System Overview

NK300CX Integrated CNC System (Hereinafter referred as to NK300CX) consists of hardware and software:

Hardware

Operation panel and keypad panel

- NK300CX-H: WH106C operation panel and WH201C keypad panel

- NK300CX-V: WH108C operation panel

- NK300CX for Frilling: WH208A1 operation panel

Lambda terminal board

It varies with axes configuration and software functions:

- Lambda 4S: pulse-type, up to 4 axes supported.

- Lambda 5S: pulse-type, up to 5 axes supported.

- Lambda 5E: pulse-type, up to 5 axes and absolute function supported.

- Lambda 5M: bus-type, up to 8 axes and absolute function supported.

DB9M/F cables

See NK300CX Connection Diagram for how to connect all hardware.

Software

Based on an embedded platform, NK300CX software can be divided into the following:

- Integral software: combine configurations of 3 axes, 4 axes, and 5 axes as a whole.

- Multi-Z axes software: used for motion control of multi-Z axes, including linkage configuration, double Y linkage configuration and alternative configuration.

This section takes integral software under three-axis configuration as an example.

See Main Software Interface for the introduction for its main software interface.

NK300CX Host

This part introduces the layout and mounting dimension of NK300CX host.

Layout

It introduces the layout of both front view and rear view.

Front View

The front view of NK300CX host is as follows:

USB interface

Used to connect with USB flash disks. And it is protected by a cover.

Display area

Human-machine interface, or user’s interface. It is user-friendly and ease of use.

Functional keys

There are altogether 6 functional areas, including Gen. (machining), Adv. (advanced), Prog. (program), Sys (system), Para. (parameter) and Diag. (diagnosis) keys.

You can access the functional area by directly pressing corresponding key.

Operation keys

Including keys from F1 to F8, and page turning keys.

Used to activate the functions indicated by the soft keys, and turn to previous page or next page.

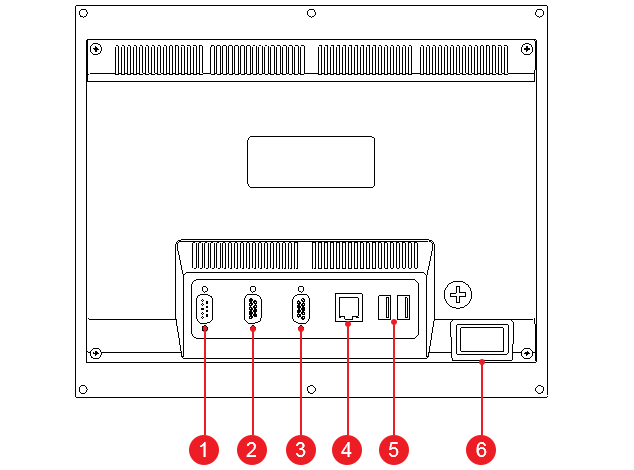

Rear View

The rear view of NK300CX host is as follows:

DB9M/F cable interface

- For NK300CX-H, it is used to connect with the keypad panel.

- For NK300CX-V, it is used to connect with the operation panel.

Terminal board interface

Used to connect with Lambda terminal board.

VGA interface

Used to connect with VGA devices, which are not needed under general situation.

LAN interface

Used to connect with network, with 100Mbps transmission rate.

USB interface

Two USB interfaces, which are used to connect with USB flash disks.

Power interface

Used to connect with 220V power supply.

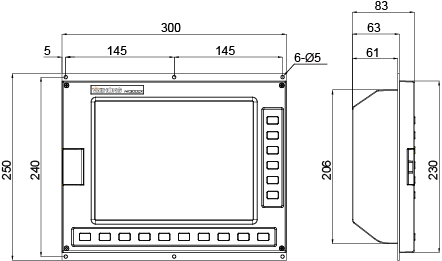

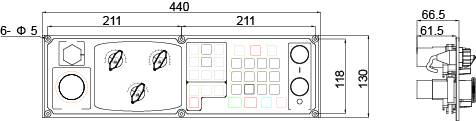

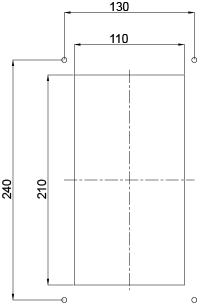

Mounting Dimension (Unit: mm)

NK300CX Dimension

NK300CX Cut-out

WH106C Operation Panel and WH201C Keypad Panel

This part introduces the layout and mounting dimension of WH106C operation panel and WH201C keypad panel used by NK300CX-H.

Operation Panel

This part introduces the layout and mounting dimension of WH106C operation panel.

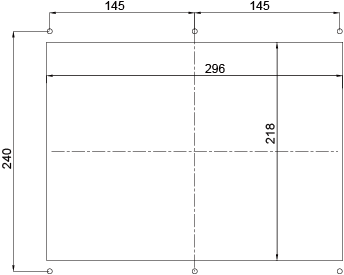

Layout

The front view of the operation panel is as follows:

USB interface

Used to connect with USB flash disks.

E-stop switch

Used to stop the machine tool completely when the machine tool is in danger by triggering the E-stop alarm, so as to protect the operator and machine tool.

After danger is cleared, you can remove the E-stop alarm by rotating the switch in the clockwise direction.

Spindle override knob

Used to adjust spindle override from 50% to 150%.

Keys for mode selection

Used to select a machining mode among Auto, JOG, Handle, Step and REF.Point.

JOG, Handle, Step are referred as Manual mode.

Feed override knob

Used to adjust feed override from 0 to 120%.

Axis direction keys

Used to manually move each axis.

In Manual mode:

- Press an axis direction key and Rapid key. The machine tool moves at rapid jog speed.

- Press an axis direction key. The machine tool moves at jog speed.

Keys for common operations

Used to execute common operations, including Simulate, Single Block, Handle and Reset keys.

Spindle control keys

Used to control spindle movement, including CW, Stop and CCW keys.

Extension keys

Used to customize extension functions, including K1, K2, K3 and K4 keys.

Keys for common ports

Used to turn on or turn off frequently used ports.

Keys for movement control

Used to control the movement of the machine tool, including START, STOP, Pause, and Resume keys.

See Execute Machining for details.

Power Switch

Used to control power on or off.

Mounting Dimension (Unit: mm)

WH106C Dimension

WH106C Cut-out

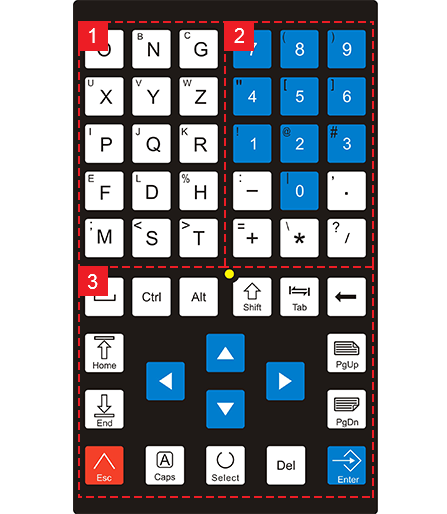

Keypad Panel

This part introduces the layout and mounting dimension of WH201C keypad panel.

Layout

The front view of the keypad panel is as follows:

- Alpha-numeric keys

- Direction keys

- System operation keys

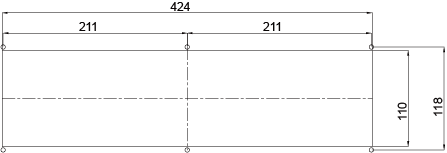

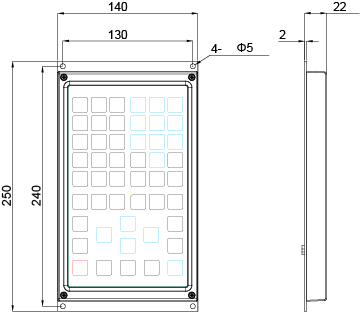

Mounting Dimension (Unit: mm)

WH201C Dimension

WH201C Cut-out

WH108C Operation Panel

This part introduces the layout and mounting dimension of WH108C operation panel used by NK300CX-V.

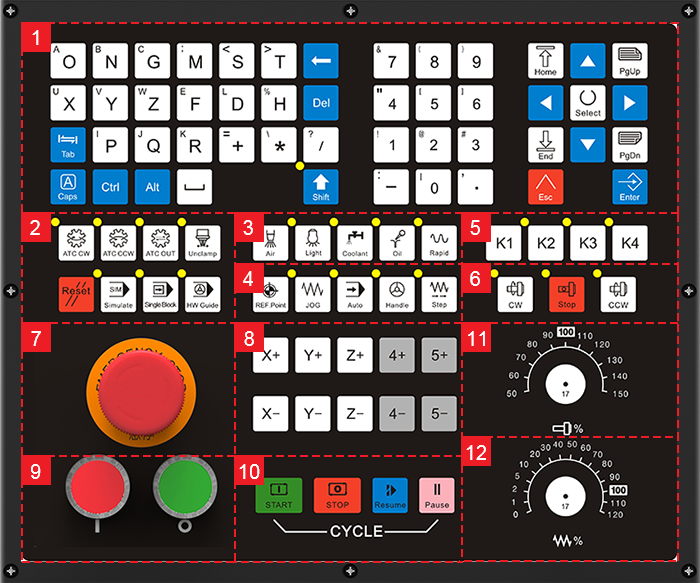

Layout

The front view of the operation panel is as follows:

Alpha-numeric keys

Used to input characters and numbers. Its use is generally the same with that of the computer keyboard:

- Press an alphabet key to enter the alphabet on the right-lower part.

- Press Shift key and an alphabet key to enter the alphabet on the left-upper right.

Keys for common operations

Used to enable frequently used operations, including ATC CW, ATC CCW, ATC OUT, Unclamp, Reset, Simulate, Single Block and HW Guide keys.

Keys for common ports

Used to turn on / off frequently used ports, including Air, Light, Coolant, Oil keys, and control rapid movement, including Rapid key.

Keys for mode selection

Used to select a machining mode among REF.Point, JOG, Auto, Handle and Step.

JOG, Handle, Step are referred as Manual mode.

Extension keys

Used to customize extension functions, including K1, K2, K3 and K4 keys.

In Shoe Machine Control System, K1 key is used as an air brake key for frock clamp. Before each machining, the system will judge whether the fixture is clamped. Only when it is clamped, the system will start machining. Otherwise, a yellow alarm occurs.

Keys for spindle control

Used to control the spindle movement, including CW, Stop and CCW keys.

E-stop switch

Used to stop the movement of the machine tool when the machine tool is in danger, so as to protect the operator and machine tool.

After danger is cleared, you can rotate the switch clockwise to remove the E-stop alarm.

Keys for axis direction

Used to manually move each axis.

In Manual mode:

- Press an axis direction key and Rapid key at the same time. The axis moves at rapid jog speed.

- Press an axis direction key. The axis moves at jog speed.

Power Switch

Used to control power on or off.

Keys for movement control

Used to control the movement of the machine tool, including START, STOP, Pause, and Resume keys.

See Execute Machining for details.

Spindle override knob

Used to adjust spindle override from 50% to 150%.

When parameter N72003 G00 F Fixed is set to No, the knob is used as G00 override knob and used to adjust G00 override from 0 to 100%.

Feed override knob

Used to adjust feed override from 0 to 120%.

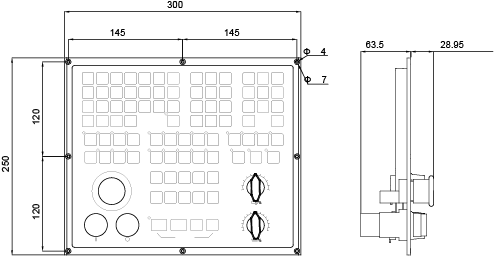

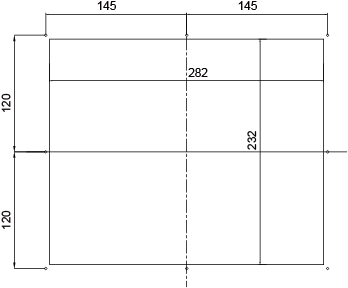

Mounting Dimension (Unit: mm)

WH108C Dimension

WH108C Cut-out

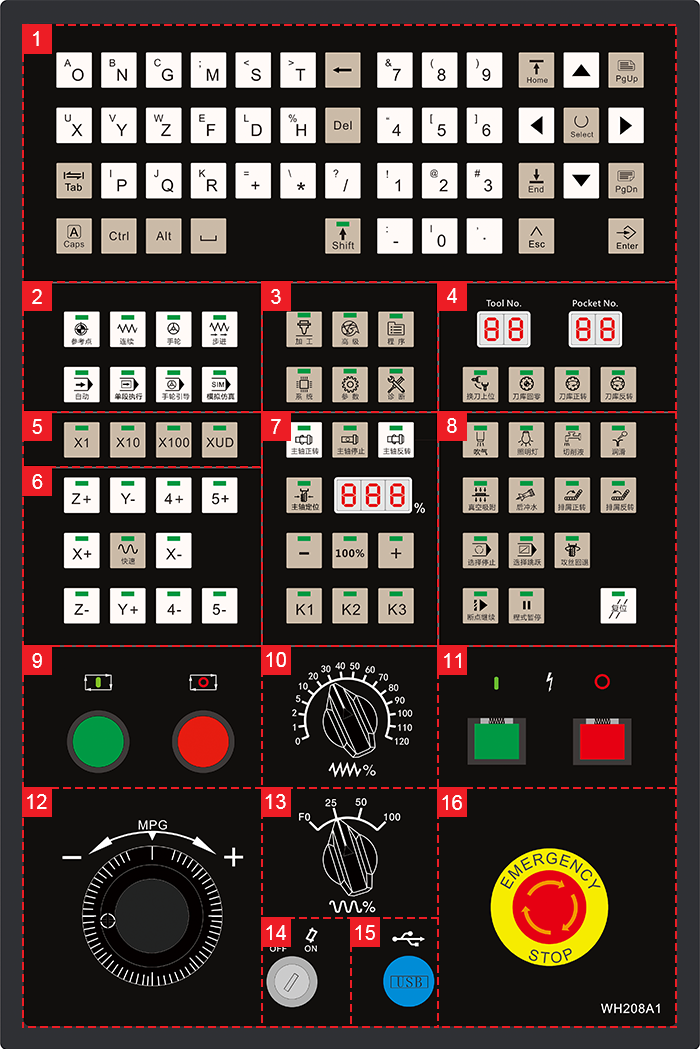

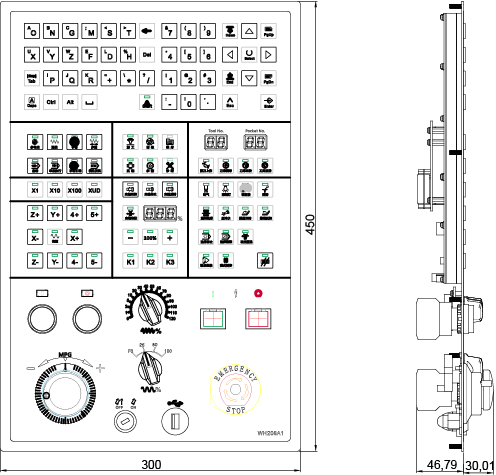

WH208A1 Operation Panel

This part introduces the layout and mounting dimension of WH208A operation panel used by NK300CX for Drilling.

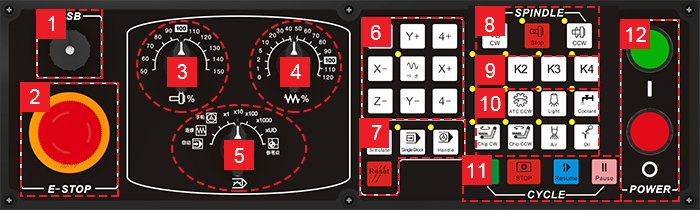

Layout

The front view of the operation panel is as follows:

Alpha-numeric keys

Used to input characters and numbers. Its use is generally the same with that of the computer keyboard:

- Press an alphabet key to enter the alphabet on the right-lower part.

- Press Shift key and an alphabet key to enter the alphabet on the left-upper right.

Keys for mode selection

Used to select a machining mode among Auto, JOG, Handle, Step and REF.Point.

JOG, Handle, Step are referred as Manual mode.

Functional keys

There are altogether 6 functional areas, including Gen. (machining), Adv. (advanced), Prog. (program), Sys (system), Para. (parameter) and Diag. (diagnosis) keys.

You can access the functional area by directly pressing corresponding key.

Keys for tool magazine

Used to check the current tool number, pocket number, and execute operations related to tool magazine.

Note: ATC CW and ACT CCW keys are valid only when Circular Tool Magazine is enabled.

Keys for adjusting step length

Used to adjust step length or override for its own handwheel.

X1, X10, X100 and XUD keys represent 0.001, 0.01, 0.1 and customized step length separately.

Keys for axis direction

Used to manually move each axis.

In Manual mode:

- Press an axis direction key and Rapid key. The machine tool moves at rapid jog speed.

- Press an axis direction key. The machine tool moves at jog speed.

Keys for spindle control

Used to control the spindle movement, including CW, STOP and CCW keys, adjust spindle override, and customize extension function, including K1, K2 and K3 keys.

Keys for common ports

Used to turn on / off frequently used ports, and execute common operations, including Resume, Pause and Reset keys.

Switch for machining control

Used to start or stop the movement of the machine tool.

See Execute Machining for details.

Feed override knob

Used to adjust feed override from 0 to 120%.

Power Switch

Used to control power on or off.

Handwheel

Used to control the movement of the machine tool by a handwheel.

The operation panel has its own handwheel.

G00 override knob

Used to adjust G00 override from 0 to 100%.

Operation panel switch

Used to enable or disable operation panel.

USB interface

Used to connect with USB flash disks.

E-stop switch

Used to stop the movement of the machine tool when the machine tool is in danger, so as to protect the operator and machine tool.

After danger is cleared, you can rotate the switch clockwise to remove the E-stop alarm.

Mounting Dimension (Unit: mm)

WH208A Dimension

WH208A Cut-out

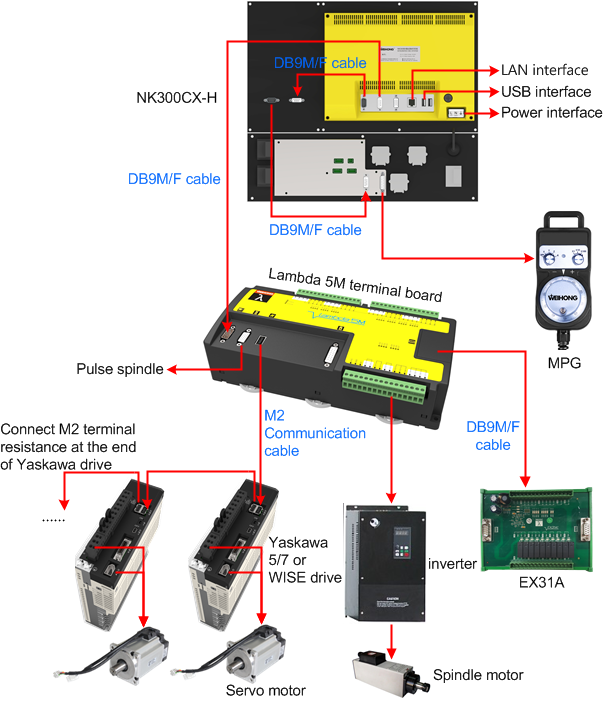

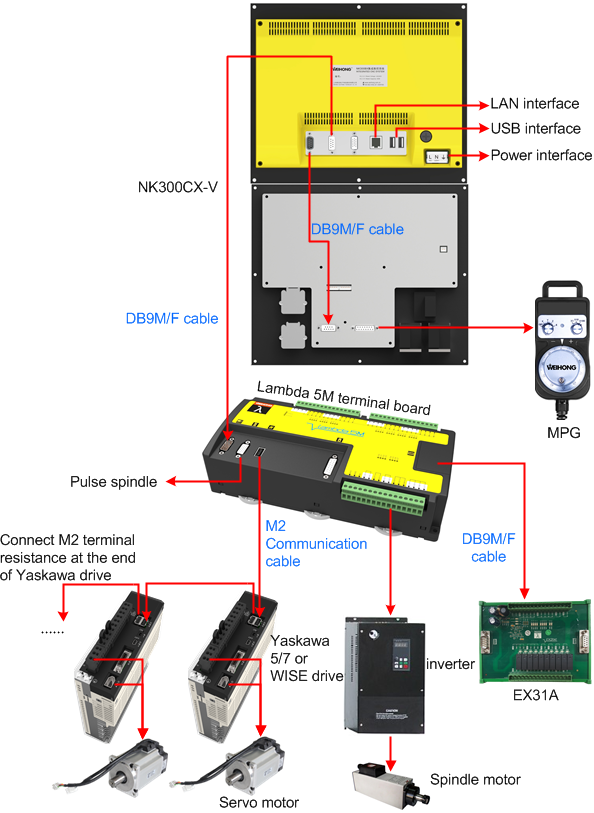

NK300CX Connection Diagram

According to the type of control system, connection diagram of NK300CX can be divided into the following:

- Connection diagram of non-bus control system

- Connection diagram of bus control system

Taking the frequently used bus control system as an example, this part can be divided into the following:

Note: Connection diagram for NK300CX for Drilling bus control system is similar to that of NK300CX-V except its operation panel.

NK300CX-H Connection Diagram

The connection diagram for NK300CX-H bus control system is as follows:

NK300CX-V Connection Diagram

The connection diagram for NK300CX-V bus control system is as follows:

Main Software Interface

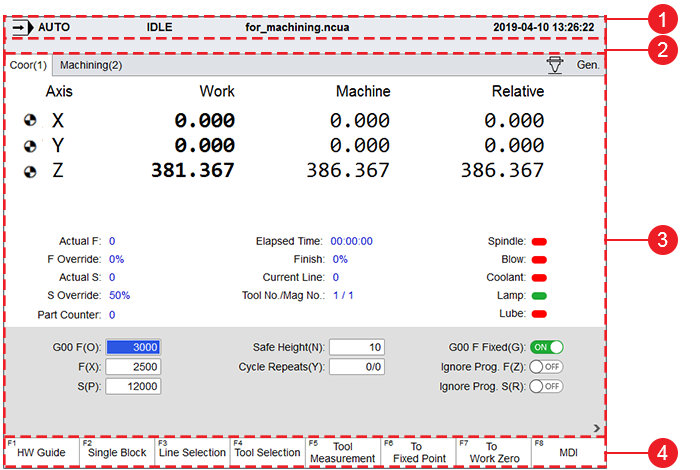

The interactive user interface for NK300CX integral software in AUTO mode is as follows:

Status bar

It shows the following information:

- Current mode, such as Auto, JOG, Step, etc.

- Current status of the machine tool, such as RUN, IDLE, etc.

- Name of the loaded program file.

- Machining time.

Information bar

It shows information, such as machining process, alarms, etc.

Functional area

It shows child interfaces corresponding to each main functional keys.

Functional keys

It show commands corresponding to F1 ~ F8 operation keys.

It differs with the child interfaces.