EMC Installation Guide

Electromagnetic Compatibility(EMC) refers to compatibility of an electrical device that has a good performance in the electromagnetic environment without interfering with other devices.

This guide is intended to help install EMC for NK300CX Integrated CNC System and NK500 Integrated CNC System (hereinafter referred to as NK300CX and NK500). However, please note that although these integrated systems are one of the most important components to control machine tools, they are not the direct target of this guide.

To ensure EMC of machine tools, please note the following:

Note: Interference intensity differs in device, the construction of configuration, control cabinet, wire, etc. And EMC testing of WEIHONG product is conducted based on this book.

Installing a Control Cabinet

It is important to install a control cabinet, so as to ensure EMC of machine tools.

To install a control cabinet, do the following:

Use metal material to make the body and door of the control cabinet.

To connect metal plates for the control cabinet body, do one of the following:

Weld metal plates.

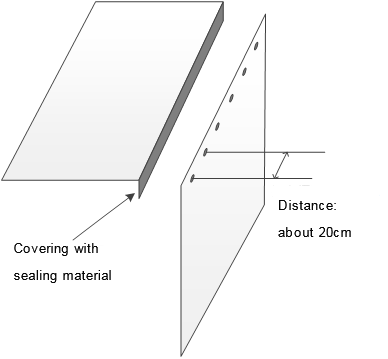

Remove the oil paint at the fixed position, cover the fixed position with sealing material, choose the proper hole distance and fasten metal plates with screws as follows:

Please choose the proper hole distance to ensure the sealing of the control cabinet.

Note: Avoid making the metal plates warped resulting from screwing, etc. Or the sealing of the control cabinet cannot be ensured.

Optional: Cover large openings, such as vent holes.

To connect the control cabinet door to its body, do one of the following:

Extend their contact area, and then screw the control cabinet door and its body.

Correctly place EMI shielding gaskets or conductive gaskets, evenly make them contact with metal surface, and then screw the control cabinet door and its body.

If you choose other ways, please ground the control cabinet door to reduce its impedance.

Install an interference filter.

Wiring and Grounding

It is important to correctly wire and ground the following, so as to ensure EMC of machine tools.

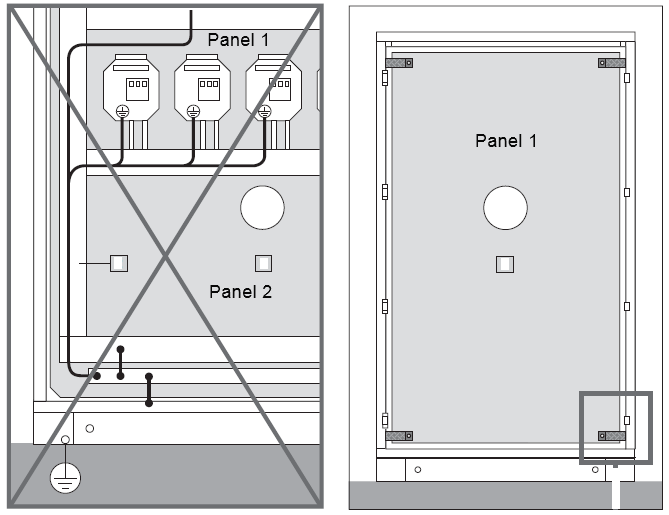

The wiring diagram of NK300CX or NK500 is as follows:

- Electrical control panel.

- Grounding cable: it connects with the grounding cable of the control cabinet. And its length should be shorter than 50cm and its radius not less than that of the machine power cable.

- Power cable: it connects to 220V AC power.

- USB interface: it connects to a mouse or a keyboard or a USB.

- Ethernet cable: it connects to an ethernet.

- VGA cable: it connects to a VGA display.

- DB9M/F cable: it connects to a Lambda.

- DB9M/F cable: it connects to a panel.

The requirements of wiring and grounding are as follows:

Wiring

To avoid the cable as the interference source, you need to keep the power cable away from the signal wires and shield them from interference.

Cables outside the control cabinet should be shielded wires.

Grounding

When NK300CX or NK500 is grounded, to restrain interference out of the control cabinet, you need to connect the grounding cable of NK300CX or NK500 to the PE terminal.

Grounding should be good and reliable, and grounding resistor greater than 4Ω.

To reduce impedance, all conductive materials should be grounded.

When the electrical control panel is grounded, you need to choose a whole metal panel, and connect it to the ground rod or the PE wire in the factory with a grounding cable.

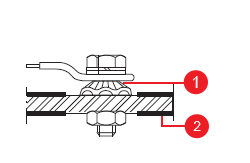

When the grounding cable connects to the control cabinet, you need to remove the oil paint at the fixed position and fasten the serrated washers and screws.

1. Serrated washer 2. Oil paint