Set Tool Compensation

This operation is used to compensate the tool diameter on the designed machining dimension, so as to reduce the offset between the actual machined dimension and designed dimension, which is caused by the tool diameter.

To set tool compensation, do the following:

In NcEditor, click

and select the target object.

and select the target object.Click

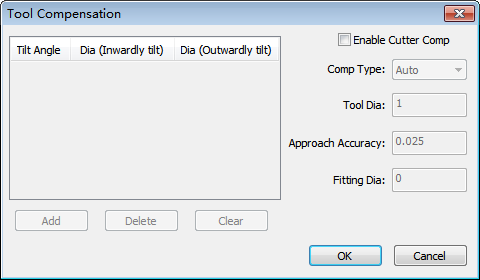

in the tool bar. Tool Compensation dialog box pops up:

in the tool bar. Tool Compensation dialog box pops up:

Check Enable Cutter Comp and select a type of tool compensation:

Auto: The system will automatically set the position of tool compensation according to the groove direction. The default position is at the side of toolpath in the scrap region.

Left: Along the machining direction, compensate the tool diameter on the left of workpiece.

Right: Along the machining direction, compensate the tool diameter on the right of workpiece.

Tilt angle: The kerf width differs in the tilt angle. According to different tilt angles, compensate the corresponding tool diameter.

According to the actual tool diameter, set parameter Tool Dia.

Click OK.

To delete added tool compensation, select the target object and do one of the following:

In the tool bar, click

.

.In Tool Compensation dialog box, uncheck Enable Cutter Comp and click OK.