Use Device Maintenance

This operation is used to maintain or manage wearing parts and tools, and monitor tools.

It includes the following:

Manage Wearing Parts

This operation is used to manage all wearing parts and replace them in time.

To manage the wearing parts, do the following:

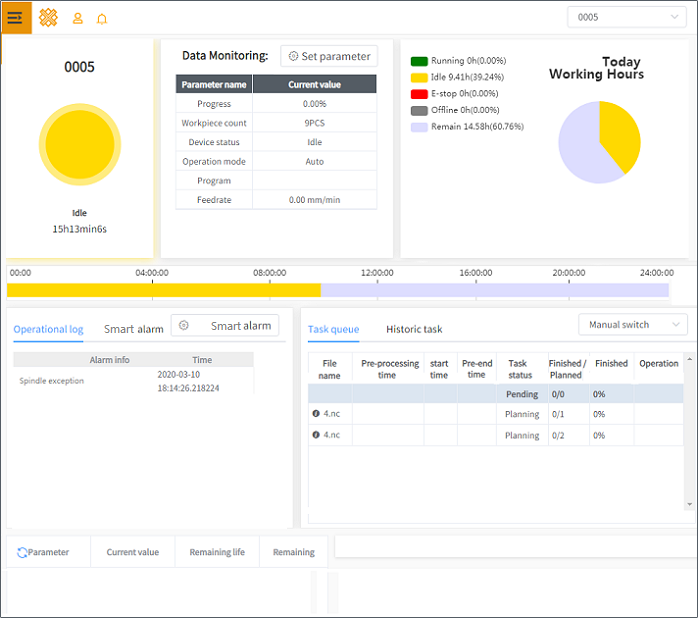

To enter Device Monitoring interface, click

→ Device Management → Device Monitoring.

→ Device Management → Device Monitoring.Select the target single machine tool in the upper right corner:

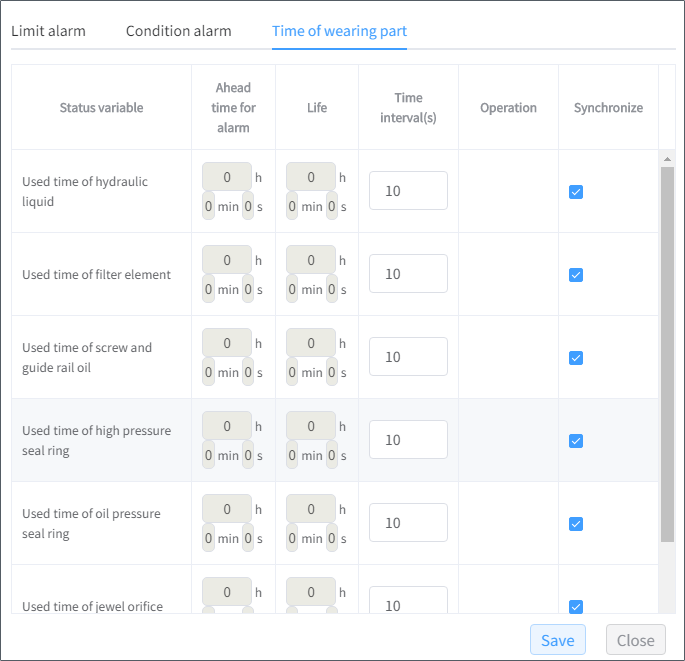

Click Smart alarm in the message area and click Time of wearing part:

Set the following for wearing parts of the target device:

- Time for alarms in advance

- Service life

- Interval(s)

If a wearing part runs out of service life or reaches the time for the alarm in advance, a prompt pops up in the upper right corner at the set interval.

Optional: Check Synchronize. When the target CNC system updates the data of wearing parts, xFactory updates the data at the same time.

Check the used time and remaining service life in the maintenance area of Device Monitoring interface.

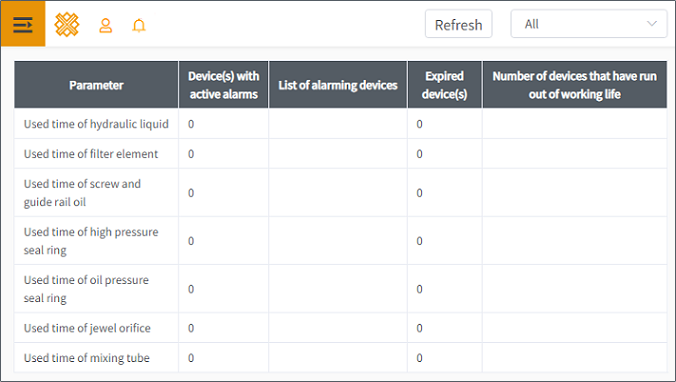

To check all machine tools whose wearing parts have run out of their life and reached the time for alarms in advance, click

→ Device Management → Wearing Parts:

→ Device Management → Wearing Parts:

Manage Tools

This operation is used to manage all tools, including setting alarms for tools , recording and accumulating the total usage time of tools on the different machine tools.

To manage tools, do the following:

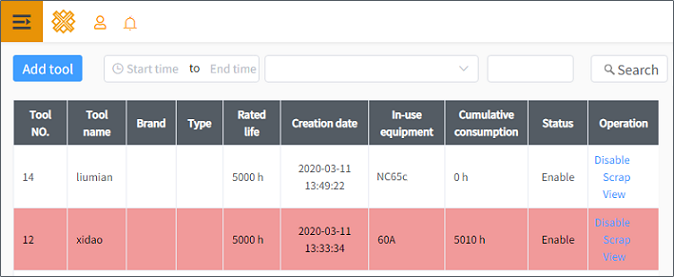

To enter Tool Manager interface, click

→ Device Management → Tool Manager:

→ Device Management → Tool Manager:

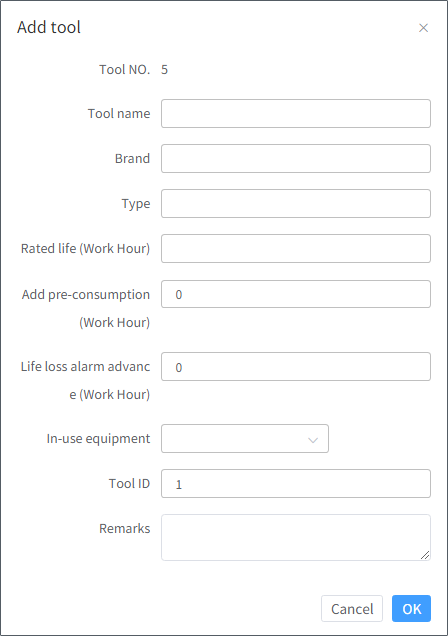

To add tools, click Add tool and do related settings:

To check tool records, set the search conditions and click Search.

For tools that have run out of their life, rows of their records become red.

Optional: To enable/disable/scrap the target tool, click Enable / Disable / Scrap in Operation column.

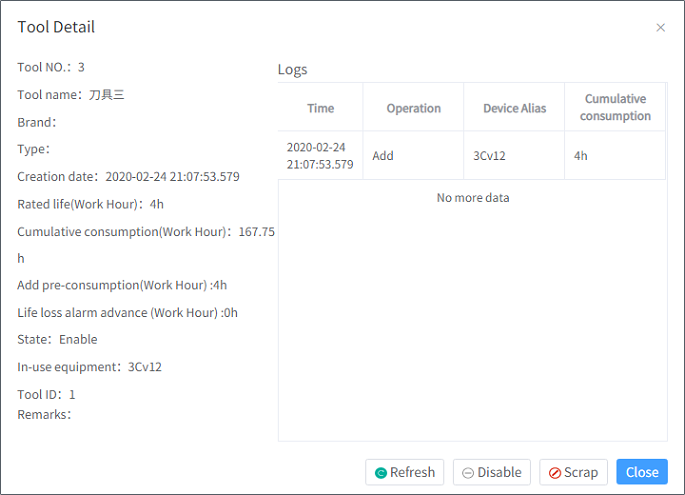

Optional: To check details about the target tool, click View in Operation column. Tool Detail dialog box pops up:

Monitor Tools of Spindles

This operation is used to set tools of spindles and check its status according to the warnings and alarms.

To monitor tools of spindles, do the following:

To enter Tool Monitoring interface, click

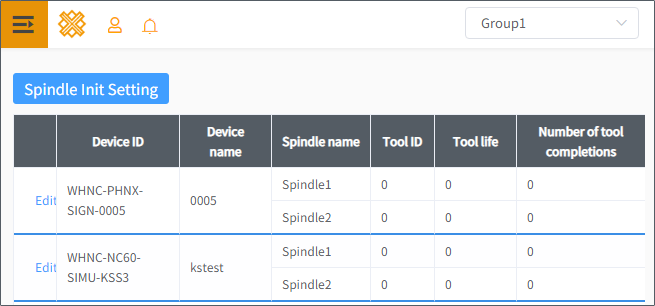

→ Device Management → Tool Monitoring:

→ Device Management → Tool Monitoring:

Optional: To check monitored tools within a group, select the target group in the upper right corner.

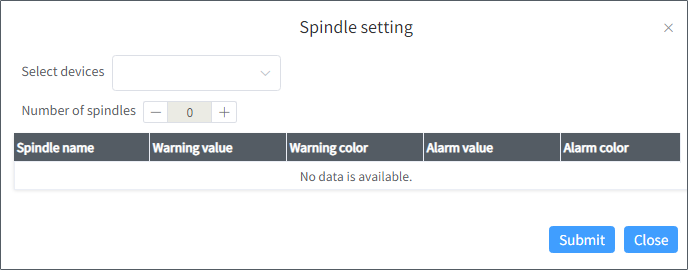

Click Spindle Init Setting. Spindle setting dialog box pops up:

Select a machine tool or more.

Set the quantity of spindles.

The maximum quantity is 5.

To set warnings and alarms, set warning values, warning colors, alarm values and alarm colors.

Click Submit.

When the number of finished workpiece that the tool can machine reaches the value of warning and alarm, the warning and alarm occur with the warning color and alarm color.

After setting tools of spindles, to modify their settings, click Edit in Tool Monitoring interface and modify settings.