System Management

This section introduces system-related operations in the NcStudio Phoenix Nine Axis Six-Side Drilling System.

The operations below are available in the Process or Control screen.

Create an Installation Package

You can create an installation package with the current system data for system file backup and keeping a copy of a stable system version.

Procedures:

In the menu bar, go to File > Generate Installation Package.

In the displayed Packup Tool dialog box, click Browse to select a storage path for the installation package.

Click Pack up to make the system start generating an installation package.

After an installation package is generated, you can find it under the selected directory.

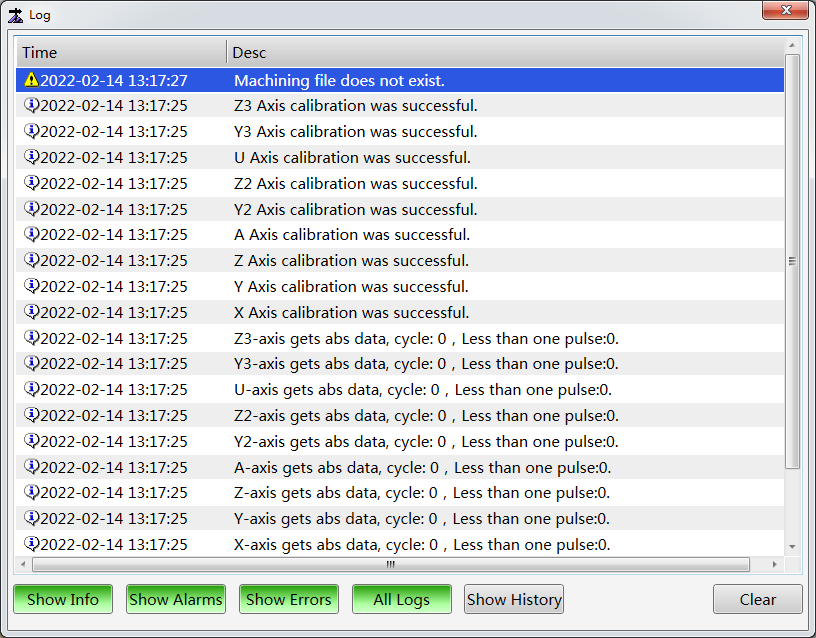

View the Log

The system log shows important user operations, and system events and time after current system boot and in history.

Procedures:

Use one of the following methods to view the log:

- In the status bar, double-click the blank area/warning message.

- In the menu bar, go to System > Log.

In the Log dialog box, all information after current system boot is displayed by default.

Highlight the corresponding button based on the type of log you want to check:

- Software running information (

): Click Show Info.

): Click Show Info. - Alarms (

): Click Show Alarms.

): Click Show Alarms. - Errors (

): Click Show Errors.

): Click Show Errors. - All logs after current system boot: Click All Logs.

- All logs since the software is installed: Click Show History.

- Software running information (

(Optional): To delete all log information, click Clear.

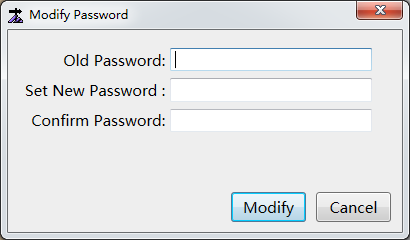

Change the Password

The manufacturer password is required to edit drills, view/modify global manufacturer parameters, and set datum.

Procedures:

In the menu bar, go to System > Change Password.

In the displayed Modify Password dialog box, enter the old password and new password.

Click Modify.

Back up and Restore CNC Parameter Settings

You can back up the machining parameter settings and import the backup data later if needed.

Procedures:

In the menu bar, go to System > Recover Parameter Backup.

- Click Backup to save the settings as an XML file in the directory D:\Weihong\XML.

- To import a backup file, select it and click Restore.

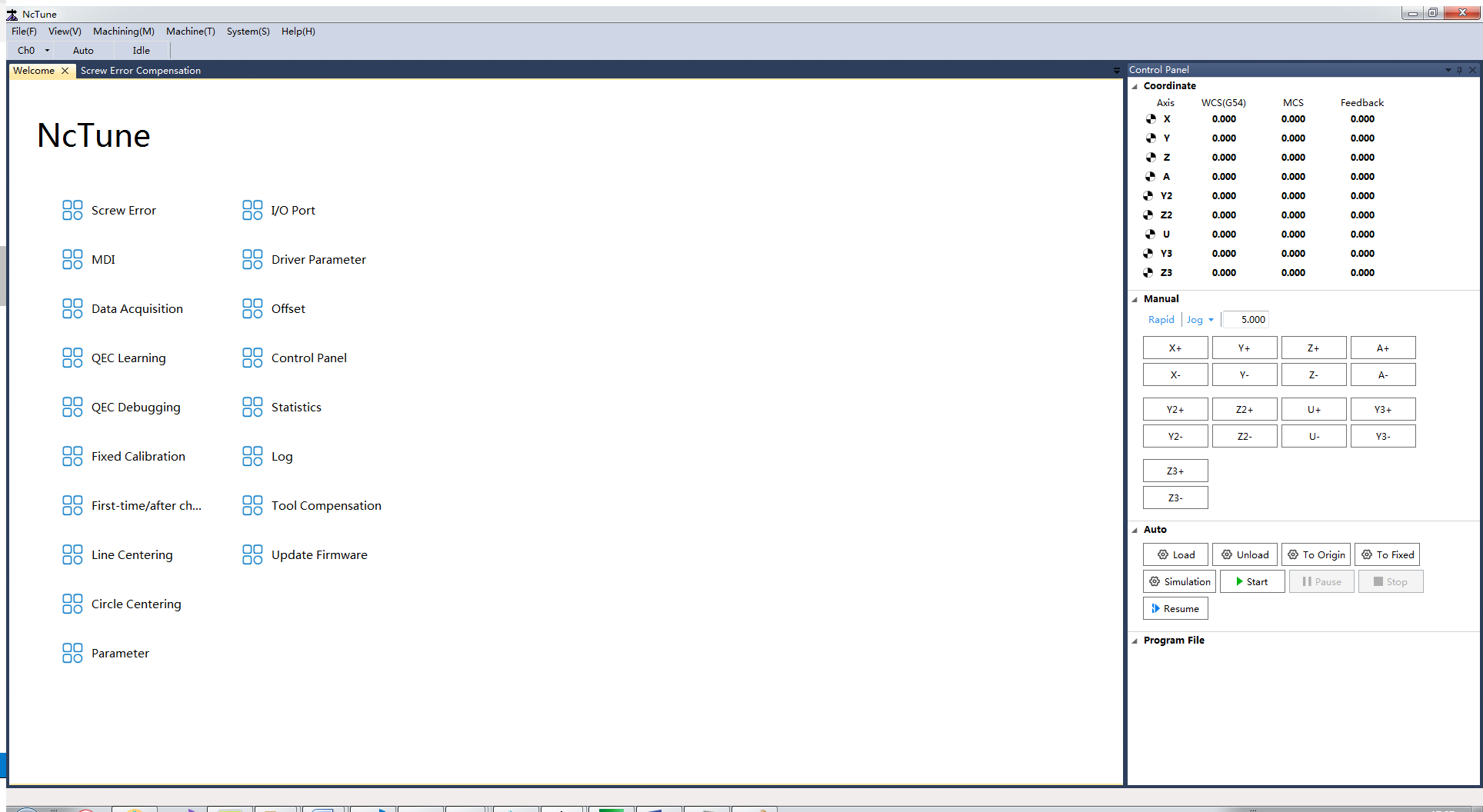

NcTune

NcTune includes functions that are not required during machining but may be needed during machine debugging.

In NcTune, you can use functions of lead screw error compensation, tool calibration, modifying port polarity, viewing the log, using MDI, setting drive parameters, setting tool compensation parameters, collecting data, centering, setting offset, using the control panel, updating firmware, setting system parameters, and viewing machining statistics data.

Use one of the following methods to show the NcTune page:

In the menu bar of NcStudio, go to System > NcTune.

Close NcStudio. Open the following directory, and find and double-click NcTune.exe:

C:\Program Files\Weihong\NcStudio\Bin

For details about machine debugging, see Machine Debugging.

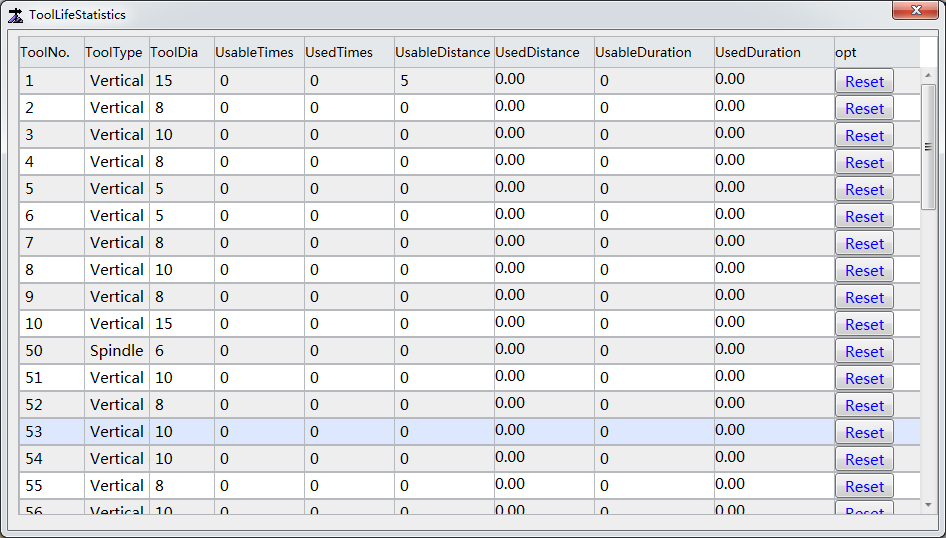

Check Tool Lifespan

You can check the tool lifespan to replace old tools in time, manually clear tool wearing data and define the tool lifespan.

Procedures:

In the menu bar, go to System > ToolLifeStatistics.

The UsableTimes, UsableDistance, and UsableDuration fields of the tools can be modified.

The UsedTimes, UsedDistance, and UsedDuration fields show the automatically collected data.

(Optional): If a tool has reached the set usable times/distance/duration and is replaced, you need to click Reset to clear the old data.

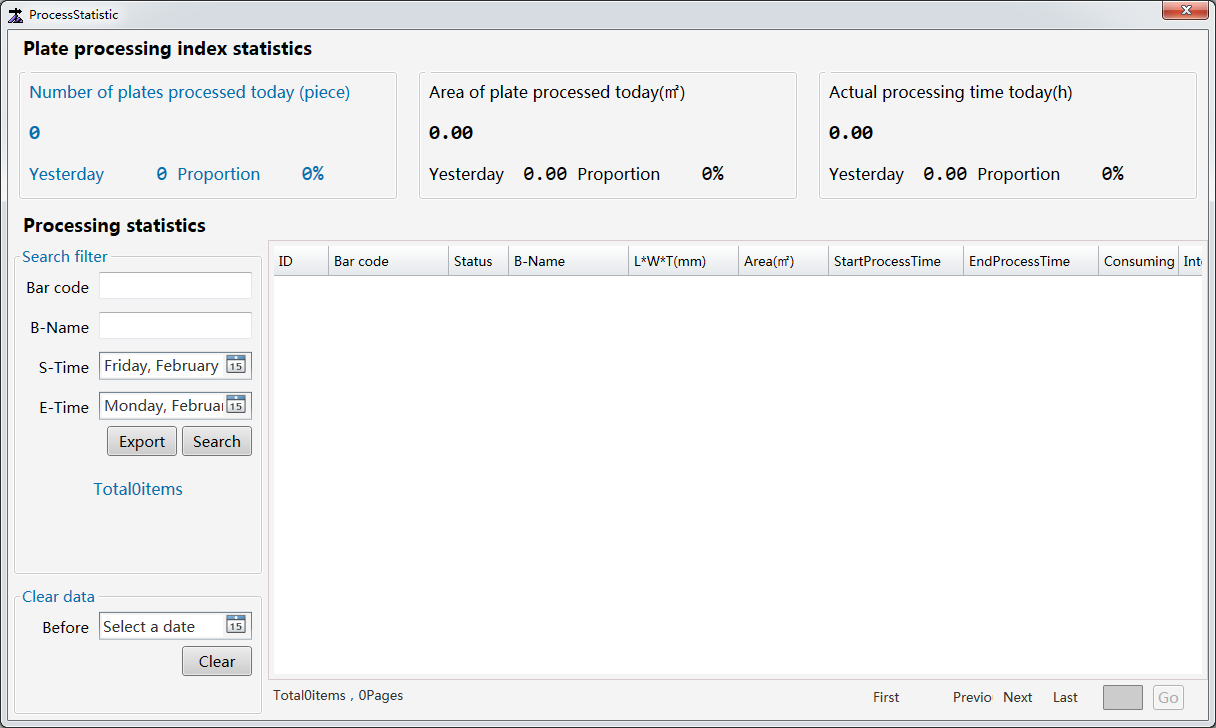

View Machining Statistics

The system records the number of boards and the board area processed, the machining duration, and compares those with yesterday's data.

On the statistics page, you can check the board size, machining duration, and the number of holes and slots.

Procedures:

In the menu bar, go to System > ProcessStatistic.

In the ProcessStatistic dialog box, enter the board bar code, name, and machining start and end time, and click Search to search for machining records that meet the conditions.

(Optional): To clear machining data, specify a date in the Clear data area and click Clear. Machining data before the specified date will be erased.

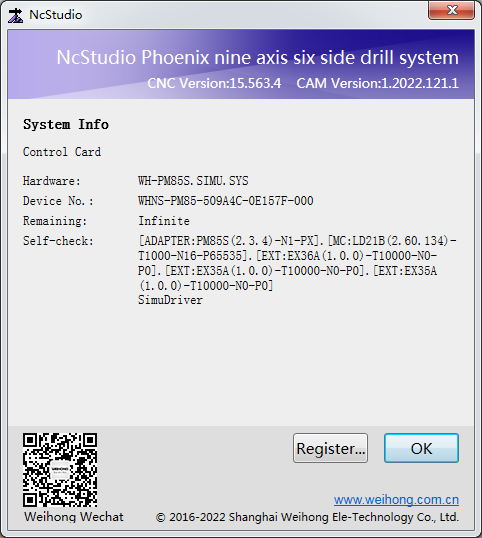

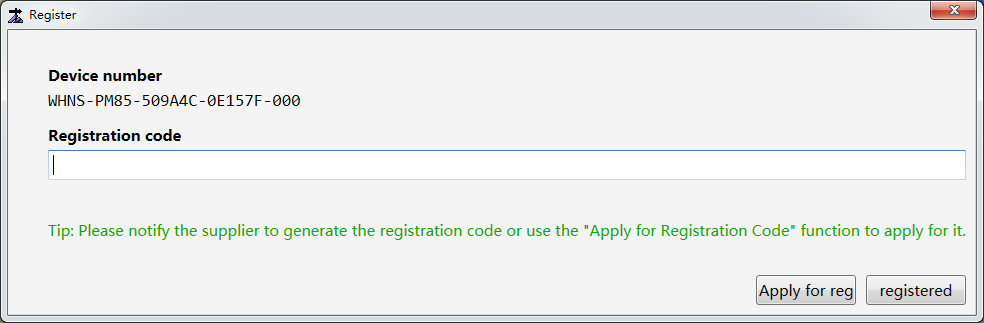

Register the Software

You need to register the software if the software use period has or is about to expire, or if the writing type does not match.

Procedures:

In the menu bar, go to Help > About.

Click Register.

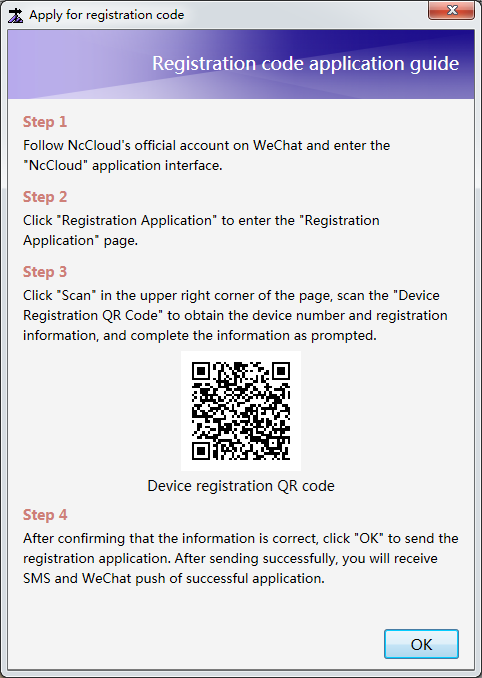

Use one of the following methods to acquire the registration code:

- Send the device number to the machine manufacturer and get a registration code.

- Click Apply for reg, follow the instructions, and click OK.

Enter the registration code in the field. Click registered.

Edit Start and End Codes

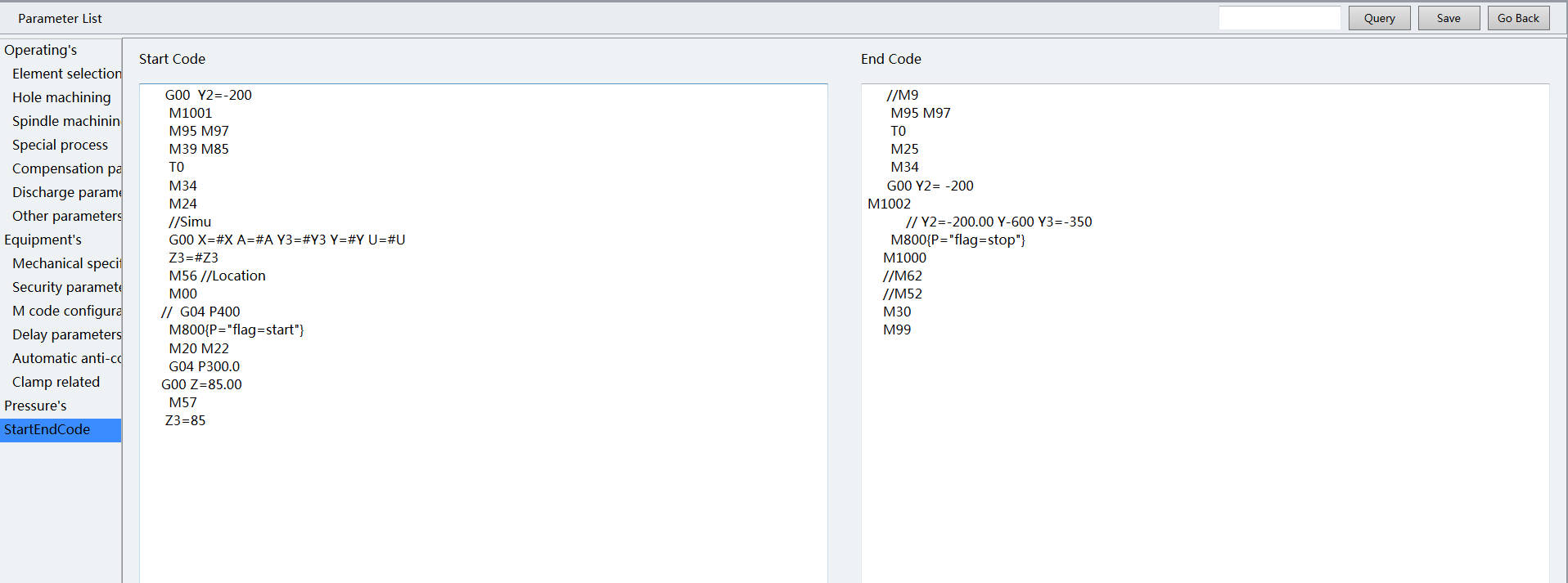

You can edit the start and end codes (supporting M codes) to change the machine movements before and after machining.

Procedures:

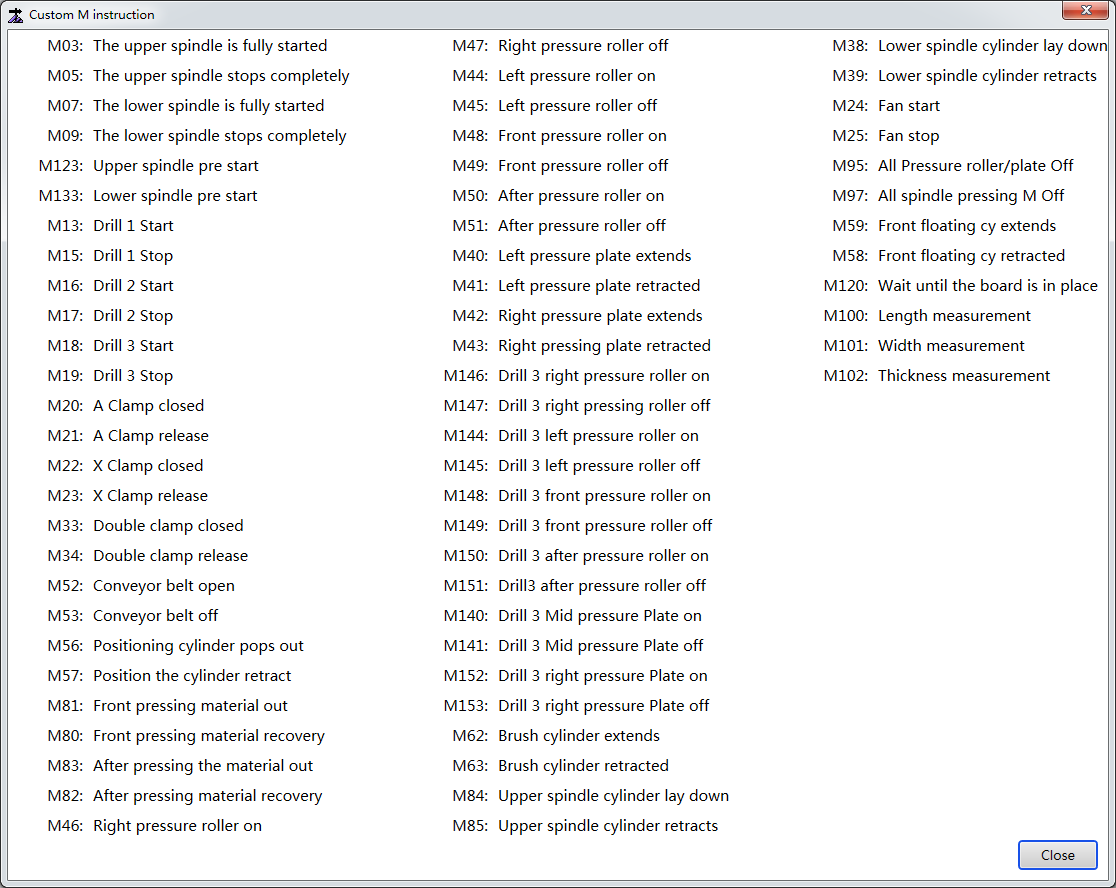

(Optional): To check the definitions of M codes, go to System > Custom M instruction in the menu bar:

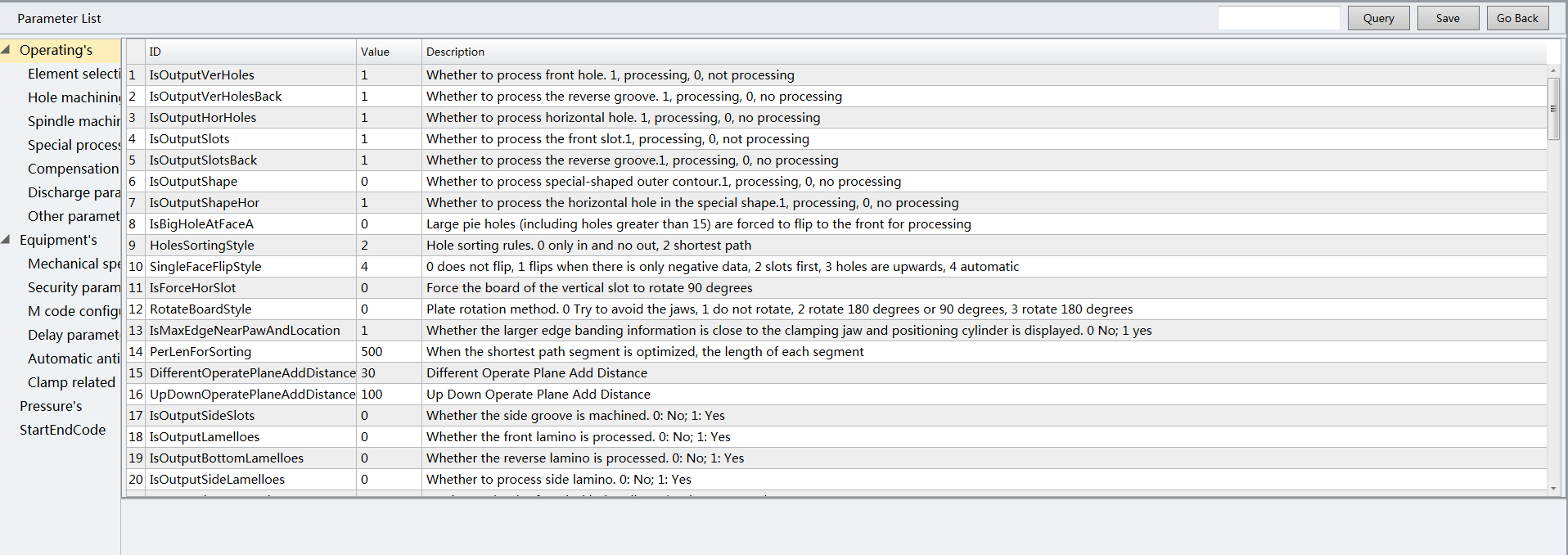

In the NcStudio home page, select the Process screen in the upper right corner. Click the CAM Parameter button above the drawing area.

In the displayed Parameter List window, click StartEndCode in the left list:

Modify the codes based on your needs.