Miscellaneous Operations

This chapter mainly introduces the following miscellaneous operations of NcStudio V10:

View Diagnosis

Diagnosis information includes the following:

View Log

Log information includes operating information, workpiece coordinate information, alarm information, etc.

To view log information, do the following:

Click Machine Tool → Log. A dialog box named Diagnosis pops up:

Click the button at the bottom of the dialog box to view corresponding information.

Please clean system log regularly. Excessive logs slow down the performance and responsiveness of the system.

View Port

Please refer to Detect I/O Port for details.

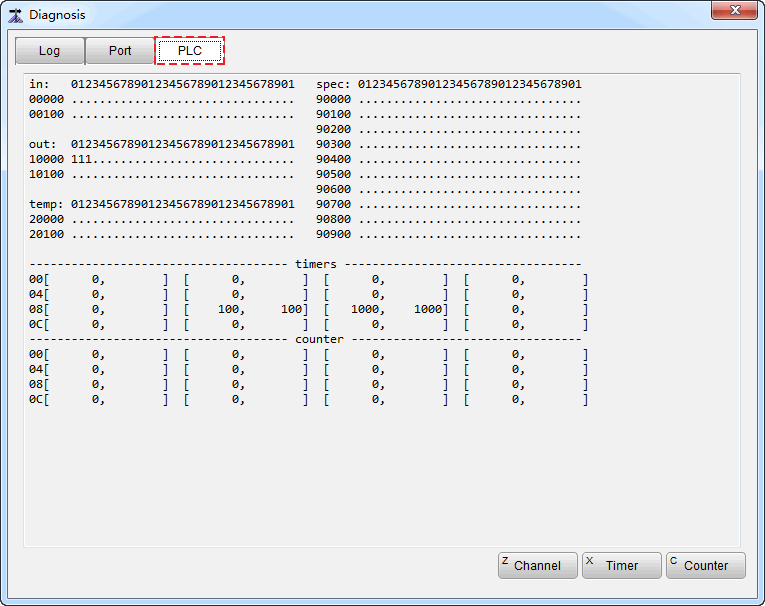

View PLC

With built-in PLC module of NcStudio software, output port can be controlled by PLC.

PLC information is used in PLC commissioning. Generally, this function is used by debugging personnel. For details, please refer to NcStudio Programming Manual.

To view PLC information, do the following:

Click Machine Tool → Log. A dialog box named Diagnosis pops up.

Click PLC to switch to PLC interface:

Double click the buttons at the bottom of the dialog box, and enter Channel, Timer and Counter.

Click OK.

Compensate Screw Error

Screw error compensation includes pitch error compensation and backlash compensation.

Compensate Backlash

The spindle is fixed on the screw. There exists difference between screw external thread and internal thread. When spindle moves in one direction, it must go through the error between threads. Such error compensation is called backlash compensation.

To compensate backlash, do the following:

Measure screw error with dedicated gauge.

Fix the gauge on spindle. And rotate the meter pointer to origin.

Manually move the meter pointer by a millimeters, and move the pointer in the reverse direction by a millimeters. If the meter pointer moves by b millimeters actually, then the backlash is (a-b) millimeters.

Click Parameter. A dialog box pops up.

Click Manufacturer. Set value of parameter N12010~12013 Backlash that corresponds to the axis to (a-b).

Restart the software.

Compensate Pitch Error

Calculation formula:

Error = Actual machine coordinate - Nominal machine coordinate

To compensate pitch error, do the following:

List the modification value of each point on error curve in a table. And save the table in CNC system memory.

Click Parameter. A dialog box pops up.

Click Manufacturer.

Set the following parameters:

Set the value of parameter N12000 Enable Leadsrew CMPN as Yes.

Set the value of parameter N12001 Only Backlash CMPN as No.

Restart the software.

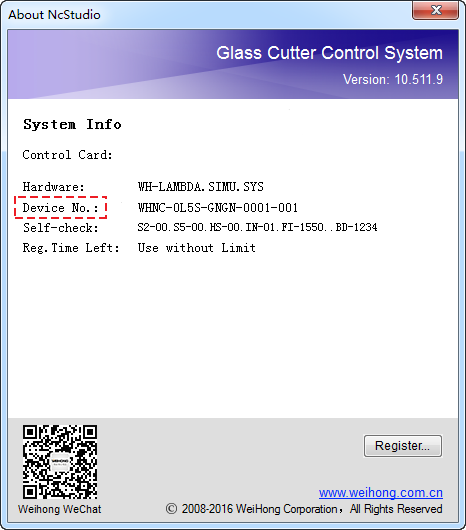

Register

Registration function is used to register use time of card and drive.

Get a Regiatration Code

You can get a registration code either in WeChat or via the manufacturer.

Before getting a registration code, click Help → About NcStudio to get the Device No.:

To get a registration code, do one of the following:

Do the following to get a registration code in WeChat:

Enter WEIHONG official account in WeChat.

Click Service → Register → Activate Account to register.

Return to Log In page. Fill in the blanks, and click Log in to jump to Time page.

On Time page, enter related information.

Click Generate.

Do the following to get a registration code via manufacturer:

Send device No. to manufacturer.

Ask the manufacturer to use APP “NcStudio Generator” to generate a registration code.

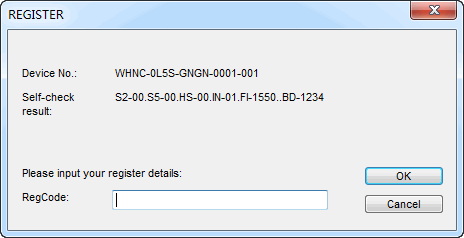

Register in NcStudio

To register in NcStudio, do the following:

Click Help → About NcStudio → Register.

A dialog box named REGISTER pops up:

Fill in Registration code.

Click OK.

Registration completes.

If drive registration enabled, card and drive will be registered at the same time.

If exception prompt occurs during registering, please refer to Exception prompt occurs during registering.

Use NcCloud

NcCloud, independently developed by WEIHONG, is a system of cloud-based monitoring and control.

To use NcCloud, click Help → NcCloud. NcCloud Assitant pops up.

Please refer to NcCloud Assistant User Manual for details.