Basic Commissioning

Through this section, you can quickly know the basic commissioning processes of NK105.

To do basic commissioning, do the following:

- Start the system.

- Select the axis mode. (General NK105 with double Z axes)

- Activate the axis. (General NK105 with double Z axes)

- Adjust the port polarity.

- Set pulse equivalent.

- Adjust the axis direction.

- Set the workbench travel.

- Set the machine origin.

- Set the spindle.

If the modification to parameters requires the manufacturer password, please contact us.

Note: Symbol

*before a parameter means the modification requires restarting the system; No Symbol*means the modification immediately takes effect.

Start the System

Power on and start the system. The prompt Back to REF. point? appears:

If you want to return to the machine origin, press

.

.If not, press

.

.

Select the Axis Mode

This operation is applicable to general NK105 with double Z axes.

The axis mode includes the following:

Alternative mode: You cannot activate Z1-axis and Z2-axis at the same time.

Linkage mode: You can activate Z1-axis and Z2-axis at the same time.

To select the axis mode, do the following:

To enter the interface for selecting the axis mode, press

+

+  .

.To select the target mode, press

/

/  →

→  . The selection immediately takes effect.

. The selection immediately takes effect.

Activate the Axis

This operation is applicable to general NK105 with double Z axes. Z1-axis and Z2-axis are activated at the same time by default.

To activate the axis, do the following:

To enter the interface for activating the axis, press

+

+  .

.To select the target axis, press

/

/  →

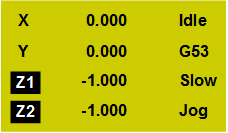

→  . This screen automatically turns to the main interface and Z axes lift up (workbench travel-1):

. This screen automatically turns to the main interface and Z axes lift up (workbench travel-1):

The axis with a black background is activated.

Adjust the Port Polarity

The polarities of input / output ports in the software are specified in terms of the switch type:

- P: Normally closed switches.

- N: Normally open switches.

To adjust the port polarity, do the following:

To enter the menu interface, press

.

.To enter the diagnosis interface, select 8. Diagnosis by pressing

/

/  , and press

, and press  .

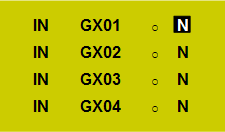

.To check the port polarity, select 2. Port List by pressing

/

/  , and press

, and press  :

:

To modify the port polarity for the target port, select the target port by pressing

/

/  , and press

, and press  →

→  .

.

Set Pulse Equivalent

During commissioning, you need to modify pulse equivalent according to the actual situation first before controlling the machine tool.

To set pulse equivalent, do the following:

To enter the menu interface, press

.

.To enter the interface of manufacturer parameters, select 5. Mfr Param by pressing

/

/  , and press

, and press  .

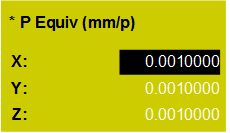

.To check pulse equivalent, select 3. Pulse Equiv. by pressing

/

/  , and press

, and press  :

:

To modify pulse equivalent, input the value with the handheld box and press

. The prompt The parameters are modified. Restart? appears.

. The prompt The parameters are modified. Restart? appears.To validate the modification, press

. NK105 automatically restarts.

. NK105 automatically restarts.

Adjust the Axis Direction

This operation is used to check if the positive direction of each axis is the same with that stipulated by Right Hand Rule, and adjust it if not, so as to avoid damage to the machine tool due to incorrect direction.

Taking X-axis as an example, to adjust the axis direction, do the following:

To enter the menu interface, press

.

.To enter the interface of manufacturer parameters, select 5. Mfr Param by pressing

/

/  , and press

, and press  .

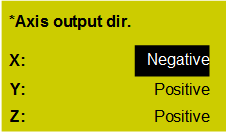

.To check the X-axis direction, select 2. Axis Output Dir by pressing

/

/  , and press

, and press  :

:

According to Right Hand Rule, judge the positive direction of X-axis.

To check if the positive direction of X-axis is the same with the direction stipulated by Right Hand Rule, move X-axis by pressing

/

/  , and observe its moving direction:

, and observe its moving direction:Two directions are the same: The value of parameter Axis Output Direction is correct.

Two directions are opposite: Modify the value of parameter Axis Output Direction to the opposite value.

Set the Workbench Travel

The workbench travel refers to the valid motion range of a machine tool, namely valid machining ranges of all axes.

NK105 sets the upper / lower limit of workbench travel as the soft limit, so the workbench travel needs to be identical with the actual dimension. Otherwise, limit overrun and axis crash may occur. If the machining range specified in the program file exceeds the workbench travel, there will be a prompt box about the soft limit. About handling the soft limit, see Handle the Soft Limit.

To set the workbench travel, do the following:

To enter the menu interface, press

.

.To enter the interface of manufacturer parameters, select 5. Mfr Param by pressing

/

/  , and press

, and press  .

.To check the upper / lower limit of workbench travel, select 4. Machine Stroke by pressing

/

/  , and press

, and press  .

.To set the upper / lower limit of workbench travel, select Strk Upper Lmt or Strk Lower Lmt by pressing

/

/  , and input the target value with the handheld box. The prompt The parameters are modified. Restart? appears.

, and input the target value with the handheld box. The prompt The parameters are modified. Restart? appears.To validate the setting, press

. NK105 automatically restarts.

. NK105 automatically restarts.

Set the Machine Origin

The machine origin, a fixed point, is defined through designing, manufacturing and debugging before the machine tool leaves factory.

To set the machine origin, do the following:

To enter the menu interface, press

.

.To enter the interface of manufacturer parameters, select 5. Mfr Param by pressing

/

/  , and press

, and press  .

.To check the parameters of the machine origin, select 7. REF. Point Set by pressing

/

/  , and press

, and press  .

.

About parameter details, see Machine Origin.

To set these parameters, select REFP Speed / REFP Dir / Retract Dist by pressing

/

/  , and input the value with the handheld box. The prompt The parameters are modified. Restart? appears.

, and input the value with the handheld box. The prompt The parameters are modified. Restart? appears.To validate the setting, press

. NK105 automatically restarts.

. NK105 automatically restarts.

Set the Spindle

This operation is used to set parameters Spindle NO / OFF Delay, Spindle Speed and Maximum Spindle Speed, so as to control the spindle motor.

To set the spindle, do the following:

To enter the menu interface, press

.

.To enter the interface of manufacturer parameters, select 5. Mfr Param by pressing

/

/  , and press

, and press  .

.To check the spindle parameters, select 8. Spindle Set by pressing

/

/  , and press

, and press  .

.

About parameter details, see Spindle.

To set the spindle parameters, select 1. ON / OFF Delay / 2. Spindle Speed / 3. Max Spdl Speed by pressing

/

/  , input the value and press

, input the value and press  .The prompt The parameters are modified. Restart? appears.

.The prompt The parameters are modified. Restart? appears.To validate the setting, press

. NK105 automatically restarts.

. NK105 automatically restarts.