Layer Function

As a core function, layer function is used to set general parameters and technics for a layer. Characteristics of layer function are as follows:

- Combine layer technics and general parameters, making it easy to use.

- With layer technic setting, better cutting effect and higher efficiency can be achieved by setting common parameters, such as laser power, machining speed and so on.

This section introduces the following information about layers:

- Interface overview

- Layer operations

- Layer operation instruction

To specify and set a layer, do the following:

Select the target objects.

Click the target layer in drawing tool bar:

The selected objects turn into the color of the layer.

Each layer has 8 colors and can own different layer technics. Objects with the same color share the same technics.

To open Layer Setting dialog box, do one of the following:

- In layer tool bar, click

.

. - In menu bar, click Object → Layer Setting.

Layer Setting dialog box pops up.

See Interface Overview for details.

- In layer tool bar, click

Set general parameters.

See General Parameters for details.

Set layer technics.

See Layer Operations for details.

Interface Overview

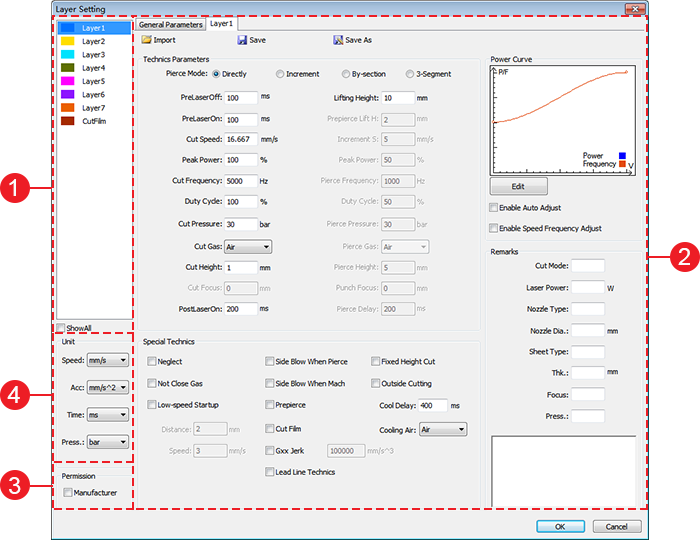

Layer interface is shown as follows:

①: Layer selection area

It is used to do the following:

- To switch to the page of the target layer, click the layer name.

- To modify the layer name, double click the layer name.

- To show all layers, check Show All. Otherwise, the system only shows layers in the current toolpath file.

②: Parameter setting page

It is used to switch between the following pages by clicking switch buttons:

General Parameters page

See General Parameters for details.

Layer number page

You can set cutting and piercing technics for each layer.

See Layer Operations for details.

Layer number-Three Segment Parameters page

If you select 3-Segment in Layer number page, this page appears.

See Set Technic Parameters for details.

Layer number-Lead Line Technic page

If you select Lead Line Technic in Layer number page, this page appears.

It is used to cut thick sheets with the high power. Dreg will be generated during piercing the sheet, and it will weaken effect of height sensing unit.

Setting the lead line parameters will help avoid the dreg at the start point before reaching the cutting height.

See Set Technic Parameters for details.

Layer number-Arris Parameters page

It is exclusive for tube cutting configuration. It shares the same layer with Layer number page.

See Over-arris Parameters for details.

③: Permission setting bar

It is used to set permission by checking Manufacturer, so as to set parameters in Motion Control Parameters and Laser Device Parameters areas in General Parameters page.

See Motion Control Parameters and Laser Device Parameters for details.

④: Unit setting bar

It is used to set unit according to the actual situation.

Layer Operations

Layer operations include the following:

- Set technic parameters.

- Adjust the power curve.

- Add technic remarks.

- Save Layer Technics

- Import technics

After setting layer technics, do one of the following to save the setting:

Click Save. The layer technics are saved into the technic library for backup.

Click Save As. The layer technics are saved as a LTP file.

If you need to use the saved layer technics, click Import to import a LTP file.

Set Technic Parameters

To set technic parameters, do the following:

Select a piercing method.

See Piercing Methods for details.

Set parameters in Technic Parameters and Special Technic areas.

See Layer Technic Parameters for details.

Optional: If your selected piercing method is 3-Segment, set Piercing parameters in Layer number-Arris Parameters page:

Check 1st Segment, 2nd Segment and 3rd Segment. The system executes three-segment piercing from the first to the third.

If any segment is unchecked, the system skips this segment.

Check Increment S and set the parameter.

Increment S: the speed of the cutting head during falling to the cutting height.

If it is unchecked, the cutting head follows to cutting height.

Check Extra Blow and set Delay and Pressure. The system executes blowing without laser on after piercing.

If Extra Blow is unchecked, the system executes blowing with laser on after piercing.

Optional: If you select Lead Line Technic, set parameters in Layer number-Lead Line Technic page:

Check Fall Slowly and set the related parameters.

The cutting head starts falling slowly from Lead Line Height to Cutting height at the Speed and cuts the lead line.

Check Circle and set the related parameters if there is a circle at the start point of the lead line.

See Special technic parameters for details.

Note: When Lead Line Technic and Low-speed Startup are checked at the same time, and there are lead lines in the toolpath, low-speed startup technics cannot take effect.

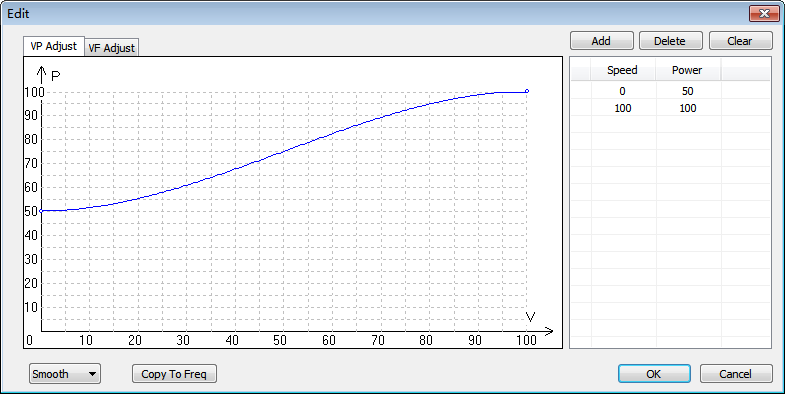

Adjust the Power/Frequency Curve

This operation is used to make the cutting power and frequency change with speed accordingly and ensure thermal power absorbed in unit area is the same and achieve fine cutting result, so as to solve problems like over-burning around the corner and difference of cutting result in terms of thickness.

Before adjusting the curve, check Enable Auto Adjust in Power Curve area. The system automatically adjusts the speed to the power or frequency based on the curve without other manual operations. Otherwise, the power or frequency remains the same.

To adjust the power curve or the frequency curve in Power Curve area, do the following:

Click Edit. Edit dialog box pops up:

Do one of the following:

Adjust the power curve or the frequency curve on the curve:

- To add a node, double click the target position.

- To delete a node, double click the target node.

- To modify a node, double click the target position over/under the node.

Corresponding speed and power values are added/deleted/modified in the right table synchronously.

Adjust the power curve or the frequency curve with buttons:

To switch between the curve and the straight line, select Smooth or Linear.

To copy the frequency curve or the power curve, click Copy To Freq or Copy To Power.

Adjust the power curve or the frequency curve by editing in the table:

- To add a group of speed and power values, click Add, and double click to modify the values.

- To delete a group of speed and power values, select the values and click Delete.

- To modify a group of speed and power values, double click and modify the values.

Corresponding node is added/deleted/modified on the left curve at the same time.

The more nodes are added, the more precise the curve is.

If you need to restore the curve to default, click Clear.

Add Technic Remarks

This operation is used to make notes for machining information, so that the system automatically generates name of the technic file when you save layer technics.

To add technic remark, enter remark information in Remarks area.

Save Layer Technics

To save layer technics, do one of the following:

Click Save. The layer technics are saved into the technic library for backup.

Click Save As. The layer technics are saved as a LTP file.

The default save path differs in software installation:

If you put generated files and executed files separately, the default save path is as follows:

D:\Weihong\TechnicLibraryIf you do not put generated files and executed files separately, the default save path is as follows:

C:\ProgramFiles(x86)\Weihong\TechnicLibrary

The file name is automatically generated according to the technic remark. Its format is as follows:

XX W (Laser Power) + XXX (Sheet Type) + XX mm (Sheet Thickness) + XX (Nozzle Type) + XX (Nozzle Diameter) + F XX (Focus) +P XX(Pressure).

For example, ltp2000W CS 2mm S0.5 F-0.5 P0.5.ltp

If you want to use the existing technics, see Import Technics for details.

Import Technics

This operation is used to import existing technics and technics.

To import the technics, do the following:

In the layer tool bar,click

. Layer dialog box pops up:

. Layer dialog box pops up:In Layer-number page, click Import.

Optional: Click Add to add external files to the technics library.

Select a type and thickness of material and click Search.

Optional: To preview its technic remark in Preview area, click on the ITP file.

Select the ITP file and click Open.

The technics file is imported and opened.

Piercing Methods

Piercing methods include the following:

Direct Piercing

The system automatically executes direct piercing as follows:

Turn on follow valve and blow valve.

Control the cutting head to follow up until it reaches the cutting height and wait for blow delay time.

Turn on laser valve and start machining.

Increment Piercing

The system automatically executes increment piercing as follows:

Turn on follow valve and blow valve.

Control the cutting head to follow up until it reaches the cutting height and wait for blow delay time.

Turn on laser valve and execute piercing for piercing delay time.

Keep laser valve on, control the cutting head to fall to the cutting height at increment speed and start machining.

Segment Piercing

The system automatically executes segment piercing as follows:

Turn on follow valve and blow valve.

Control the cutting head to follow up until it reaches the piercing height and wait for blow delay time.

Turn on laser valve and execute piercing for piercing delay time.

Turn off laser valve and control the cutting head to follow up until it reaches the cutting height.

Turn on laser valve and start machining.

Three-segment Piercing

Three-segment piercing is divided into three segments and used to cut thick materials.

According to the checked three-segment method, the system executes piercing by falling the cutting head to the piercing height from the first to the third. See step 3 of Set Technic Parameters for details.

General Parameters

This section introduces general parameters that can be set by users.

General parameters include the following:

- Motion control parameters

- Laser device parameters

- Burst parameters

- Follow control parameters

- Post-task actions parameters

- Advanced function parameters

Motion Control Parameters

Frame Speed

- Default speed during cutting frame.

- Range: [0, Maximum value among the maximum speed values of all axes]mm/min

- Default value: 30000

G00 Speed

- Default speed during locating.

- Range: [0, Minimum value among the maximum speed values of all axes]mm/min

- Default value: 30000

- Set G00 speed for each axis in G00 Speed(X) and G00 Speed(Y) input boxes which appear after Set rapid traverse parameters separately is checked.

Laser Device Parameters

Reset Laser

- The laser device must be reset to return to normal status after alarms in laser device are removed.

Burst Parameters

Peak Power

- Laser intensity during executing burst.

Frequency

- Frequency of light output by pulse during executing burst.

Duty Cycle

- In per unit pulse cycle, the ratio of light output time to the unit pulse cycle time.

Time

- Duration of laser during executing burst.

Follow Control Parameters

Leaping Min. Dis

- When the distance is smaller than the value, the system directly traverses to the start point of the next object without frog leaping and uplifting the cutting head.

Fixed Pos

- A fixed height of Z-axis.

- You can either click Get Fixed Pos to set current Z-axis machine coordinate as the fixed position or directly enter the height manually.

Direct Follow Height

- If follow height and height for three-segment piercing are less than the value, the cutting head directly follows to the set height.

- If follow height and height for three-segment piercing are greater than the value, the cutting head follows 1mm and rises to the set height.

Post-task Actions Parameters

Z Up Position

- The target position to which the cutting head rises after machining.

XY Axes

- Actions of X-axis and Y-axis after machining.

Advanced Function Parameters

Cut Film

- Used to solve the problem that film on metal material is melted and stuck to the cutting head and the sheet during cutting coated metal material.

- Methods of film cut include the following:

- Cut single: cut film before machining a single object.

- Cut group: cut film before machining a group of objects and then execute the same operation to other groups.

- Generally, default values of machining parameters of cutting film like power and cutting height are different from actual machining parameters. You need to set them according to actual situation. You can set proper cutting film parameters in Cut Film layer.

Outside Cut Height

- The distance between the cutting head and the material surface during leading in from outside material.

- After setting the height, click Set Outside Height to confirm.

Layer Technic Parameters

Layer technic parameters include the following:

- Cutting parameters

- Piercing parameters

- Delay parameters

- Uplifting parameters

- Special technic parameters

- Over-arris parameters

Cutting Parameters

Cut Speed

- The cutting speed when feedrate override is 100%.

Peak Power

- The laser intensity during cutting when the laser device is adjusted via the analog quantity.

Cut Frequency

- The carrier frequency of PWM modulate signals during cutting, namely the light output times in one second.

- The larger the value is, the longer light output time is.

Duty Cycle

- In per unit pulse cycle, the ratio of light output time to the unit pulse cycle time.

- You can set it bt adjusting the laser device via PWM to set duty cycle during cutting setting.

Cut Pressure

- The auxiliary gas pressure during cutting.

- It should be used together with proportional valve or multi-valve.

Cut Gas

- The type of auxiliary gas used during cutting.

Cut Height

- The distance between the nozzle and the material during cutting.

Cut Focus

- The position of focus during cutting.

- It takes effect after enabling focus control.

- See Control Focus for details.

Piercing Parameters

Increment S

- The speed of the cutting head during falling from the piercing height to the cutting height during increment piercing.

Peak Power

- The laser intensity during cutting when the laser device is adjusted via the analog quantity.

Pierce Frequency

- The carrier frequency of PWM modulate signals during piercing.

- In general, it is set relatively lower and pulse is used to avoid bad piercing.

Duty Cycle

- In per unit pulse cycle, the ratio of light output time to the unit pulse cycle time.

- You can adjust the laser device via PWM to set duty cycle during piercing.

Pierce Pressure

- The pressure of auxiliary gas during piercing.

- It should be used together with proportional valve or multi-valve.

Pierce Gas

- The used auxiliary gas during piercing.

Pierce Height

- The distance between the piercing position and the material.

Punch Focus

- The position of focus during piercing.

- It takes effect after enabling focus control.

- See Control Focus for details.

Pierce Delay

- The duration of laser on at piercing height during increment piercing and segment piercing.

Note: In Layer number-Three Segment Parameters page, Pierce in names of all parameters is omitted.

Delay Parameters

Pre-laser Off Delay

- The delay time before the laser is turned off.

Pre-laser On Delay

- The delay time before the laser is turned on.

Post-laser On Delay

- After the laser is turned on, the system lasts the set time before the next step.

Uplifting Parameters

Lifting Height

- The uplifting distance of the cutting head after cutting each object.

Pre-pierce Lift H

- The uplifting distance of the cutting head after piercing each hole during preliminary piercing.

Special Technic Parameters

Neglect

- Not machine all the objects in the current layer.

Not Close Gas

- Not close port Blow during cutting all the objects of the current layer.

Low-speed Start up

- Used to confirm the cutting quality during cutting a thick plate.

- With it enabled, the system cuts a start distance long aperture at start speed, so that the gas can be blown into the aperture. Then cut at normal speed.

- After enabling it, you need to enter the distance and speed to start.

Side Blow When Pierce

- Used to open port Side Blow during piercing.

Side Blow When Mach

- Used to open port Side Blow during machining.

Prepierce

- Pre-piercing function is valid for all the objects of the current layer.

- It is recommended to select method Increment Piercing or Segment Piercing.

Fixed Height Cut

- Used to cut material at a fixed height.

- You can get a fixed position or manually input the fixed position height to set it.

Outside Cutting

- Used to cut sheet directly from the outside without piercing it.

- It mainly used in cutting thick sheets or parts with high precision.

Cool Delay

- Blowing time at cooling point.

Cooling Air

- The used gas during blowing.

Stable Distance

- The distance of cutting the lead line on the cutting height.

- Stable Distance = Lead Line Length - Slowly Falling Distance

- If its value is greater than the lead line length, the default formula is as follows:

Stable Distance = Lead Line Length - 3mm

Lead Line Height

- The height that Z-axis starts falling down.

Lead line Circle Speed

- The speed of cutting the circle at the start point of the lead line.

Over-arris Parameters

Setting over-arris parameters is used to avoid over-burning from uneven distribution of laser energy on faces and arrises during cutting a rectangular tube.

In cutting a rectangular tube, rotation of the tube causes the uneven distribution of laser energy on faces and arrises. Then over burning occurs. Setting over-arris parameters is used to solve the problem.

Peak Power

- Used to set peak current during over-arris cutting by adjust the laser device via the analog quantity.

Air Pressure

- The pressure ofauxiliary gas during over-arris cutting.

- It should be used together with proportional valve or multi-valve.

Cut Frequency

- The carrier frequency of PWM modulate signals during over-arris cutting, namely the light emission times in one second.

Over-arris Height

- The distance between the nozzle and the material during over-arris cutting.

Duty Cycle

- In per unit pulse cycle, the ratio of light output time to the unit pulse cycle time.

Sensitivity

- The sensitivity of the cutting head during over-arris cutting.

Over-arris Speed

- The cutting speed during over-arris cutting.