Frequently Asked Questions(FAQ)

This section contains answers to common questions in NcStudio V10 Glass Cutting CNC System.

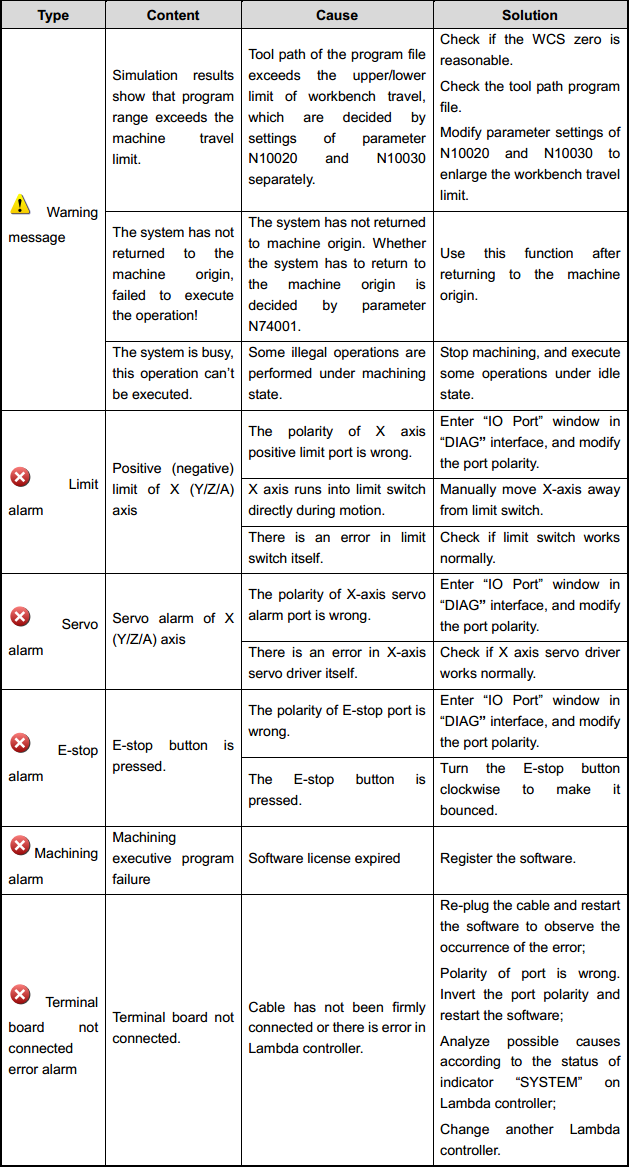

The origin signal cannot be detected during returning to machine origin.

Cause

Errors may exist in origin switch.

Troubleshooting

The direction of the machine during returning to machine origin is wrong.

Cause

The polarity of the origin signal is wrong.

Set related parameters incorrectly.

Troubleshooting

The polarity of the origin signal is N when the origin switch is normally open; otherwise, it is P.

Check parameter N74020 Coarse Locating Direction, and change the value of the parameter accordingly.

Coarse positioning speed is low during returning to machine origin.

Cause

The set value of parameter N74030 Coarse Locating Velocity is too small.

The polarity of the origin signal in the software does not match the type of the origin switch. If the origin switch is normally close, and the polarity of the origin signal is N, the machine will move away from the origin at fine positioning speed.

Troubleshooting

Modify the value of parameter N74030 Coarse Locating Velocity.

Modify the polarity of the origin signal according to the type of the origin switch.

The machine air cyclinder does not plunge cut after  is clicked in machine control bar on the software interface.

is clicked in machine control bar on the software interface.

Troubleshooting

In auto mode, check whether

turns green after being clicked.

turns green after being clicked.Click Port. Check the red dot ahead of output port Analog Enable turns green and outputs.

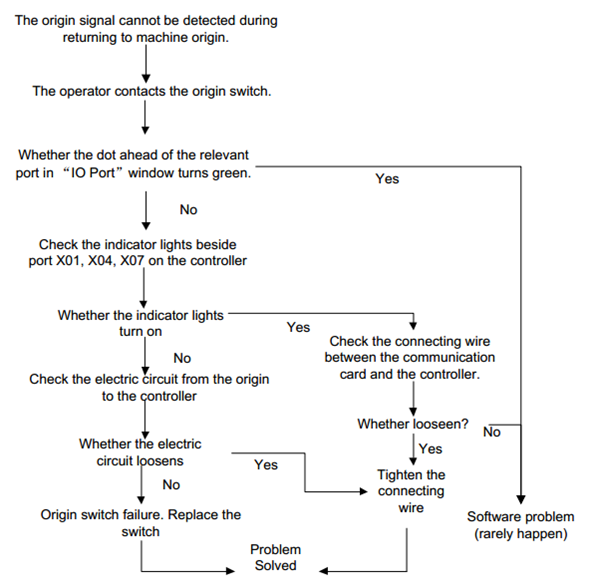

Check whether the output port Y02 on the terminal board outputs.

If the port outputs, then the software is proved connected with the hardware.

Check whether the proportional electro-magnetic valve has been connected with the output port Y02 on the terminal board correctly.

See following figure for wiring:

If the problem remains, use the multimeter to detect ends of ports Y02 and GND, or the analog voltage between Proportional Valve Signal Line and Proportional Valve.

Check whether the wiring between the proportional valve and the terminal board loosens.

If the wiring loosens, reconnect it.

A-axis rotates incorrectly during machining toolpath.

Troubleshooting

Modify the value of parameter N83013 Angle for Tool Turning. The suggested value is 60°.

If the angle of the adjacent two lines is about 60° by visual measurement, and A-axis still rotates incorrectly, please modify the value of the parameter to no more than 59°.

The boundary angle value of the adjacent lines is prone to error. For example, the actual angle of the adjacent lines is 59.99°, while it is shown as 60° in the software. Therefore, it is necessary to continually modify the value until the problem is solved.

The machine shakes during machining ellipse.

Cause

If the value of parameter N64100 Max Linear Machining Acceleration is too great, such as 160000mm/min, the machine will shake during machining of ellipse (about 200*150mm).

Troubleshooting

Set the value of parameter N64120 Max Control Acceleration as twice to five times that of parameter N64100 Max Linear Machining Acceleration.

Increase the value of parameter N64208 Reference Circle Max Velocity to a greater value, such as 5000mm/min or 10000mm/min.

Set the value of parameter N64207 Limit Arc Velocity as No.

Software expired.

Cause

Attachment destroyed.

Drive expired.

Troubleshooting

Change the attachment.

Unlock the drive with iMotion software.

Exception prompt occurs during registering.

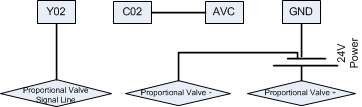

See the table below for details:

| Prompt | Cause | Solution |

|---|---|---|

| Registration failure! Invalid registration code! | The registration code is incorrect. | Ask the manufacturer to provide correct registration code, and register again. |

| Drive alarms. The alarm No. is 513. | Drive length of time registration expired. | Register length of time again. Unlock the drive with iMotion software. |

| Check wiring of driver N. | Set software parameters incorrectly. Set wiring/version/parameter of the drive incorrectly. |

Check parameters. Check wiring of the drive. |

| Registration failure. The N drive fails to register. | Problem of drive wiring. Problem of drive. |

Wiring problem: Check wiring of the drive. Driver problem: Change the drive. Other problems: Contact with WEIHONG. |

Alarm Information

NcStudio system stops when alarm information occurs. After the alarm is removed, it continues working.

Alarm information is in the table below: