Measure Height with the Cylinder

This operation is used to measure height by traditional contact measuring method.

Prepared Work

Before measuring height with the cylinder, ensure the following:

The target workpiece has been placed on the workbench.

The parameter N79201 Software Configuration has been set to 1.

Z-axis has returned to the machine origin.

The workpiece origins of X-axis and Y-axis have been defined.

Operation

To measure height, do the following:

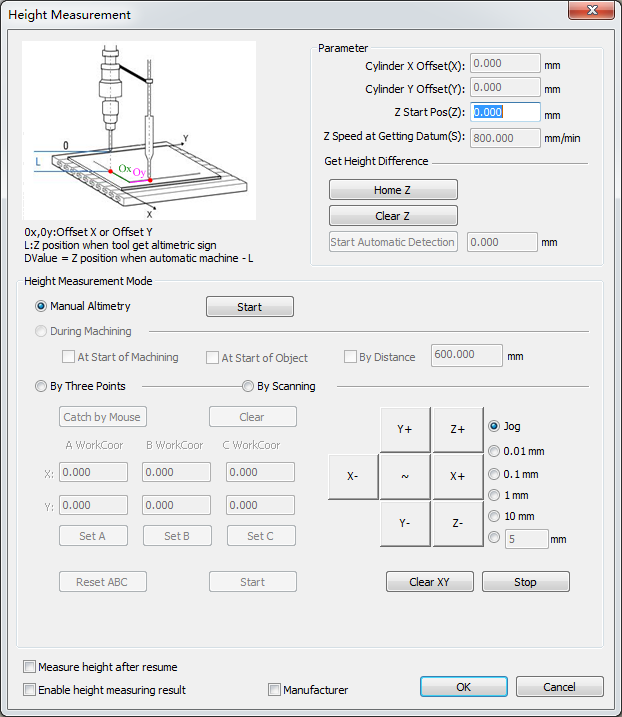

In the manual mode, click Altimetry in the operation button bar. Height Measurement dialog box pops up:

To enable manufacturer permission, check Manufacturer in the bottom, and input the manufacturer password.

In Parameter area, according to the actual situation, set parameters Z Start Pos and Z Speed at Getting Datum.

To set parameters Cylinder X Offset and Cylinder Y Offset, do the following:

Move the tool head to the proper position, click Clear XY and punch a hole on the workpiece.

Open the cylinder of height measuring sensor and push out the height measuring sensor.

To move the laser spot to the hole center, turn on laser and move X-axis and Y-axis.

Respectively input the current workpiece coordinates in Cylinder X Offset and Cylinder Y Offset input boxes.

To get the height difference, do the following:

Manually move the abrasive tube to the cutting height and click Clear Z.

Click Start Automatic Detection.

After detection, the system automatically fills in height difference.

To measure height with the cylinder, in Height Measurement Mode area, select one of the following measuring methods:

Note: The result of height measurement is still effective after reloading the program file or restarting the software. To disable the result, please uncheck Enable height measuring result in Height Measurement dialog box .

To measure height during breakpoint resume, check Height measuring or not when resume.

Parameter

Cylinder X Offset: The offset of height measuring unit relative to the tool head in X-axis direction.

Cylinder Y Offset: The offset of height measuring unit relative to the tool head in Y-axis direction.

Z Start Pos: The machine coordinate of Z-axis before starting height measurement.

Z Speed at Getting Datum: The speed of Z-axis at the time of getting datum position.

Execute Manual Height Measurement

This operation is used to measure height for a single-point, and execute tool calibration by one key which saves troubles of tool calibration by clearing.

To execute manual height measurement, do the following:

Move the tool head to the target measuring point.

In Height Measurement Mode area of Height Measurement dialog box, select Manual Altimetry.

Click Start. Height measurement starts.

During height measurement, you can do the following if there is something wrong:

If exceptions in the height measuring unit occur, measuring position is incorrect, or it is going to collide with the machine tool, click Stop to stop height measurement.

If the toolpath origin is set incorrectly, correct it, click XY Clear to clear workpiece coordinate of X-axis and Y-axis in the correct position, and measure height again.

Execute In-process Height Measurement

This operation is used to measure height during cutting. And it is applicable to the workpiece with a relatively hard and smooth surface, whose machining effect is not influenced by scratches.

To execute in-process height measurement, do the following:

In Height Measurement Mode area of Height Measurement dialog box, select During Machining.

To select the start point for height measurement, do one of the following:

Check At Start of Machining. Height measurement starts at the start point of program file.

Check At Start of object. Height measurement starts at the start point of each object.

Check By Distance and set the distance between the workpiece surface and tool head. If the actual distance is equal to the set distance during cutting, height measurement starts.

Click OK. Height measurement starts.

Execute Three-point Height Measurement

This operation is used to identify a plane through three points. And it is applicable to the workpiece with an even surface and a tilt angle relative to the workbench.

To execute three-point height measurement, do the following:

In Height Measurement Mode area of Height Measurement dialog box, select By Three Points.

To get three points (A, B, C) within the workbench, do one of the following:

Manually input workpiece coordinates of A, B and C.

Respectively move X-axis and Y-axis to A / B / C and click Set A / Set B / Set C. A, B and C are set as a measuring point.

If you are not satisfied with the results, click Reset ABC and reset them.

To directly pick A, B and C on the object, click ABC by mouse and select three points in POS window.

If you are not satisfied with the results, click Clear and reset them.

Click Start. Height measurement starts.