operation Steps:

Enter the configuration console and configuration entry: C:\Program Files\Weihong\NcStudio\Bin. Find NcConfig.

According to different models and device types, configure parameters and configure related actions in flow edit:

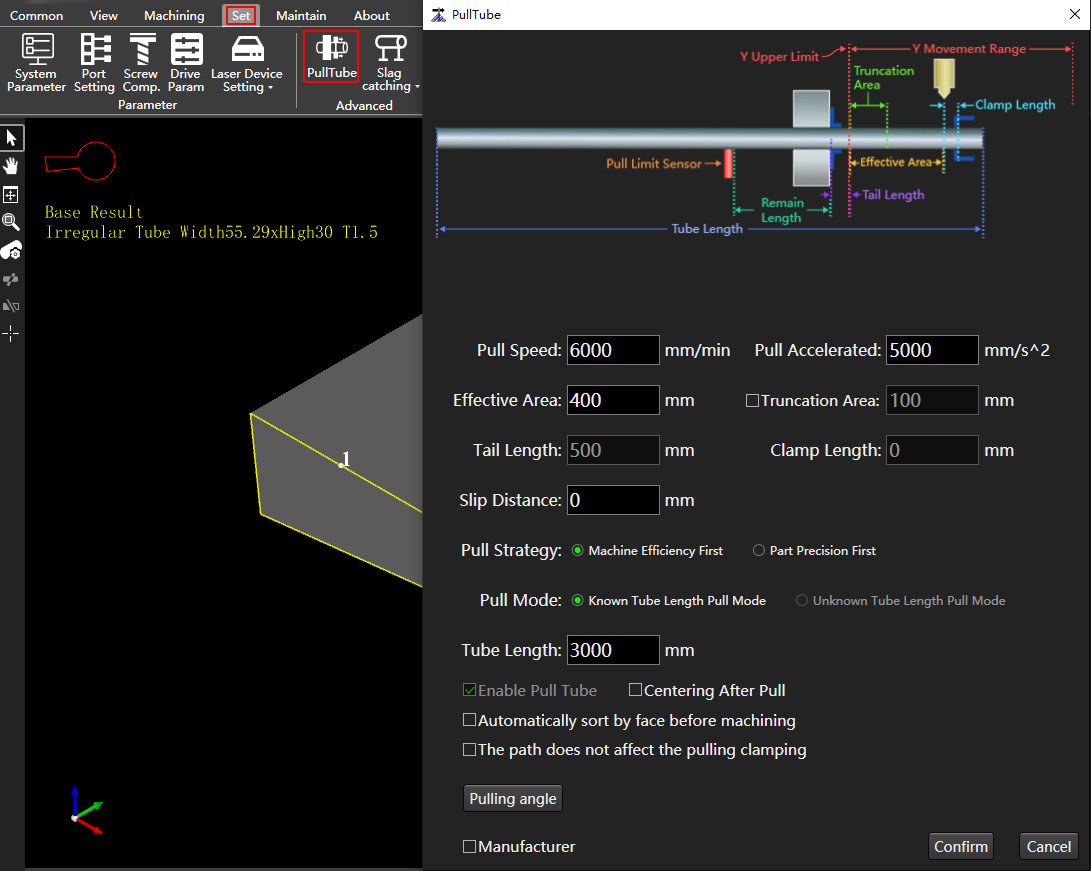

In the software, configure the function parameters

Parameter interpretation:

Pull shaft: The single Y pulling model defaults to Y, no need to change.

Pull speed: The speed of the Y-axis when pull material is different from the speed of the Y-axis.

Pull accelerated: The acceleration of the Y-axis when pull material is different from the G00 acceleration of the Y-axis.

Effective area: The maximum range for machining a single primitive. For example, the effective machining area is 100, and if the length of a certain contour is greater than 100, it will not be machined.

Truncation area: The maximum range from the cutoff line to the upper limit of the Y-axis. When this function is turned on, the cutoff line can be cut off close to the chuck, which is more stable.

Tail length: The distance from the clamped tube to the cutting head when the rear chuck travels to the maximum Y travel.

Clamp length: This parameter is meaningless for single Y pushing model. Is 0.

Slip distance: After each pulling, the tube fittings will have a certain length error due to external factors. This parameter can be used to improve the length error and be set according to the actual situation.

Machine efficiency first: The material pulling time is less, and the machining efficiency is relatively high, but because the pulling is triggered during cutting, the relative accuracy is reduced.

Part precision first: There are many times of pulling, and the machining efficiency is low, but it can ensure that materials will not be pulled during cutting.

Know tube length pull mode: The tube length is fixed, use the tube length parameters and drawings to determine whether to start machining.

Tube length: Cut the length of the tube, this option does not take effect when the indeterminate length tube mode is selected.

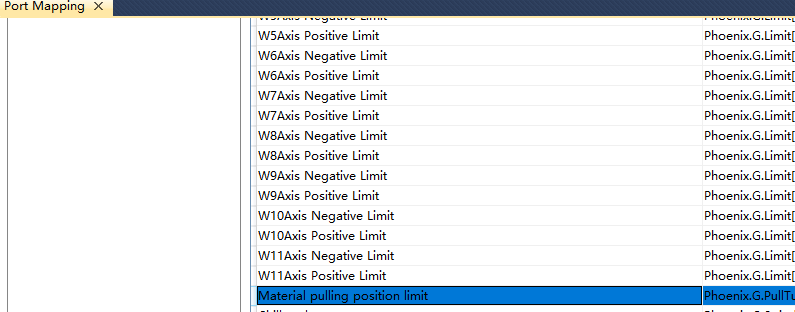

Unknow tube length pull mode: It is used when the length of the tube is not fixed, and it is judged whether the machining can be continued according to the limit port of the pull material. This function can only be selected after the pull limit is configured. The port configuration entry is as follows:

Check enable pull tube, and the pull tube function will take effect.

Centering after pull: After checking this option, the centering will be performed automatically after each pull.

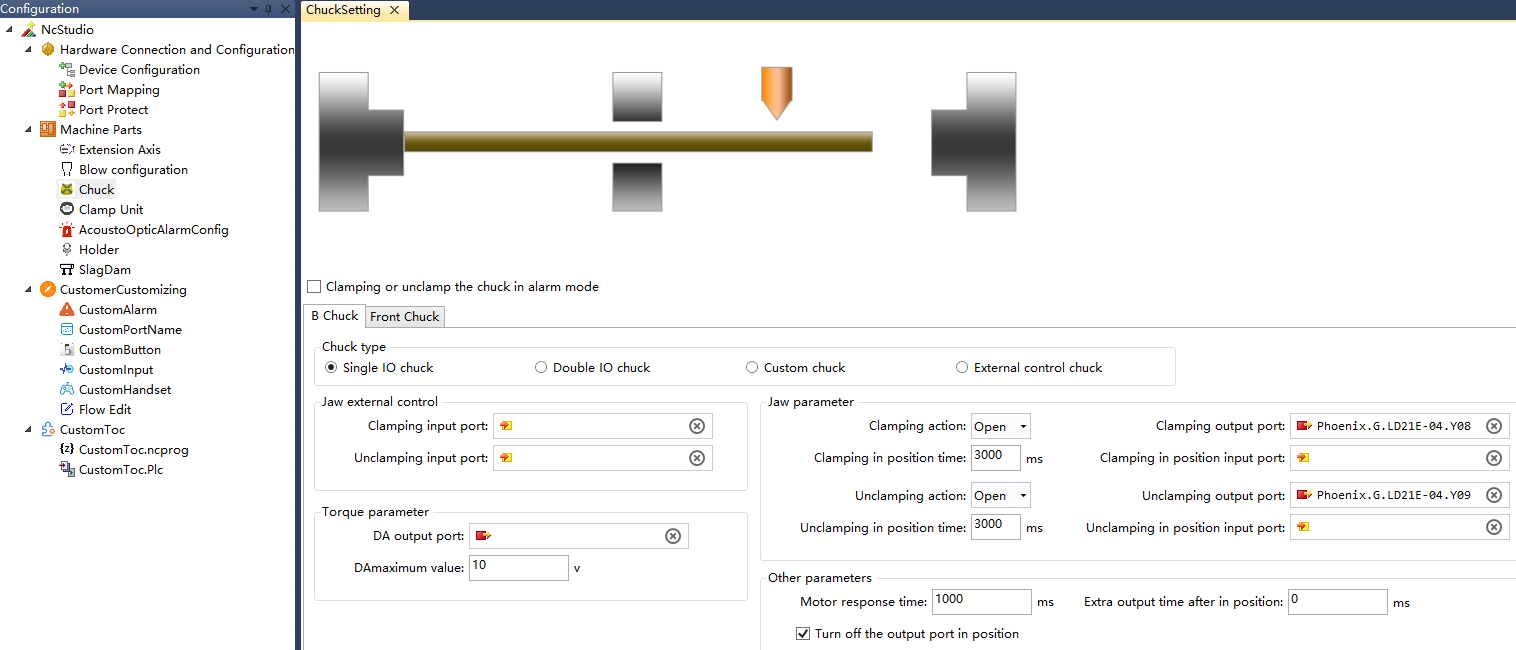

Single Y Pushing (Chuck Type)

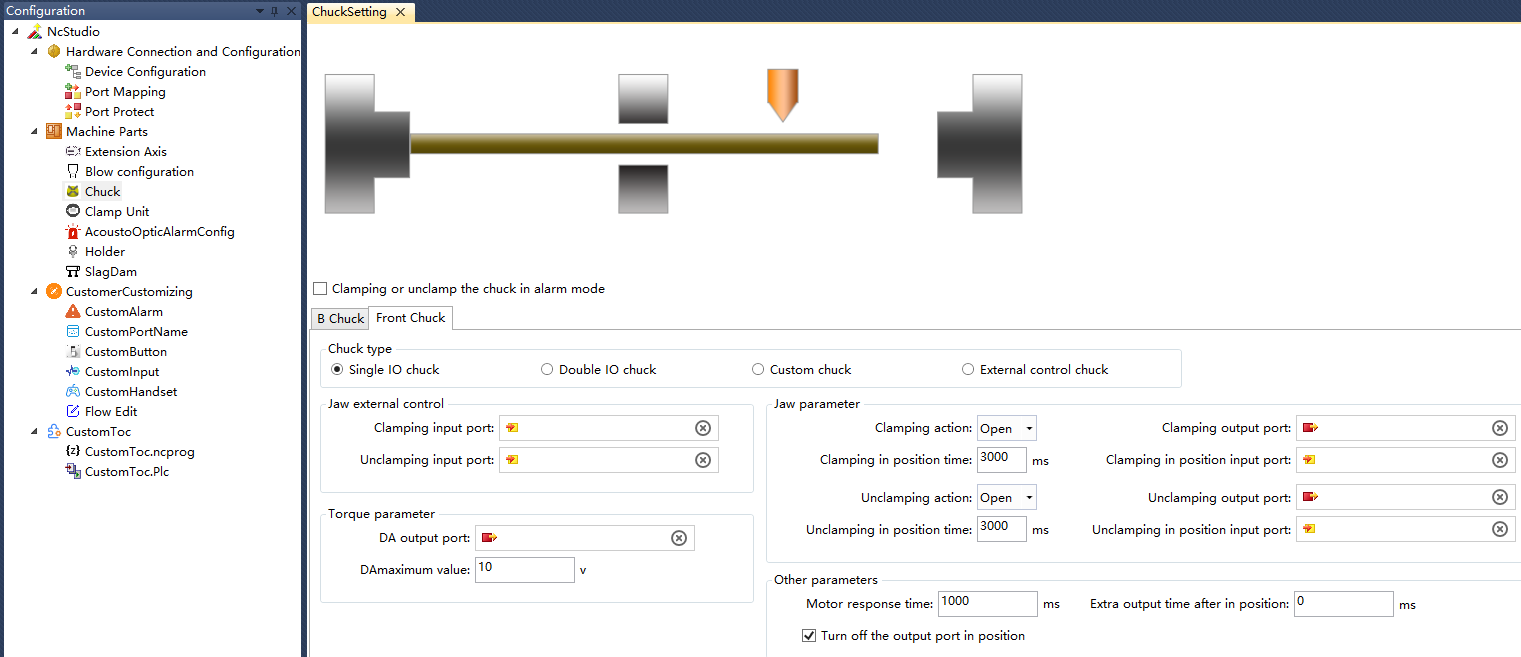

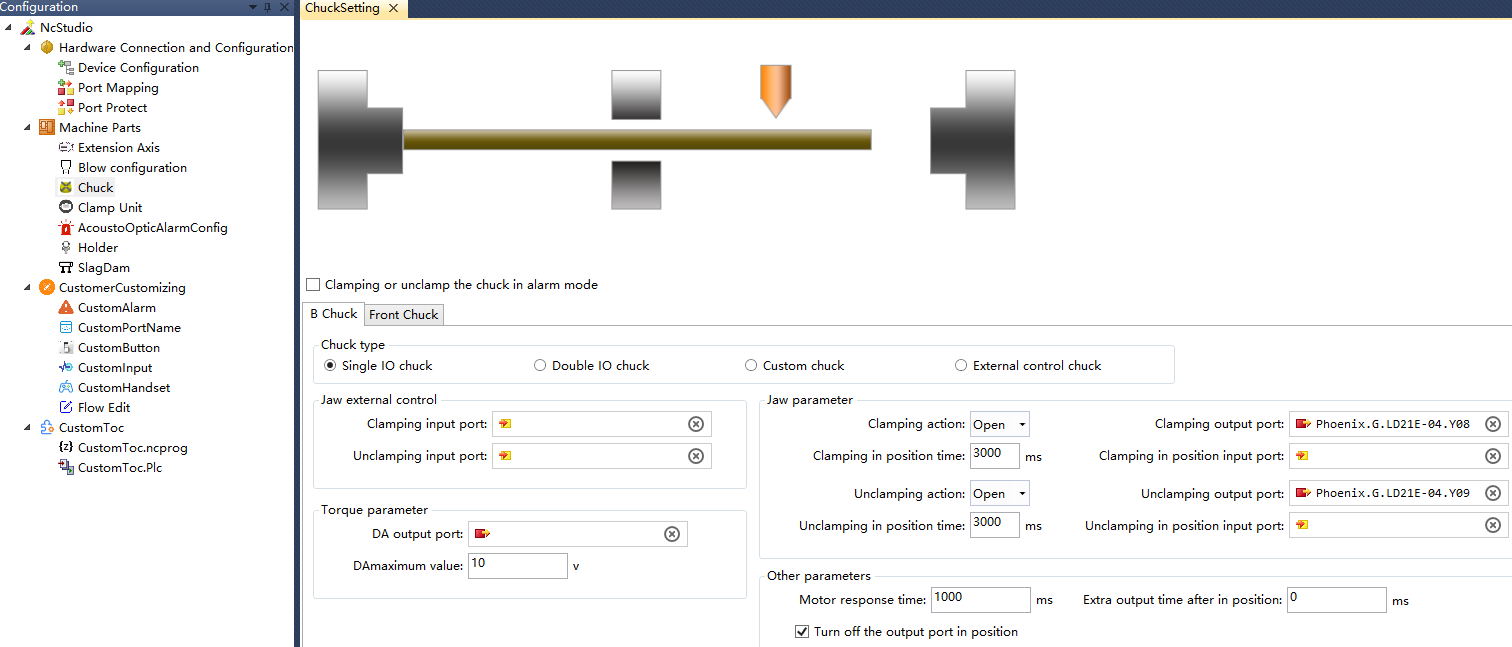

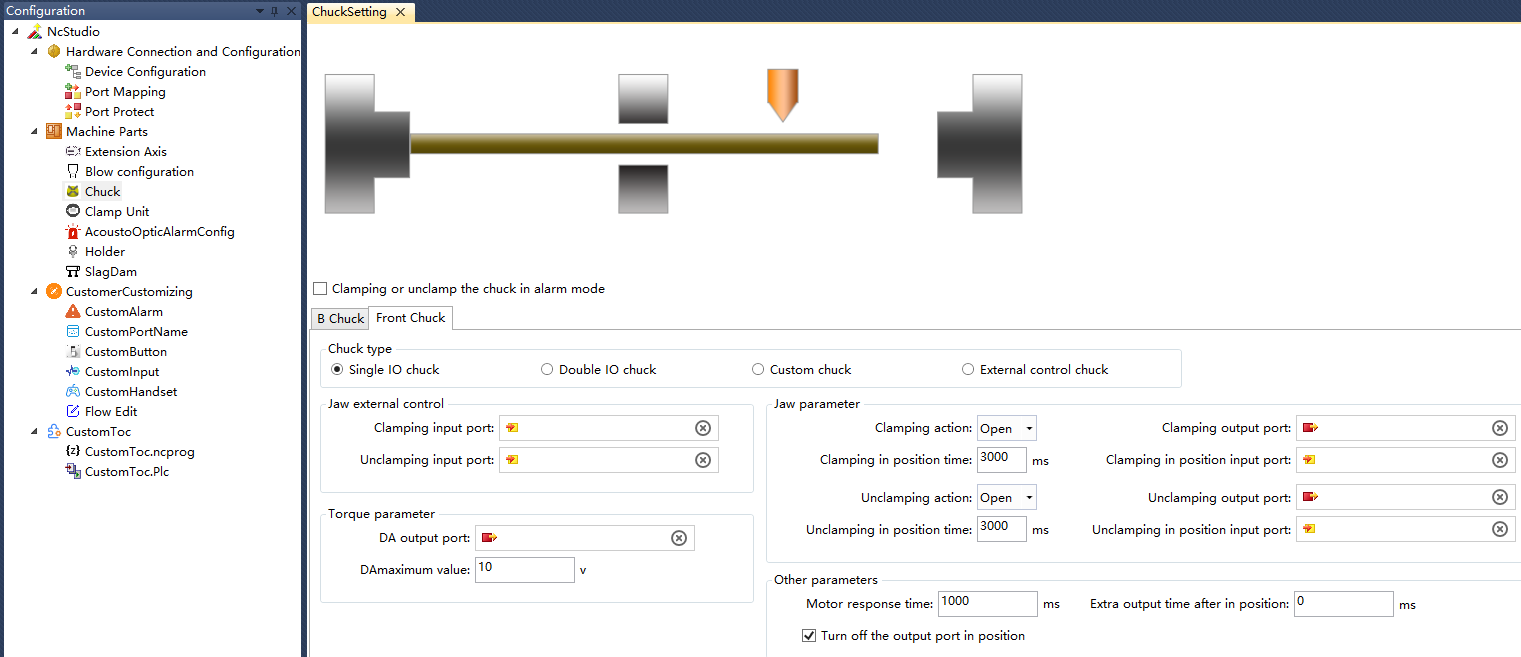

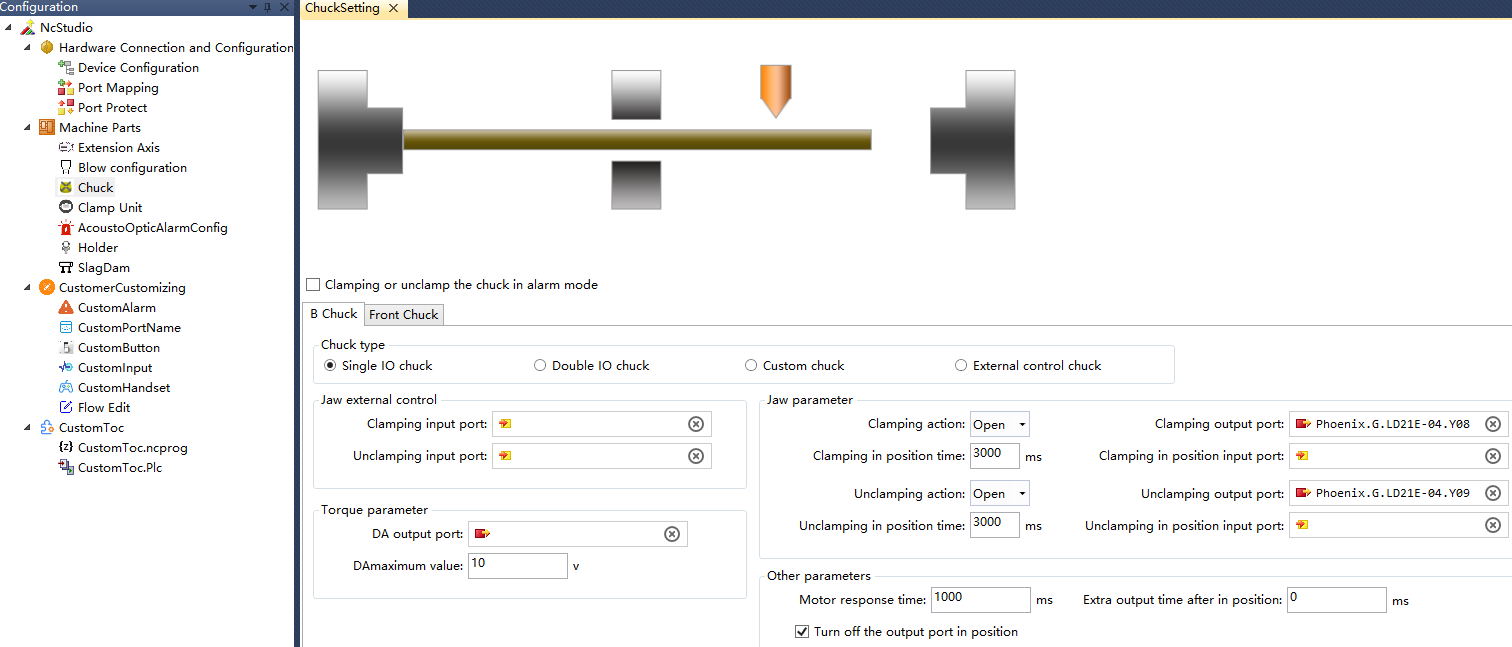

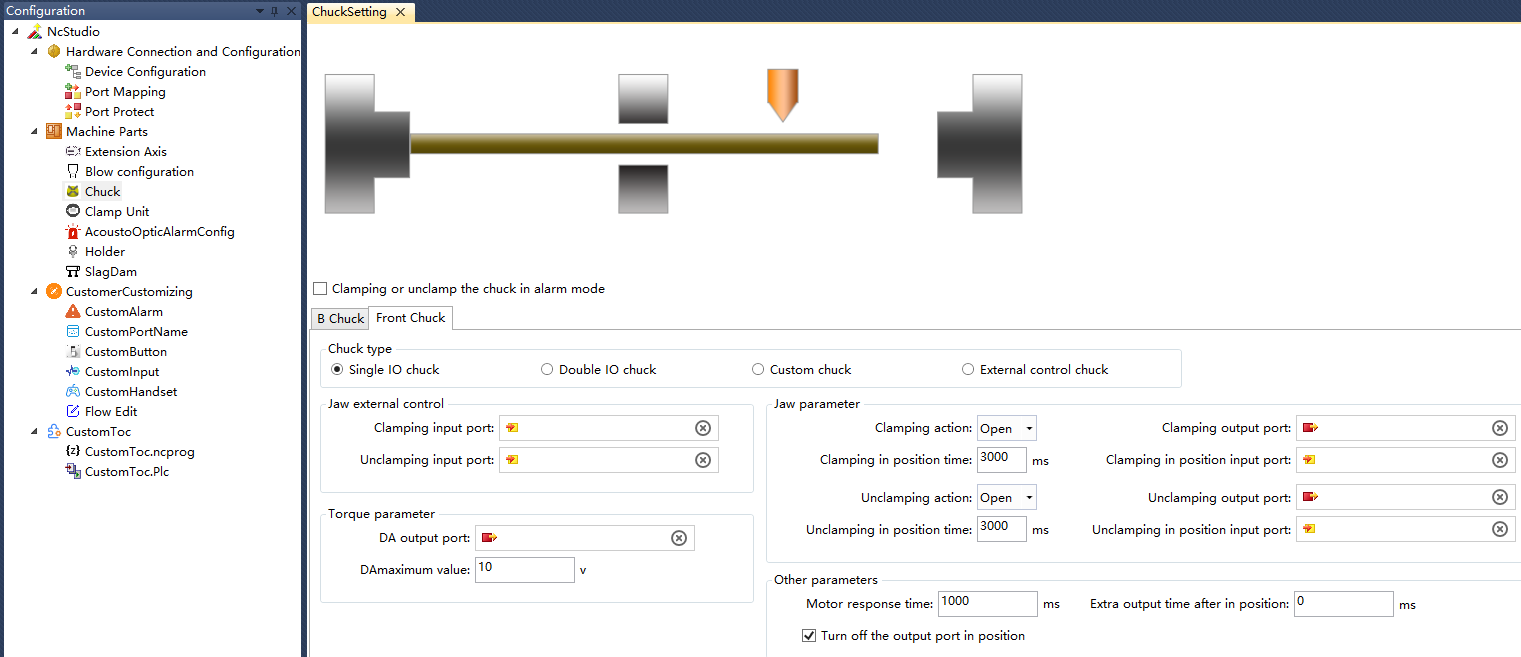

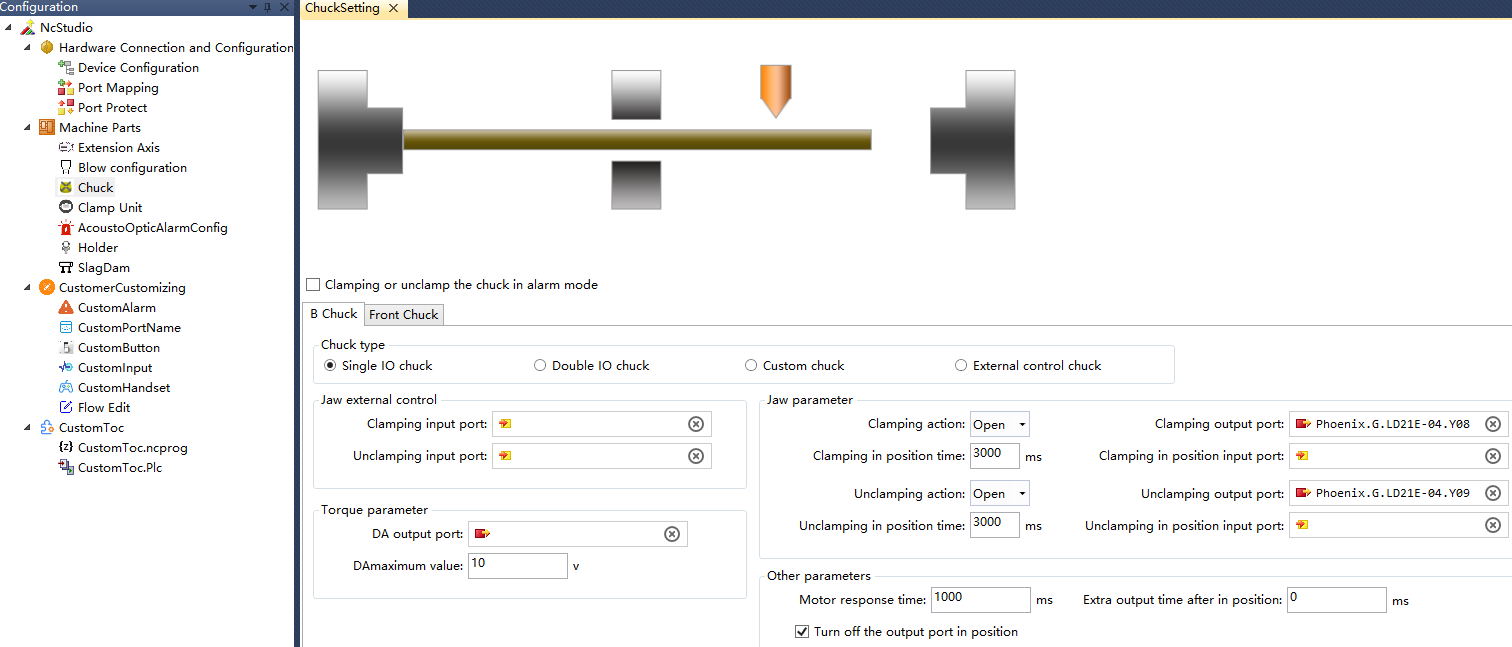

Find the chuck parameters and configure the chuck jaw parameters:

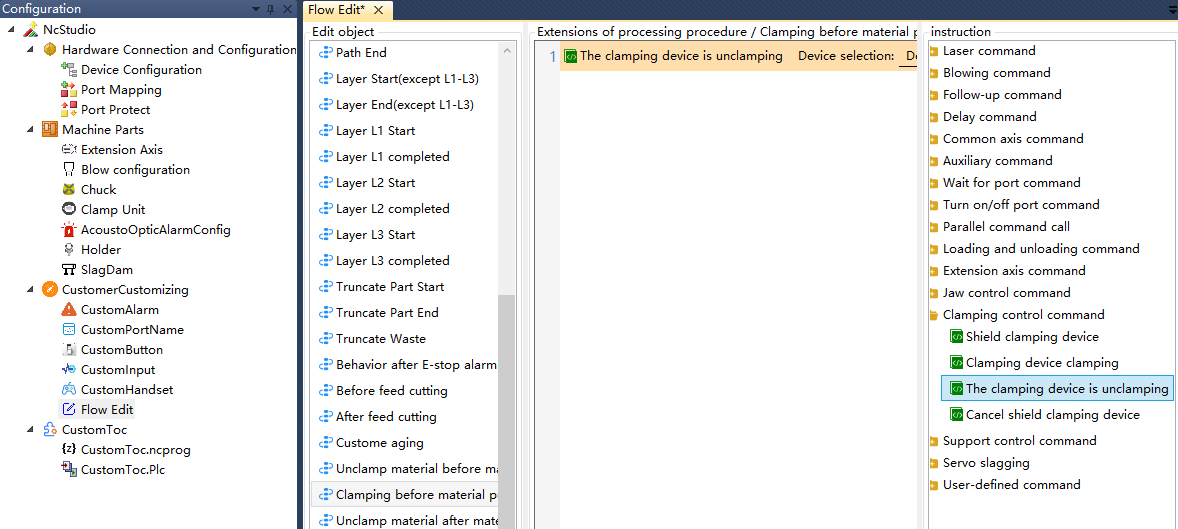

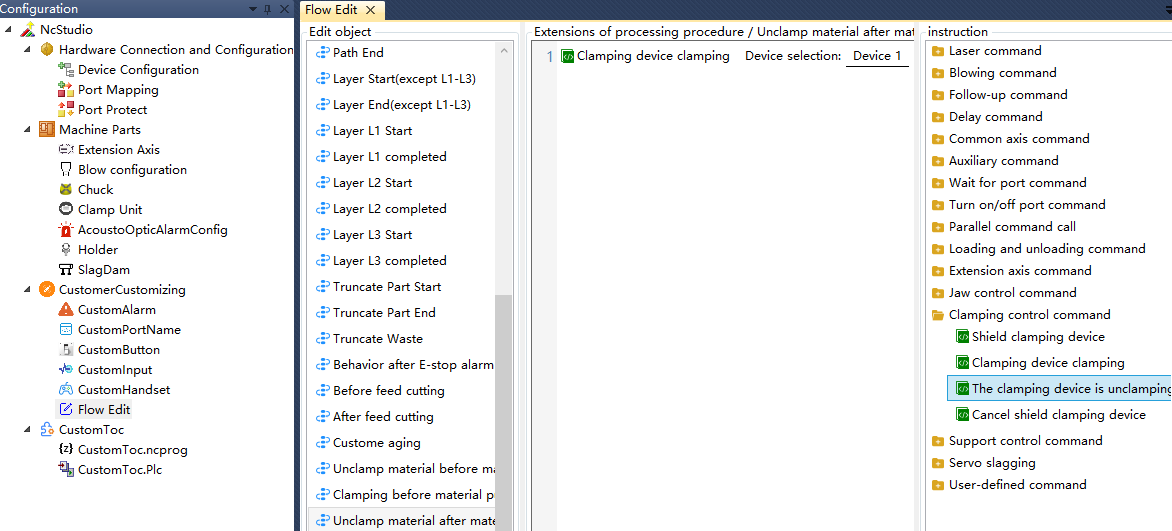

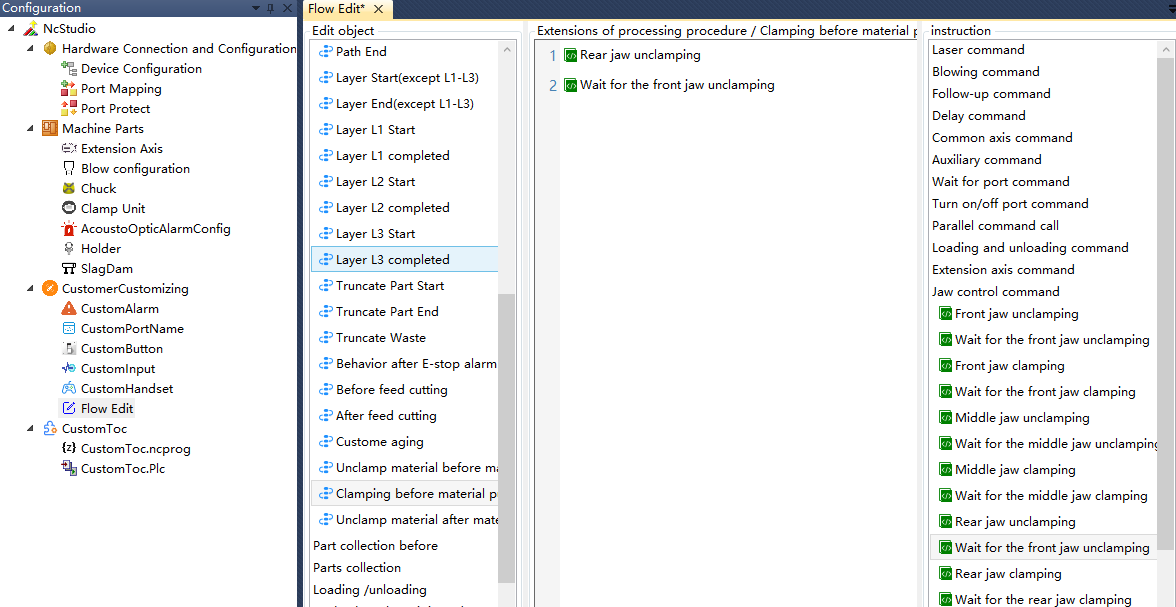

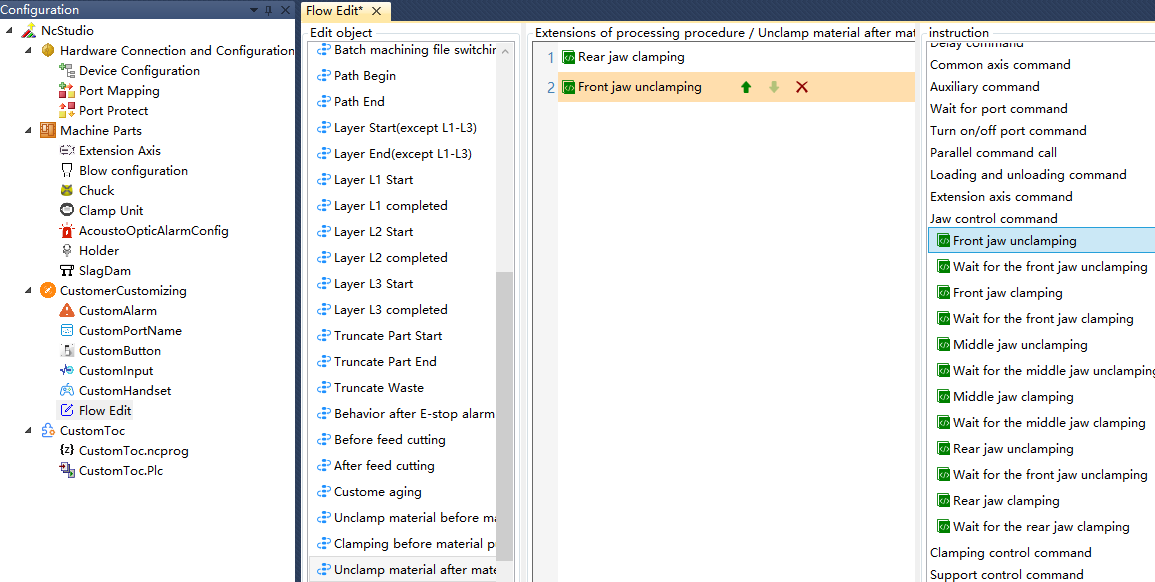

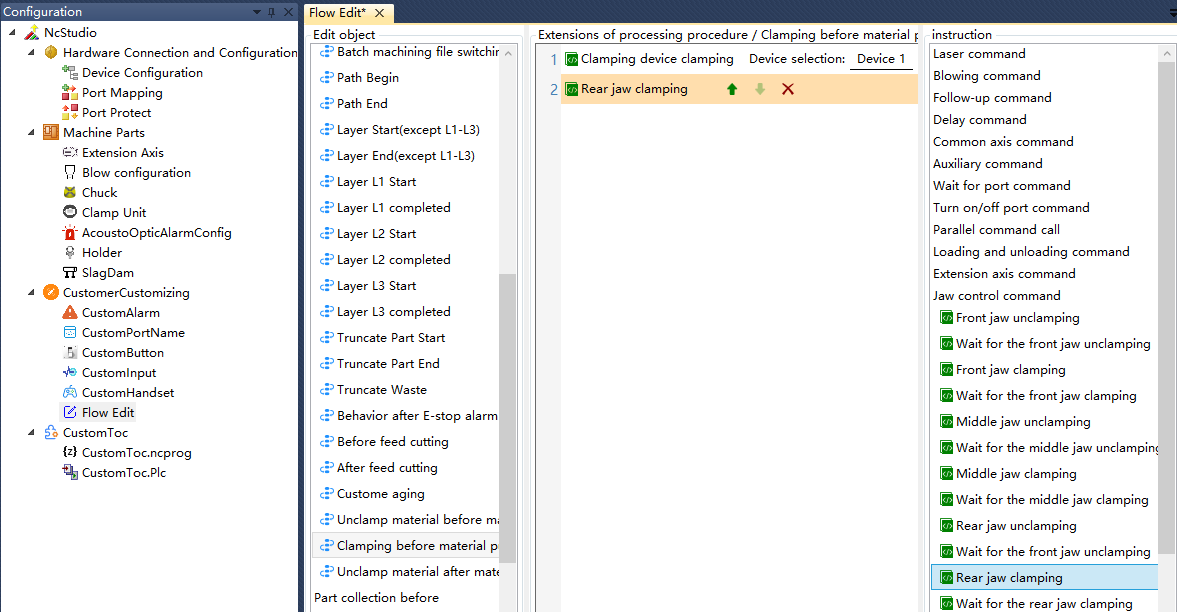

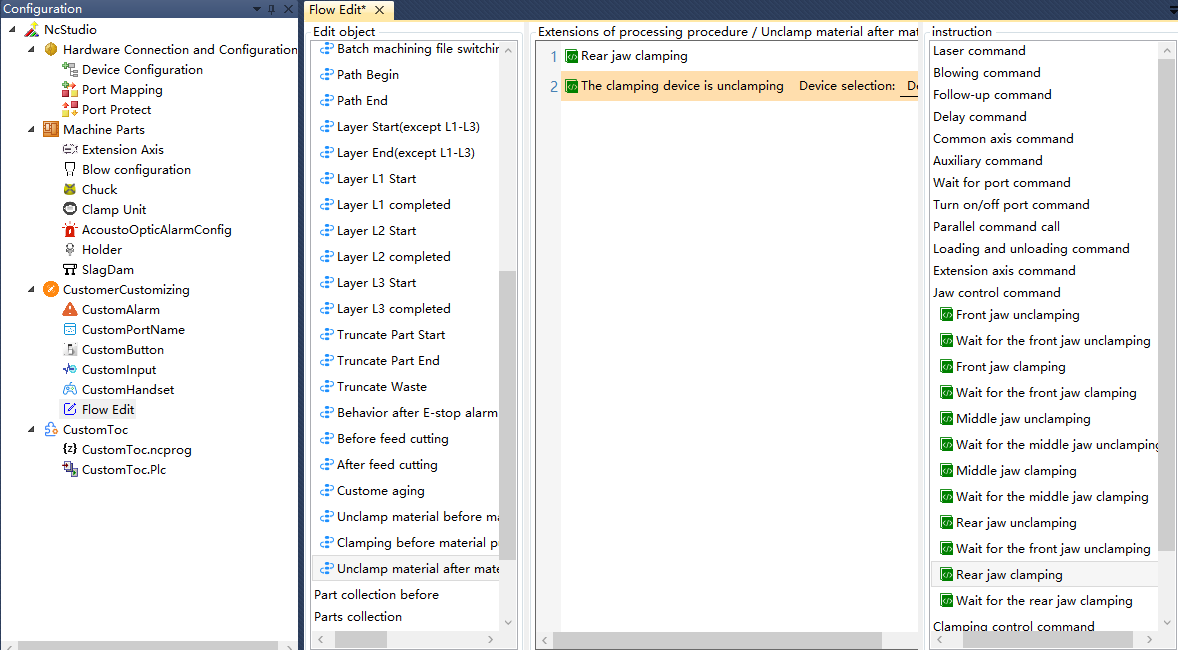

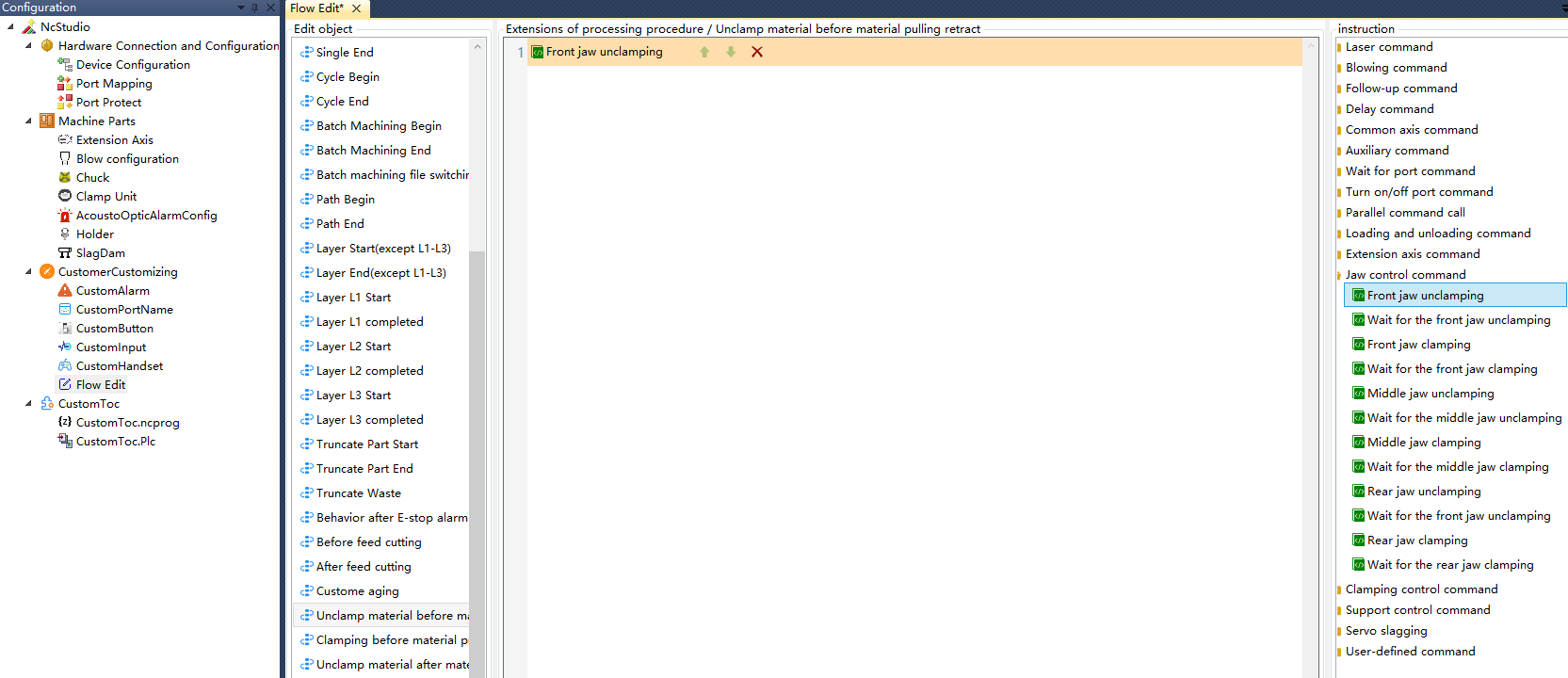

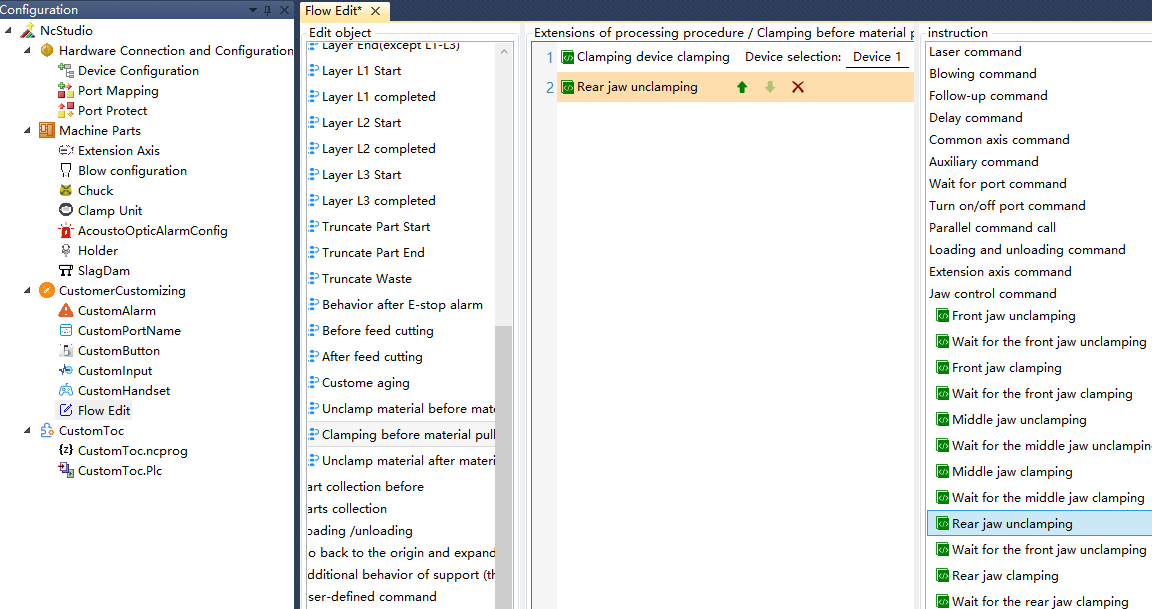

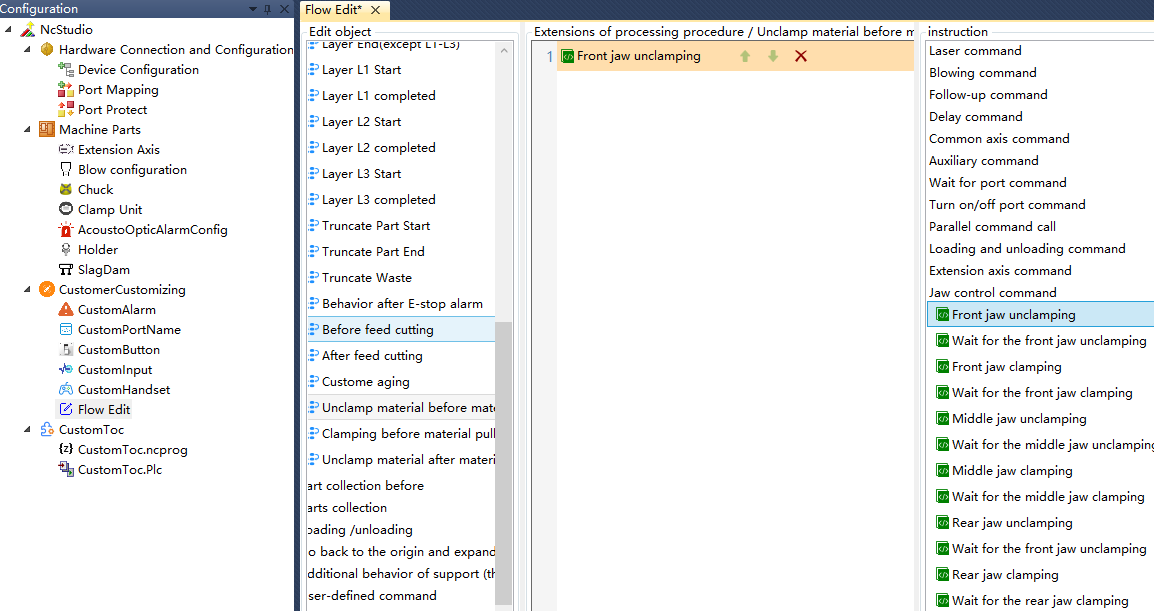

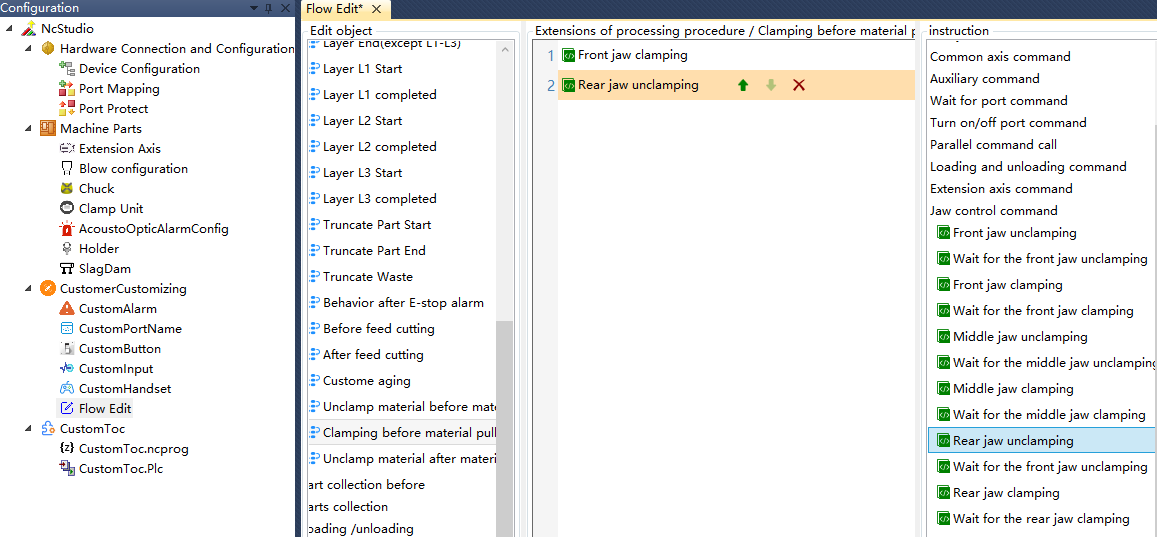

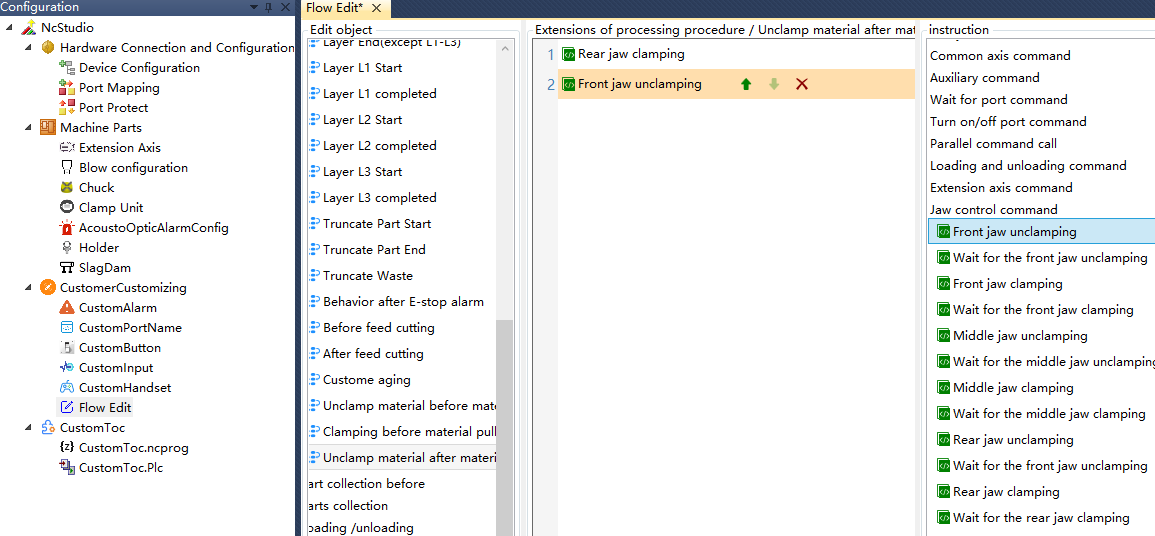

Configure related actions in flow edit:

The following is only the basic configuration. If there are other actions that need to be configured, they can be freely configured in the flow edit.

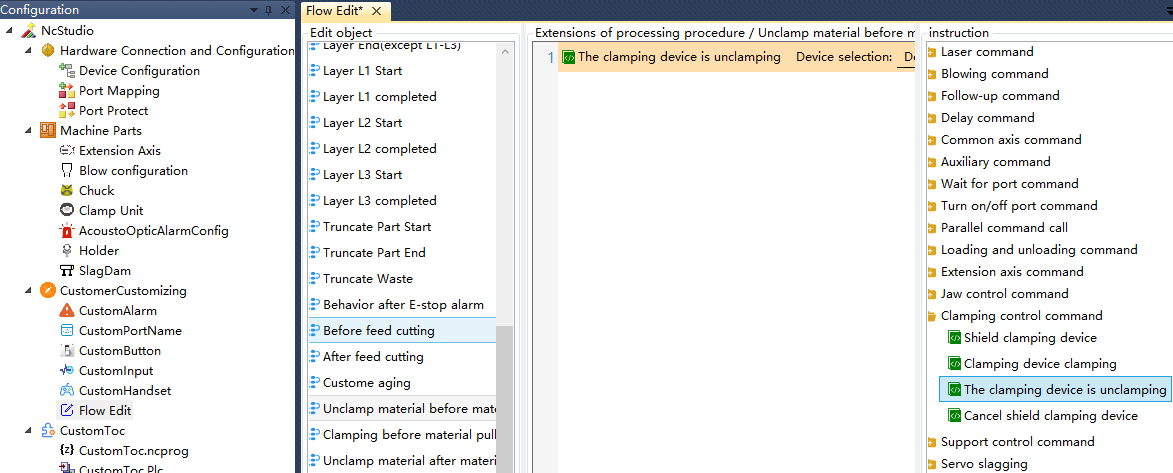

Single Y Pushing (Chuck Device Type)

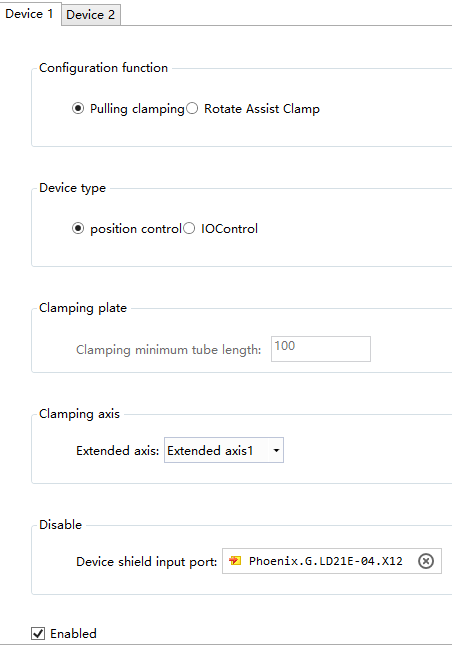

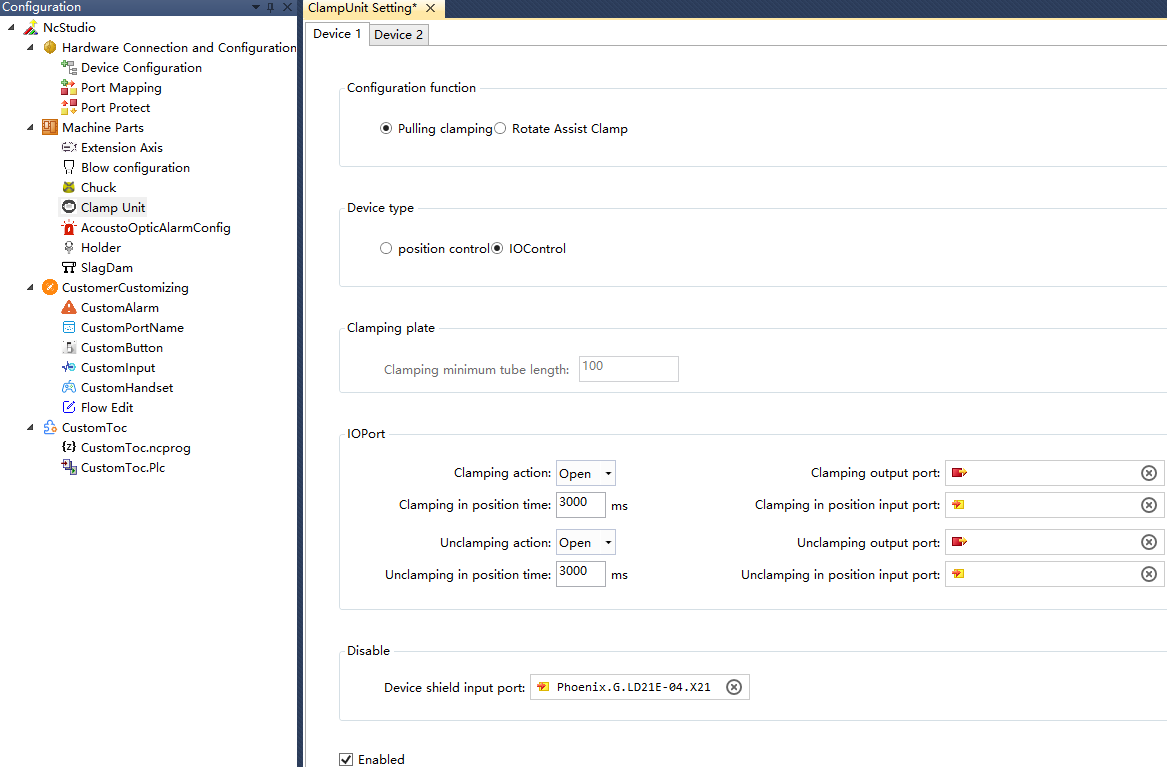

Find the clamp unit setting and configure related parameters:

Position Controlled Device:

Clamping minimum tube length: After the pulling function is stopped, the maximum distance that the clamping plate can be opened to avoid interference between the tube and the clamping device.

Extended axis: Select the servo controlled axis for pulling.

Device shield input port, servo pulling can not be configured.

IO Control Device:

Device shield input port: When there is a signal at this port, the clamping plate is always in the open position and cannot be clamped.

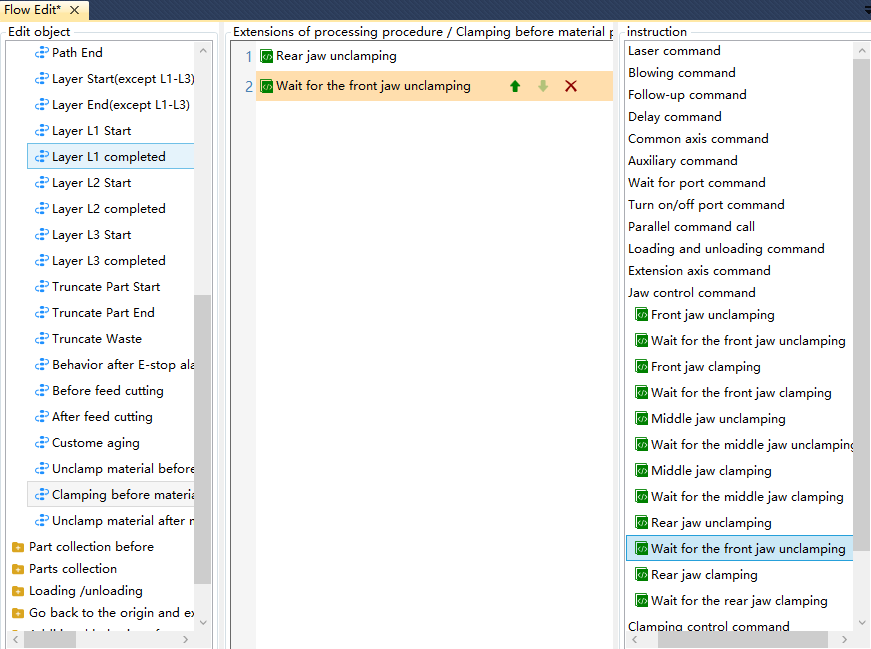

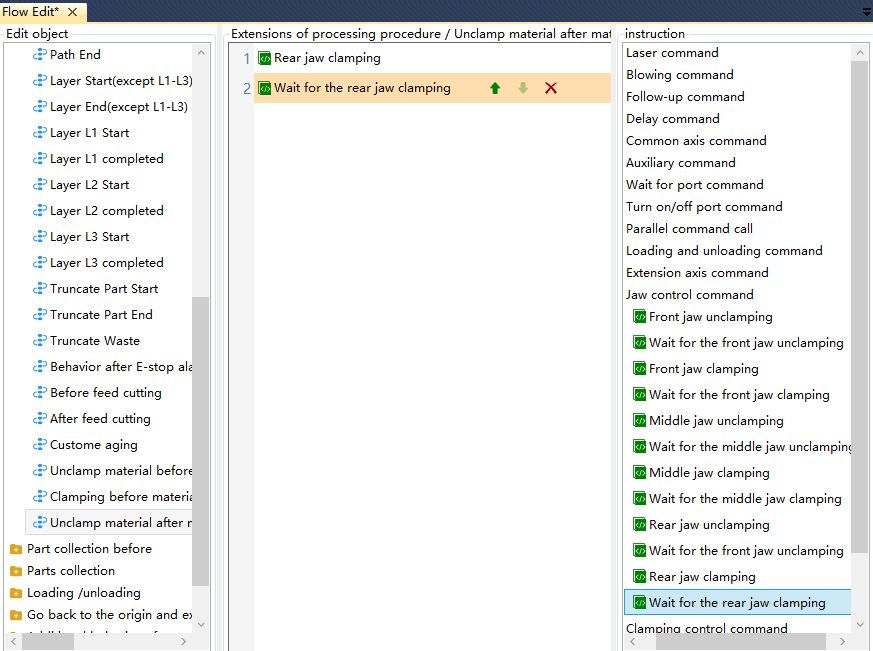

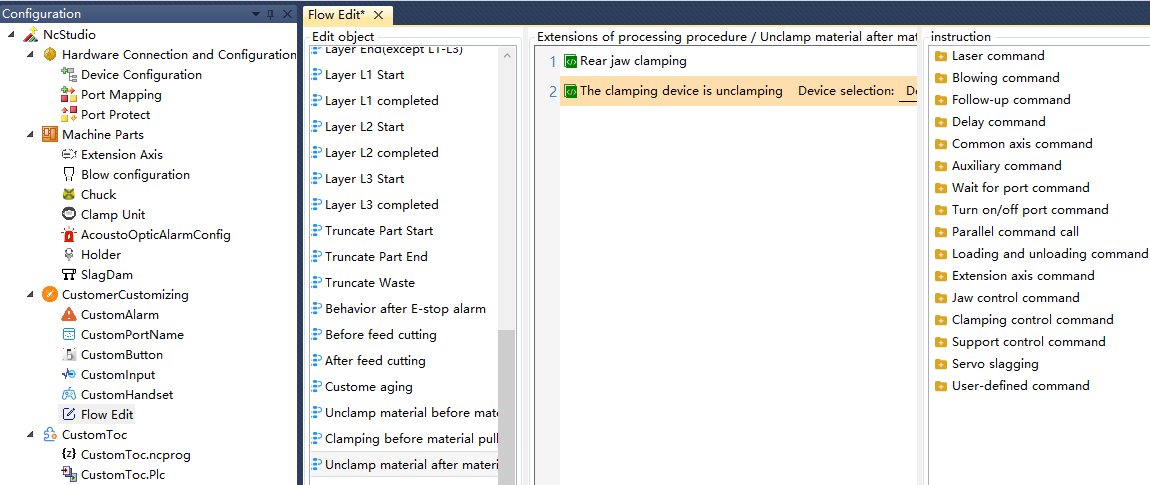

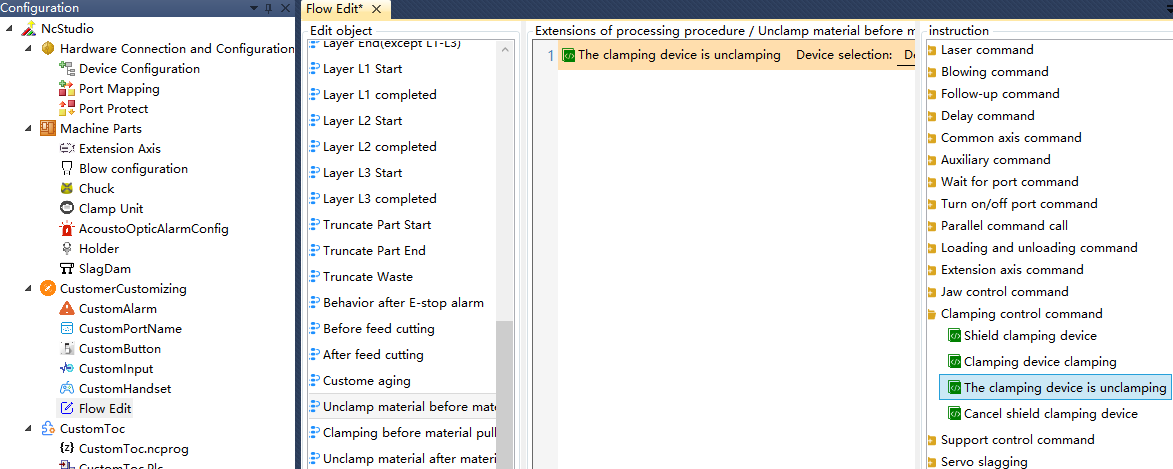

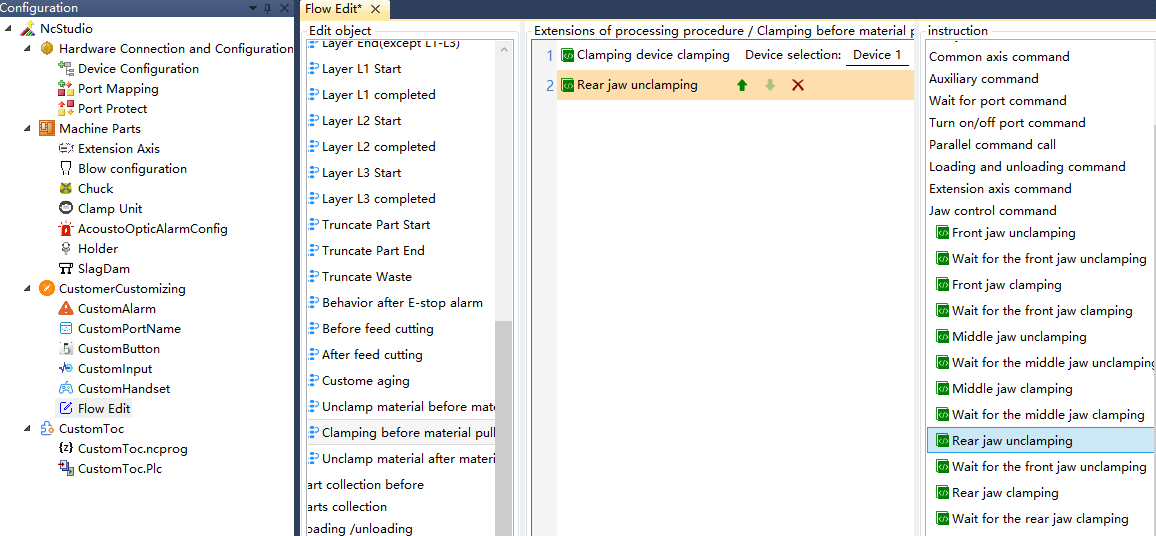

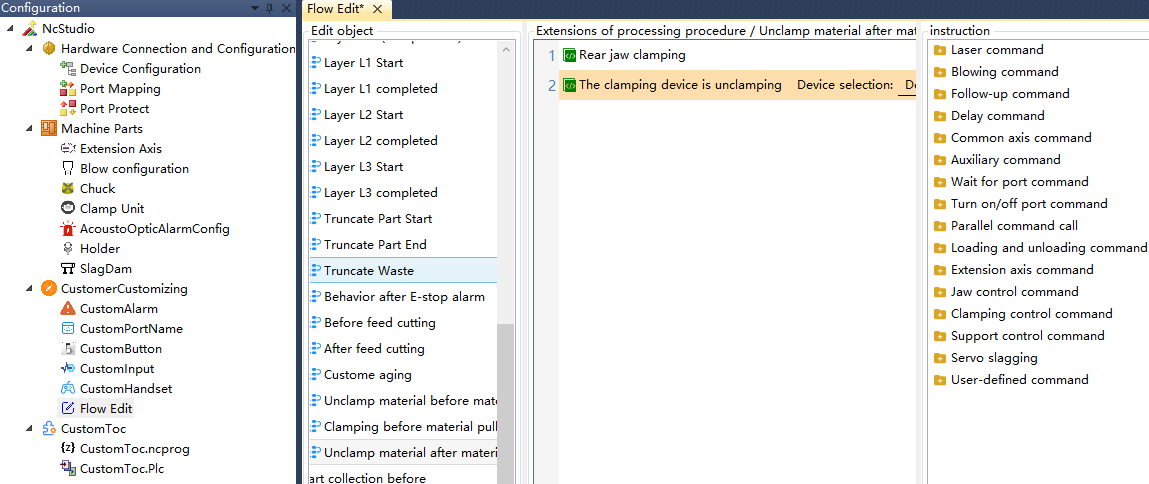

Configure related actions in flow edit:

The following is only the basic configuration. If there are other actions that need to be configured, they can be freely configured in the flow edit.

Single Y Pulling (Chuck Type)

Find the chuck parameters and configure the front and rear jaw parameters:

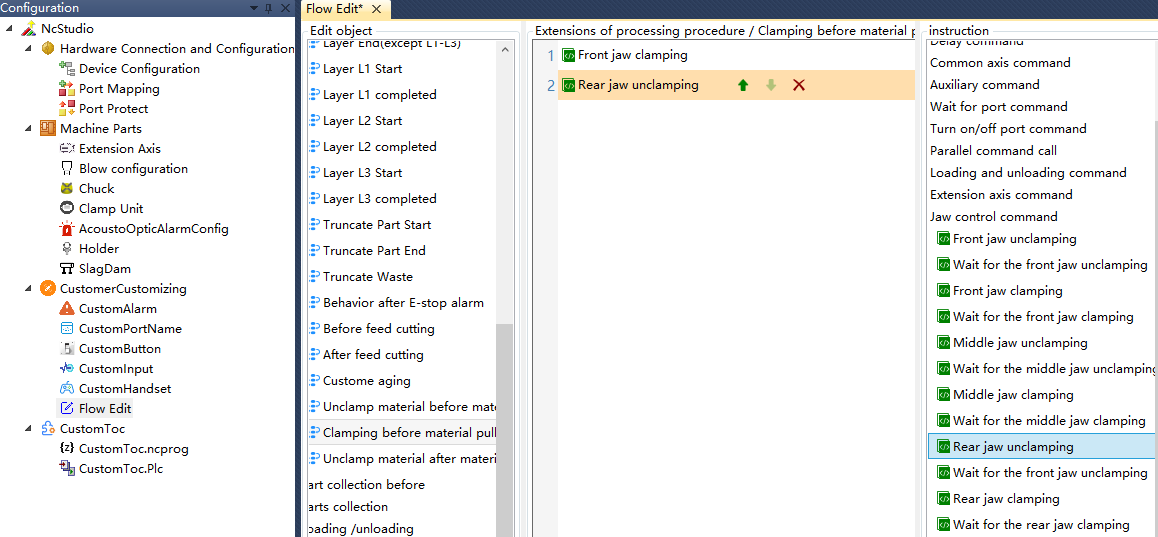

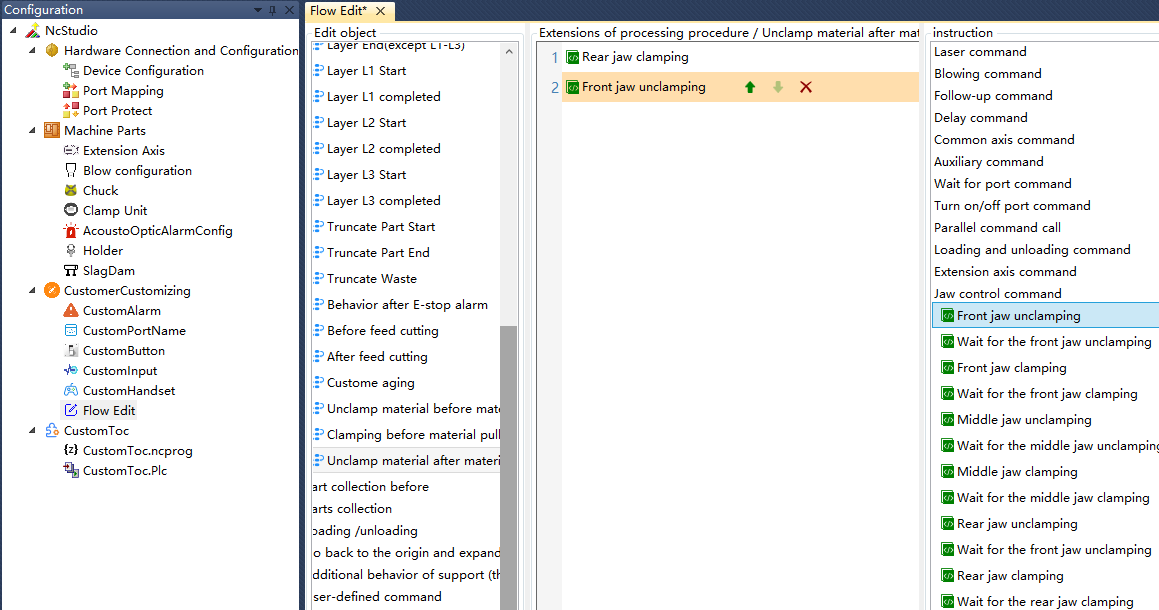

Configure related actions in flow edit:

The following is only the basic configuration. If there are other actions that need to be configured, they can be freely configured in the flow edit.

Single Y Pulling (Chuck Device Type)

Find the parameters of the clamping device and configure the relevant parameters. For details, please see Single Y Pushing (Chuck Device Type).

Configure related actions in flow edit:

The following is only the basic configuration. If there are other actions that need to be configured, they can be freely configured in the flow edit.

Double Y Pulling (Chuck Type)

Find the chuck parameters and configure the front and rear jaw parameters:

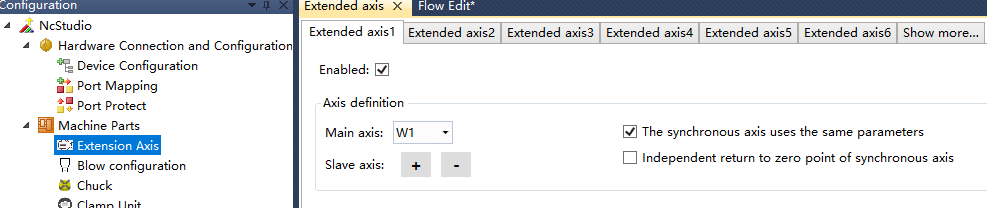

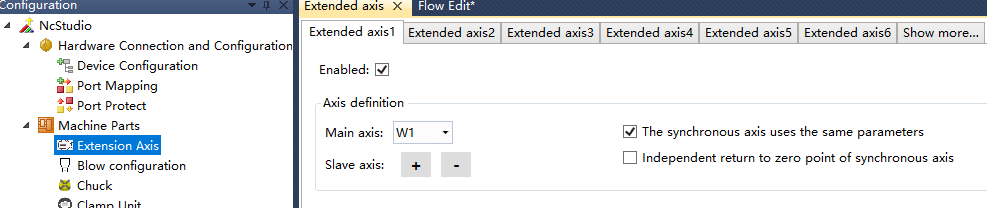

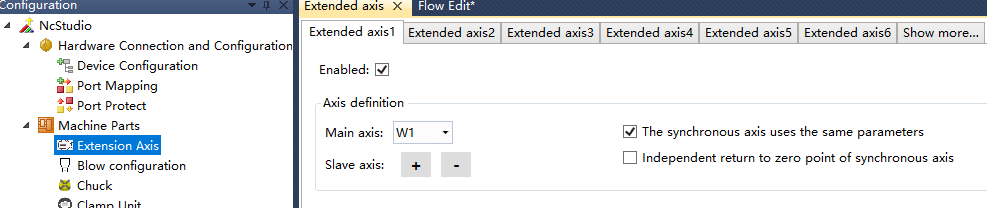

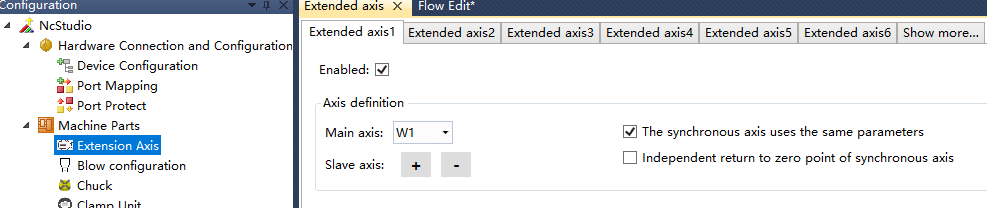

Configure extended axis: Check enable extended axis and select the main axis. If there are synchronous axes, continue to add extended axes among the slave axes.

Configure related actions in flow edit:

The following is only the basic configuration. If there are other actions that need to be configured, they can be freely configured in the flow edit.

1: For the double Y pulling modle, the front chuck must be opened before pulling back. Write in the edit object cutting head avoid before pulling. 2: If there are already cutting parts falling down or in the front chuck at this time, the parts need to be removed manually to prevent interference before continuing to pulling.

Double Y Pulling (Chuck Device Type)

Configure extended axis: Check enable extended axis and select the main axis. If there are synchronous axes, continue to add extended axes among the slave axes.

Find the parameters of the clamping device and configure the relevant parameters. For details, please see Double Y Pulling (Chuck Device Type).

Configure related actions in flow edit:

The following is only the basic configuration. If there are other actions that need to be configured, they can be freely configured in the flow edit.

1: For the double Y pulling modle, the front chuck must be opened before pulling back. Write in the edit object cutting head avoid before pulling. 2: If there are already cutting parts falling down or in the front chuck at this time, the parts need to be removed manually to prevent interference before continuing to pulling.

Double Y Pushing (Chuck Type)

Find the chuck parameters and configure the front and rear jaw parameters:

Configure extended axis: Check enable extended axis and select the main axis. If there are synchronous axes, continue to add extended axes among the slave axes.

Configure related actions in flow edit:

The following is only the basic configuration. If there are other actions that need to be configured, they can be freely configured in the flow edit.

1: For the double Y pushing modle, the front chuck must be opened before pulling back. Write in the edit object cutting head avoid before pulling. 2: If there are already cutting parts falling down or in the front chuck at this time, the parts need to be removed manually to prevent interference before continuing to pushing.

Double Y Pushing (Chuck Device Type)

Configure extended axis: Check enable extended axis and select the main axis. If there are synchronous axes, continue to add extended axes among the slave axes.

Find the parameters of the clamping device and configure the relevant parameters. For details, please see Double Y Pushing (Chuck Device Type).

Configure related actions in flow edit:

The following is only the basic configuration. If there are other actions that need to be configured, they can be freely configured in the flow edit.

1: For the double Y pushing modle, the front chuck must be opened before pulling back. Write in the edit object cutting head avoid before pulling. 2: If there are already cutting parts falling down or in the front chuck at this time, the parts need to be removed manually to prevent interference before continuing to pushing.

Precautions for Using the Special Pull Material Function

The machining length of a single primitive cannot exceed the effective machining area.

Forward and backward across primitives are not supported.

The pull material shaft of the double Y pulling and pushing models is the extension axis, not the Y-axis.

For rear chuck pushing models, the parameter of pulling clamping length is meaningless and can be directly set to 0.